Narrow single paper glazing ink-jet coding platform and working method thereof

A single-sided, narrow-width technology, which is applied in the field of glazing inkjet printing equipment, can solve the problems of static electricity, dust and surface adhesion of narrow-width box-type paper, and achieve the effect of complete functions and improved productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

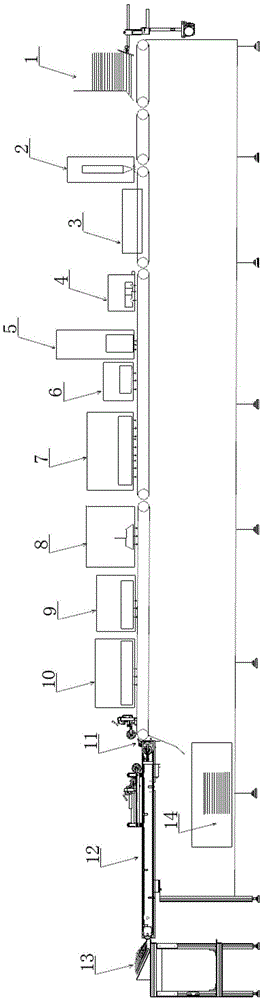

[0020] Embodiment: a kind of narrow format single-fed paper glazing inkjet coding platform (see figure 1 ), including a paper feeding unit 1, a coding unit 5, an LED drying unit 6, and a stacking delivery unit 13; it is characterized in that a corona unit 2 and an electrostatic precipitator unit 4 are installed at the input end of the coding unit 5; A glazing unit 7 , a detection unit 8 , an infrared drying unit 9 , and an ultraviolet drying unit 10 are sequentially installed on the output end of the LED drying unit 6 .

[0021] A deviation correction unit 3 is installed between the corona unit 2 and the electrostatic precipitator unit 4 . (See figure 1 )

[0022] The glazing unit 7 adopts a structure of several sets of spray head assemblies, and the spray head assemblies perform varnish spraying on the variable information that needs to be sprayed on the surface of the paper under the action of the control system.

[0023] The spraying variable information is a barcode, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com