Heating device for fly ash autoclaved brick production

A technology for heating devices and autoclaved bricks, which is applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc. It can solve problems such as brick structure defects, reduce cost loss, improve processing efficiency, and prevent heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

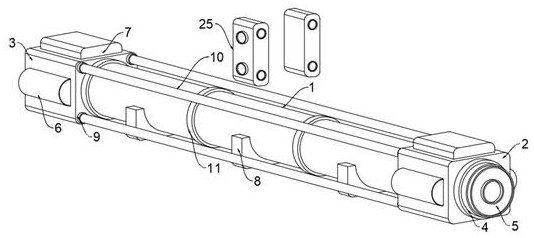

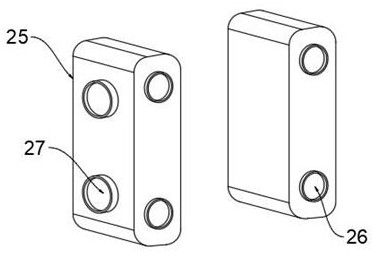

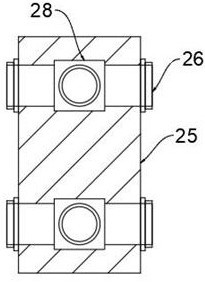

[0024] see Figure 1-5 , an embodiment provided by the present invention: a heating device for the production of fly ash autoclaved bricks, comprising a brick body heating steamer 1, a plurality of brick body heating steamer 1, and brick body heating steamer 1 Through the connection of the flange hoop 11, different numbers of brick heating and steaming tanks 1 can be selected for combined use according to different processing conditions, thereby improving processing efficiency. One end of the brick heating and steaming tank 1 is provided with a first tank adapter box 2, and the other end of the brick body heating steam tank 1 is provided with a second tank transfer b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com