Ferrous coating improver based on inland saline-alkali land

A technology for improving agent and saline-alkali land, applied in agricultural machinery and implements, agricultural, chemical instruments and methods, etc., can solve the problems of ferrous sulfate easy to absorb moisture and agglomerate, the effect of soil acid regulation is weakened, and the difficulty of application is increased, so as to improve crops. Nutritional function, high practical value, the effect of avoiding oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

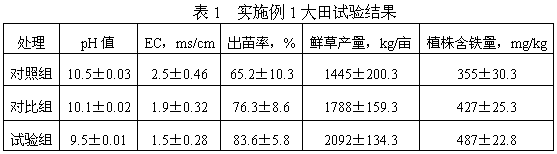

Embodiment 1

[0025] Take by weighing 20kg of dried lemongrass leaves, 20kg of dried Jerusalem artichoke leaves, 20kg of dried Tamarix leaves, and 40kg of dried walnut green peels, and after air-drying, pulverize and cross a 40-mesh sieve for subsequent use.

[0026] Weigh 100kg of sulfur, 400kg of ferrous sulfate, 50kg of iron powder, 50kg of oxalic acid, 200kg of potassium humate, and 50kg of bentonite, and pass through a 40-mesh sieve after crushing.

[0027] Weigh 250 g of polyvinylpyrrolidone and dissolve it in 50 kg of water to make an aqueous binder solution.

[0028] Add crushed and sieved sulfur, ferrous sulfate, iron powder, dried lime leaf powder, dried artichoke leaf powder, dried tamarisk leaf powder, dried walnut green peel powder, oxalic acid, potassium humate, and bentonite into the mixer and stir evenly , into the disc granulator, evenly spray the binder aqueous solution, mix and granulate to make the core core of the coating modifier.

[0029] Weigh 50kg of sulfur, melt i...

Embodiment 2

[0039] Take by weighing 10kg of dried lemongrass leaves, 20kg of dried Jerusalem artichoke leaves, 20kg of dried tamarisk leaves, 15kg of dried quinoa leaf powder, and 40kg of dried walnut green peels, air-dried and crushed through a 40-mesh sieve for subsequent use.

[0040] Weigh 50kg of sulfur, 500kg of ferrous sulfate, 65kg of iron powder, 80kg of oxalic acid, 100kg of potassium humate, 50kg of bentonite, and pass through a 40-mesh sieve after crushing.

[0041] Weigh 250 g of polyvinylpyrrolidone and dissolve it in 50 kg of water to make an aqueous binder solution.

[0042] Crushed and sieved sulfur, ferrous sulfate, iron powder, dried lime leaf powder, dried artichoke leaf powder, dried tamarisk leaf powder, dried quinoa leaf powder, dried walnut green bark powder, oxalic acid, potassium humate, bentonite Add it into the mixer and stir evenly, send it into the disc granulator, spray the binder aqueous solution evenly, mix and granulate to make the core core of the coatin...

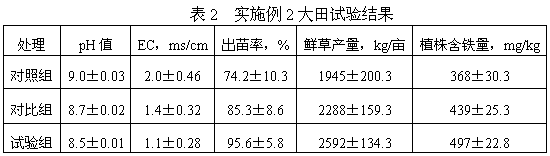

Embodiment 3

[0053] Take by weighing 10kg of dried Jerusalem artichoke leaves, 10kg of dried tamarisk leaves, and 30kg of dried walnut green skins, air-dried and pulverized through a 40-mesh sieve for subsequent use.

[0054] Weigh 50kg of sulfur, 550kg of ferrous sulfate, 100kg of iron powder, 50kg of oxalic acid, 100kg of potassium humate, 50kg of bentonite, and pass through a 40-mesh sieve after crushing.

[0055] Weigh 250 g of polyvinylpyrrolidone and dissolve it in 50 kg of water to make an aqueous binder solution.

[0056] Add the crushed and sieved sulfur, ferrous sulfate, iron powder, dried artichoke leaf powder, dried tamarisk leaf powder, dried walnut green peel powder, oxalic acid, potassium humate, and bentonite into the mixer and stir evenly, and then send them into the disc making machine. In the granulator, the aqueous binder solution is evenly sprayed, mixed and granulated to make the core core of the coating modifier.

[0057] Weigh 50kg of sulfur, melt it with a sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com