A kind of felt sole dipping solution and preparation method of dipping felt sole, a kind of shoe

A technology of dipping liquid and felt, which is applied in the field of preparation of felt sole dipping liquid and dipped felt sole, which can solve the problems of insufficient wear resistance, easy breakage of the outsole, and waste, so as to improve wear resistance and save costs , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

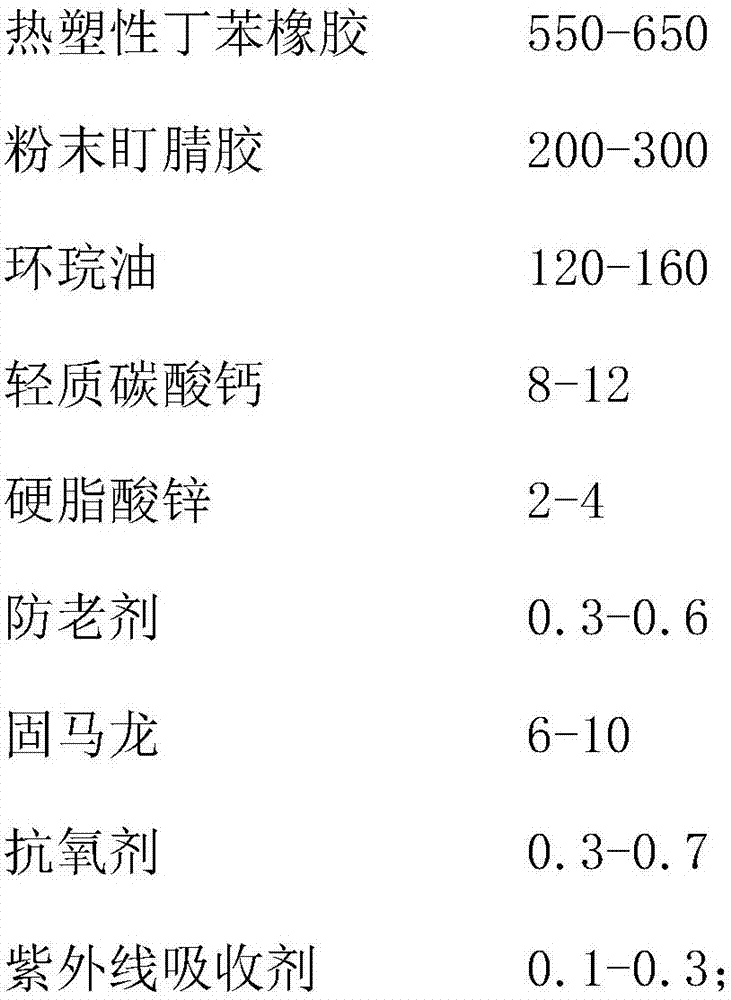

[0040] A kind of felt sole dipping liquid, comprises the raw material of following percentage by weight:

[0041] TPR particles 40%

[0042] Dichloromethane 60%;

[0043] Mix the TPR particles and dichloromethane according to the formula ratio, stir evenly, soak and swell at 27° C. for 48 hours, and obtain a dipping solution for felt soles.

[0044] The preparation method of described TPR particle is:

[0045] (1) Put 15kg of environmental oil into a container pot and heat and stir. When the heating temperature reaches 100°C, add 0.3kg of zinc stearate, 50g of anti-aging agent, 0.8kg of Gumalone, 50g of antioxidant, and 20g of ultraviolet absorber Continue to stir, stir well after 20 minutes;

[0046] (2) Pour 60kg of thermoplastic styrene-butadiene rubber YH-805 (SBS4452) and 25kg of powdered nitrile rubber into the pot and continue stirring. After 40 minutes, the raw materials are completely absorbed.

[0047] (3) Then pour 1kg of light calcium carbonate into the pot and...

Embodiment 2

[0053] A kind of felt sole dipping liquid, comprises the raw material of following percentage by weight:

[0054] TPR particles 45%

[0055] Dichloromethane 55%;

[0056] Mix the TPR particles and dichloromethane according to the formula ratio, stir evenly, soak and swell at 30° C. for 48 hours, and obtain a dipping solution for felt soles.

[0057] The preparation method of described TPR particle is:

[0058] (1) Put 14kg of environmental oil into a container pot and heat and stir. When the heating temperature reaches 100°C, add 0.2kg of zinc stearate, 40g of anti-aging agent RD, 0.6kg of Gumaron C-80, and 50g of antioxidant MB264 , 30g ultraviolet absorber phenyl salicylate continue to stir, stir evenly after 20 minutes;

[0059] (2) Pour 58kg of thermoplastic styrene-butadiene rubber YH-805 (SBS4452) and 28kg of powdered nitrile rubber P830 into the pot and continue stirring. After 40 minutes, the raw materials are completely absorbed.

[0060] (3) Then 1.1kg of light c...

Embodiment 3

[0066] A kind of felt sole dipping liquid, comprises the raw material of following percentage by weight:

[0067] TPR particles 38%

[0068] Dichloromethane 62%;

[0069] Mix the TPR particles and dichloromethane according to the formula ratio, stir evenly, soak and swell at 28° C. for 48 hours, and obtain a dipping solution for felt soles.

[0070] The preparation method of described TPR particle is:

[0071] (1) Put 16kg of ring oil into a container pot and heat and stir. When the heating temperature reaches 100°C, add 0.4kg of zinc stearate, 55g of anti-aging agent RD, 0.7kg of Gumaron C-80, and 57g of antioxidant MB264 10g UV absorber phenyl salicylate continued to stir, and stirred evenly after 20 minutes;

[0072] (2) Pour 60kg of thermoplastic styrene-butadiene rubber YH-805 (SBS4452) and 24kg of powdered nitrile rubber P830 into the pot and continue stirring. After 40 minutes, the raw materials are completely absorbed.

[0073] (3) Then 1.1kg of light calcium carbona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com