A type wheel and its assembly method

An assembly method and the technology of the I-shaped wheel, which are applied in the field of winding equipment, can solve problems such as increasing production costs, and achieve the effects of reducing transportation costs, convenient production, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

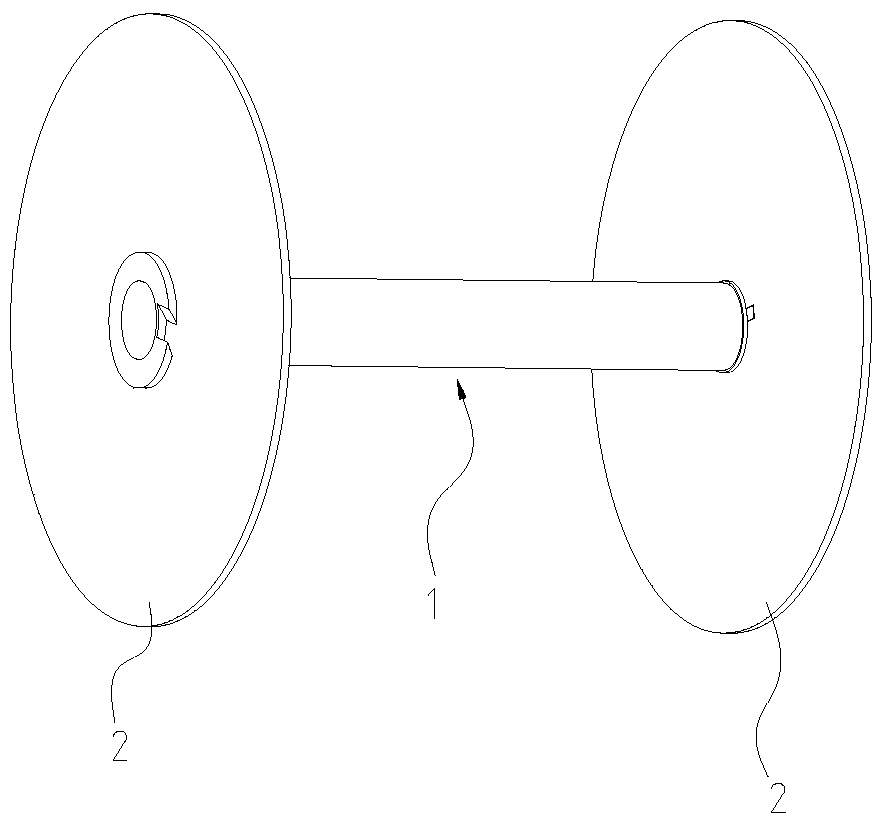

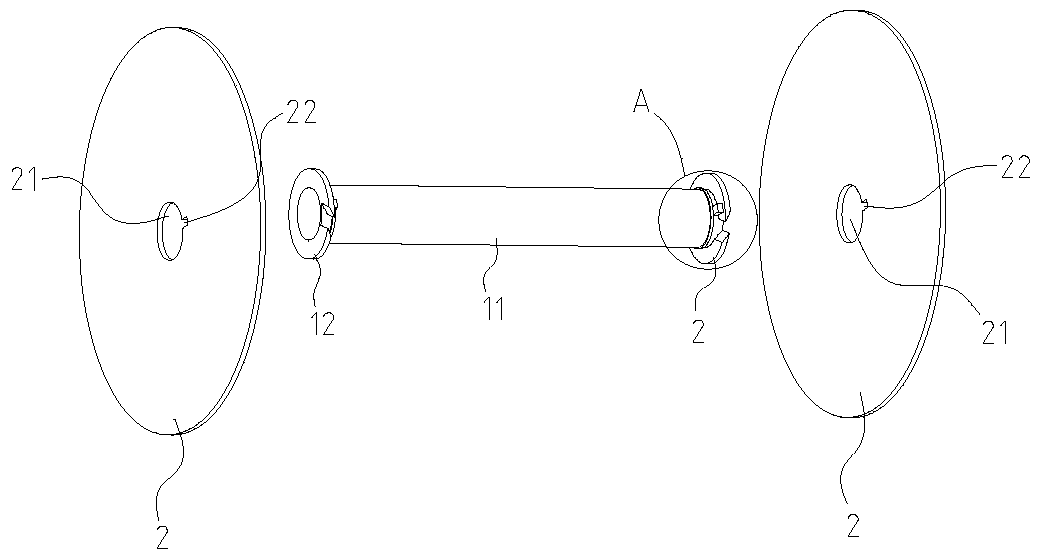

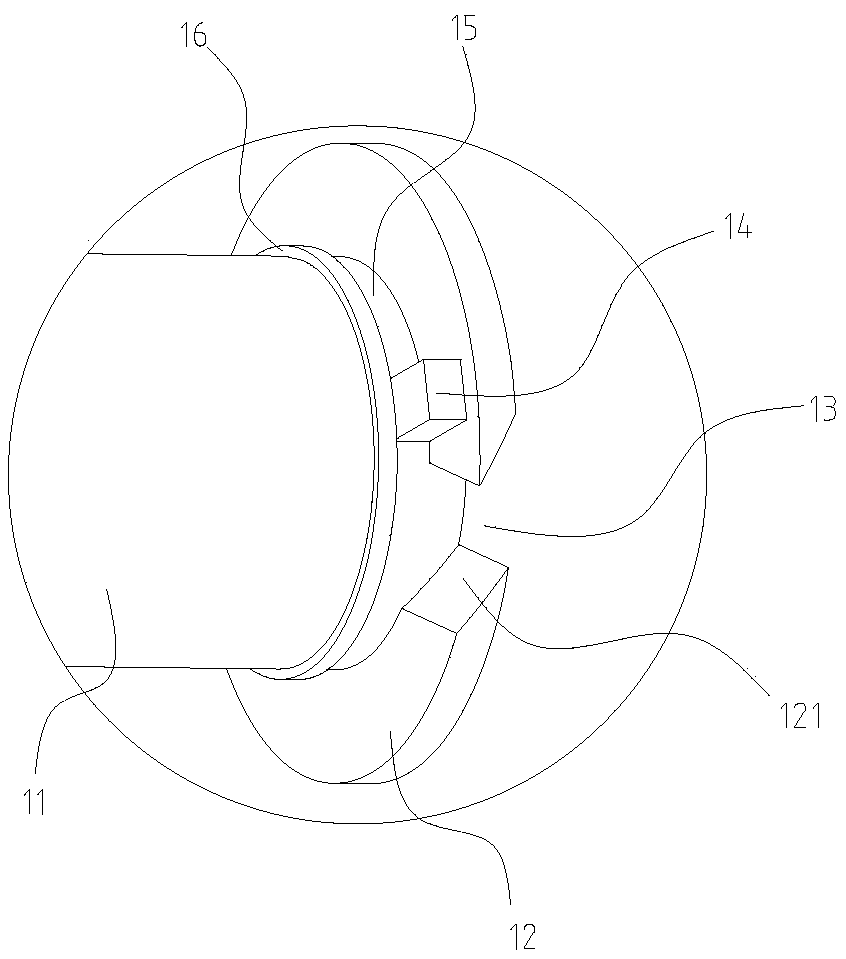

[0026] Such as figure 1 As shown, an I-shaped wheel includes a roll body 1 and baffles 2 arranged at both ends of the roll body 1, and the baffles 2 and the roll body 1 are detachable. Such as figure 2 , 3 As shown, the reel body 1 is integrally injection-molded by plastic, which includes a coiled tube 11 and ribs 12 arranged at both ends of the coiled tube 11; the ribs 12 are circular, and the diameter of the ribs 12 is larger than that of the coiled tube 11, the rib 12 has a certain thickness, and the rib 12 plays the role of restricting the baffle 2 from the coil 11. The research shows that the diameter of the rib 12 is 25~65mm, and the inner diameter of the coil 11 is 18~ 50mm, the round edge of the reel body 1 has good strength, ingenious design, convenient assembly, and lower cost; the end of the coil 11 is provided with an annular protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com