Intelligent exhaust system

An intelligent, detection and control system technology, applied in mine/tunnel ventilation, dust prevention, fire prevention, etc., can solve problems such as lack of good ventilation solutions, low visibility, and short fan exhaust distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

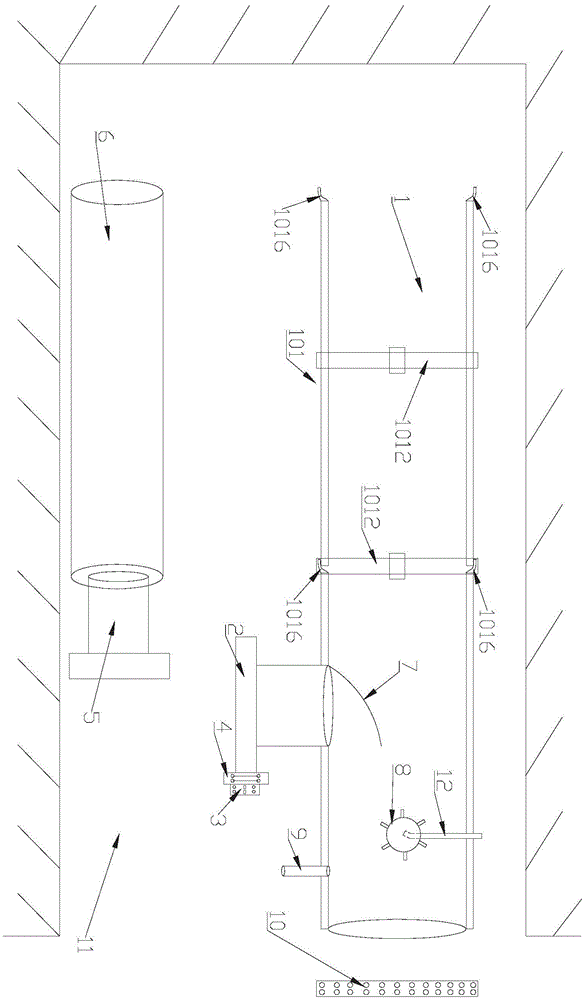

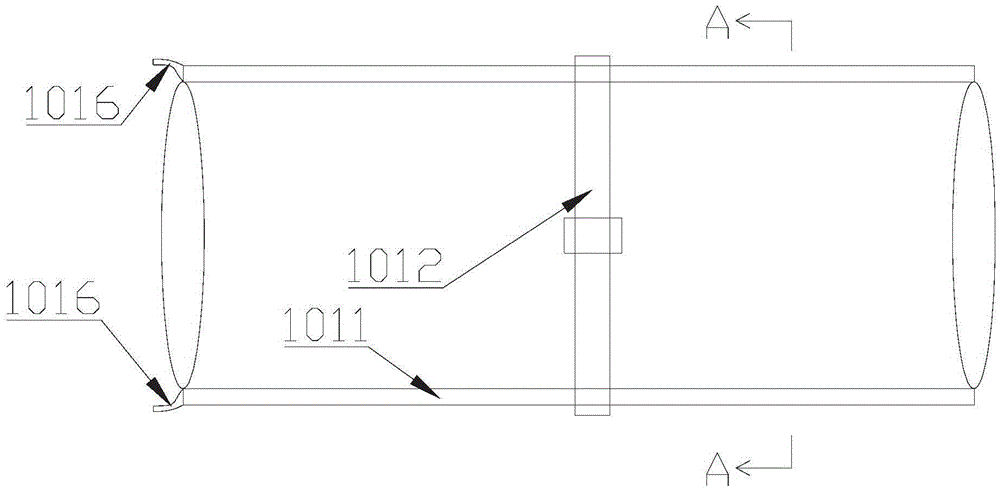

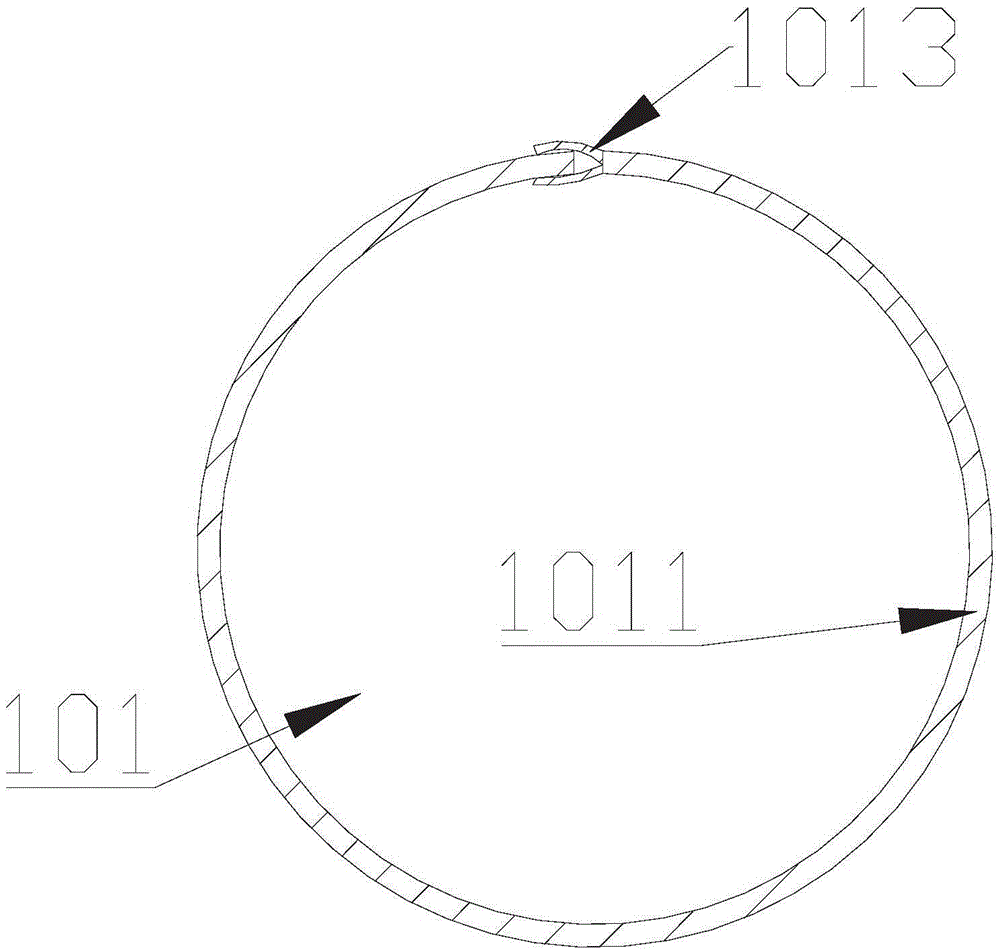

[0026] Figure 1 ~ Figure 4 It schematically shows an intelligent exhaust system according to an embodiment of the present invention. Such as figure 1 As shown, the intelligent exhaust system includes a ventilation duct 1 and a detection and control system. The ventilation duct 1 is provided with an exhaust fan 2 at intervals along the length direction. The detection and control system includes a detector 3 and a control host 4. The control host 4 and The exhaust fan 2 is connected, and the detector 3 is connected with the control host 4 . Its beneficial effect is, along the length direction of tunnel 11, vent pipe 1, exhaust fan 2, detection and control system are installed, hang on the top of tunnel 11, switch on power supply, when detector 3 detects harmful gas (such as sulfur dioxide or carbon monoxide ) or harmful solid particles (such as dust or smog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com