Manufacturing method of tapered bumper post

A technology of tapered and bumper, which is applied in the field of preparation of tapered bumpers, can solve the problems of poor weather resistance and anti-aging performance, poor fire resistance, poor weather resistance, and insufficient impact resistance, and achieve a full appearance and good weight loss effect, the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

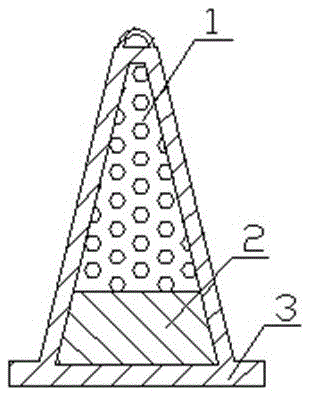

[0021] Such as figure 1 As shown, the tapered car bumper prepared by the preparation method of the tapered bumper of the present invention includes a tapered surface layer 3, a heavy filling material 2 and a light filling material 1 located in the tapered surface layer 3, and the The light filling material 1 is located above the heavy filling material 2 .

[0022] The preparation method of tapered car bumper of the present invention comprises the following steps:

[0023] (1) Make three left, right and lower molds, the three molds can be molded into a cone, the lower mold is trapezoidal, and the left and right molds are half a cone;

[0024] (2) Lay the fabric layer and glass fiber mesh cloth on the left and right molds respectively, then fill with light middle material, and then close the left and right molds;

[0025] (3) On the lower mold, lay the fabric layer and glass fiber mesh respectively, then fill with heavy materials, and finally close the lower mold with the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com