Automatic chained right-angle de-consolidation mechanism

A distribution mechanism and chain technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high equipment cost, low equipment use efficiency, low production efficiency, etc., and achieve low error rate and distribution. The effect of high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

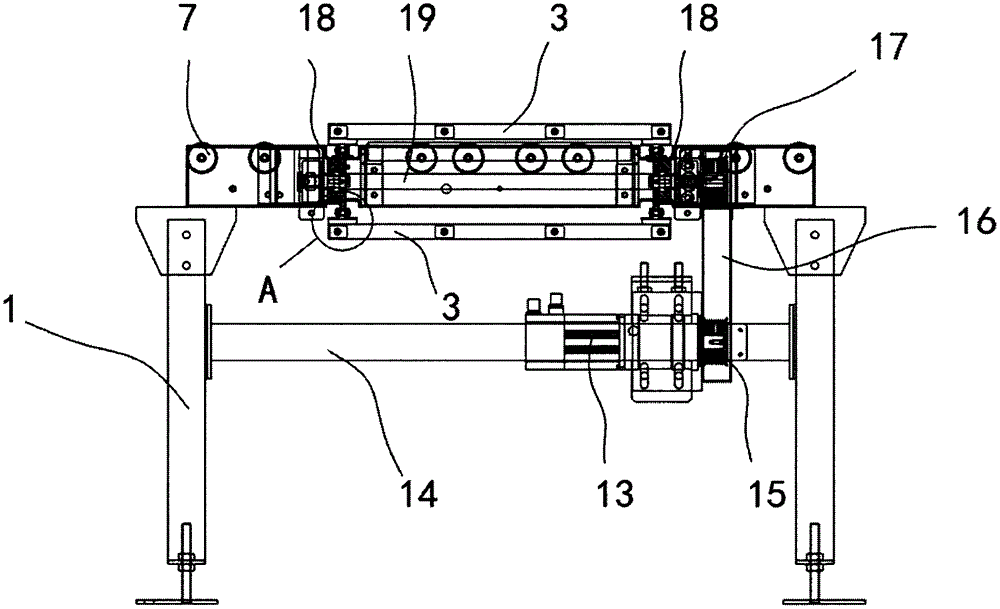

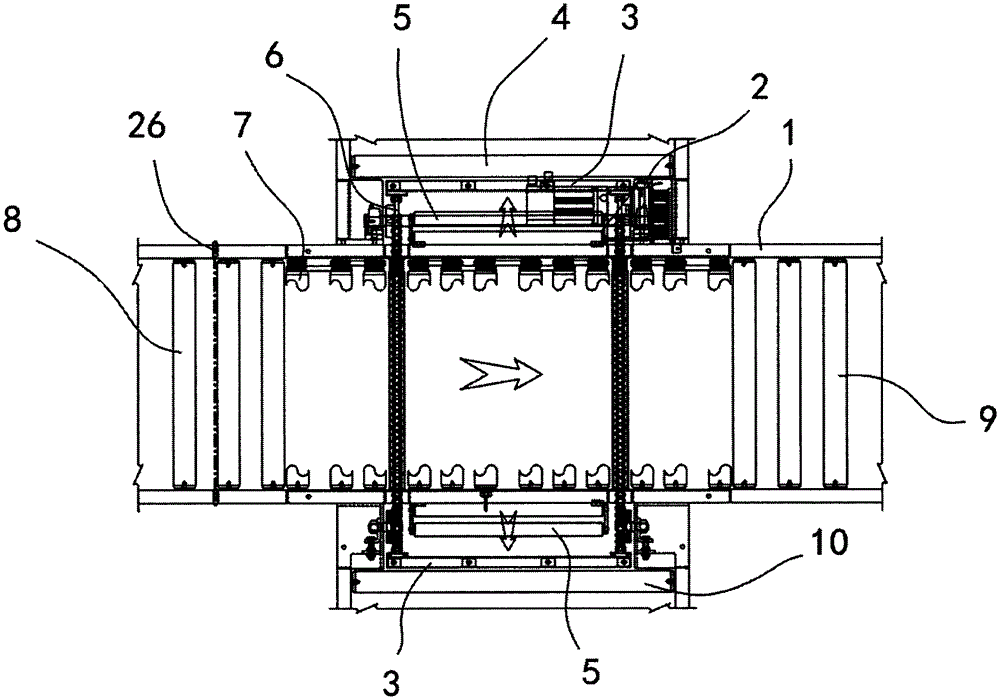

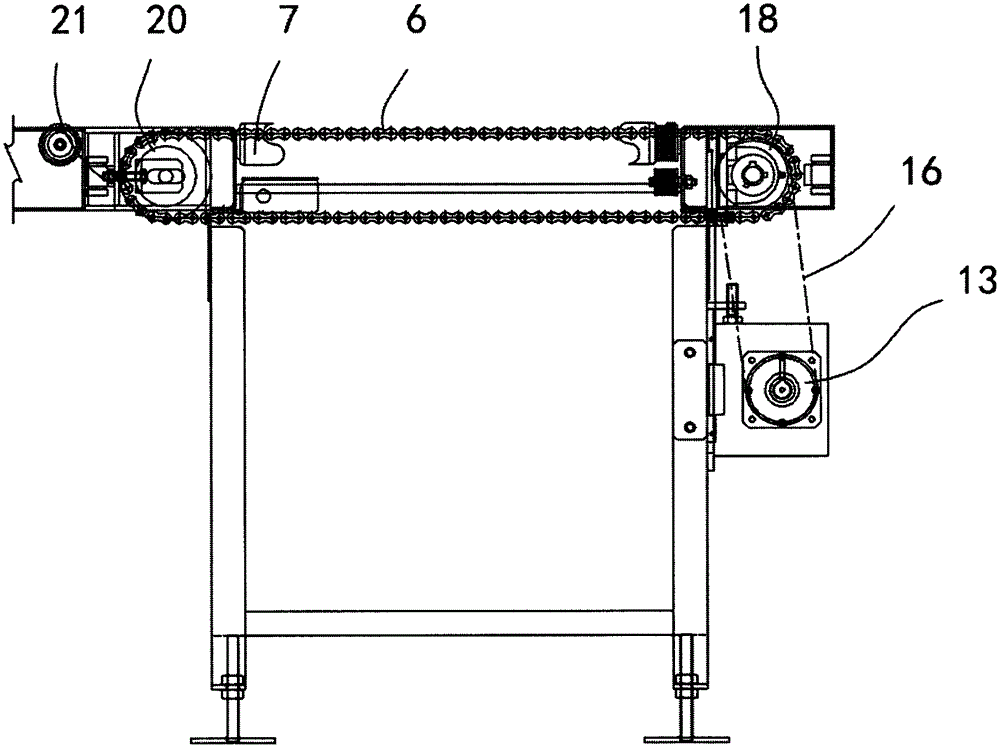

[0013] Example: such as Figures 1 to 4 Shown is an embodiment of an automatic chain-type right-angle distribution mechanism of the present invention. In this embodiment, an automatic chain-type right-angle distribution mechanism includes a frame 1, and a conveying line 7 is arranged on the frame 1. The frame 1 is also provided with at least two circulating chains 6 parallel to each other and perpendicular to the conveying line 7, the circulating chain 6 is fixed with a distribution rod 3, and the distribution rod 3 is located on the Above the conveying line 7 , the circulating chain 6 is driven by a driving motor 13 , and a contrast photoelectric instrument 26 is arranged at the entrance of the conveying line 7 .

[0014] In this embodiment, an input line 8 is provided at the entrance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com