Novel anti-scouring adjusting valve

A regulating valve and anti-scouring technology, applied in the direction of valve details, valve devices, valve energy absorption devices, etc., can solve the problems of fast flow rate, high medium pressure, poor adjustment effect, etc., to reduce flow rate and reduce pressure , The effect of balancing and stabilizing the medium flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

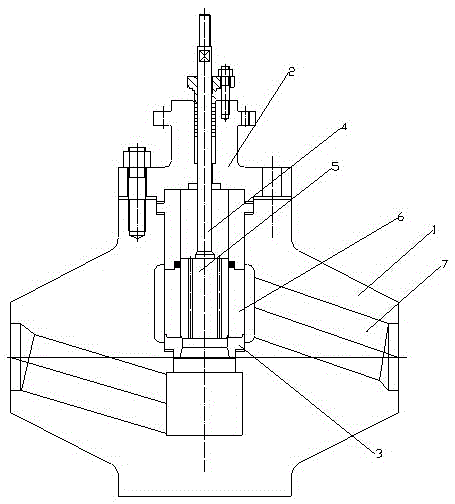

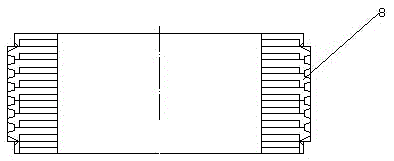

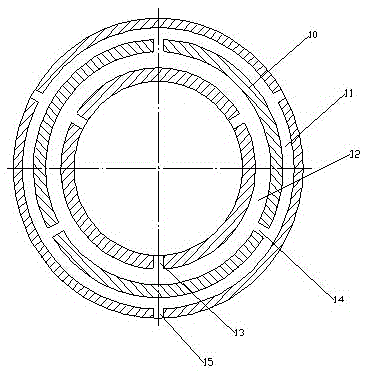

[0017] like figure 1 A novel anti-scouring regulating valve shown includes a valve body 1 , a valve cover 2 , a valve seat 3 , a valve stem 4 , a valve core 5 and a throttling element 6 .

[0018] On the upper end of the valve body 1, there is a valve cover 2 used in conjunction with it. The valve cover 2 is fixed between the valve body 1 by bolts. In the valve body 1, there is a channel 7 for medium circulation and a valve stem 4. A movable cavity, the valve stem 4 extends from the middle of the valve cover 2 into the cavity of the valve body 1 from top to bottom, a valve core 5 is connected to the lower end of the valve stem 4, and a valve core 5 is arranged below the valve core 5 The valve seat 3 installed on the valve body 1, and the sealing surface of the valve core 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com