Determination method for fracture toughness of actual cracked structure

A technology of fracture toughness and determination method, which is applied in the direction of testing the strength of materials by applying stable tension/pressure, which can solve problems such as difficulty in fracture toughness and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

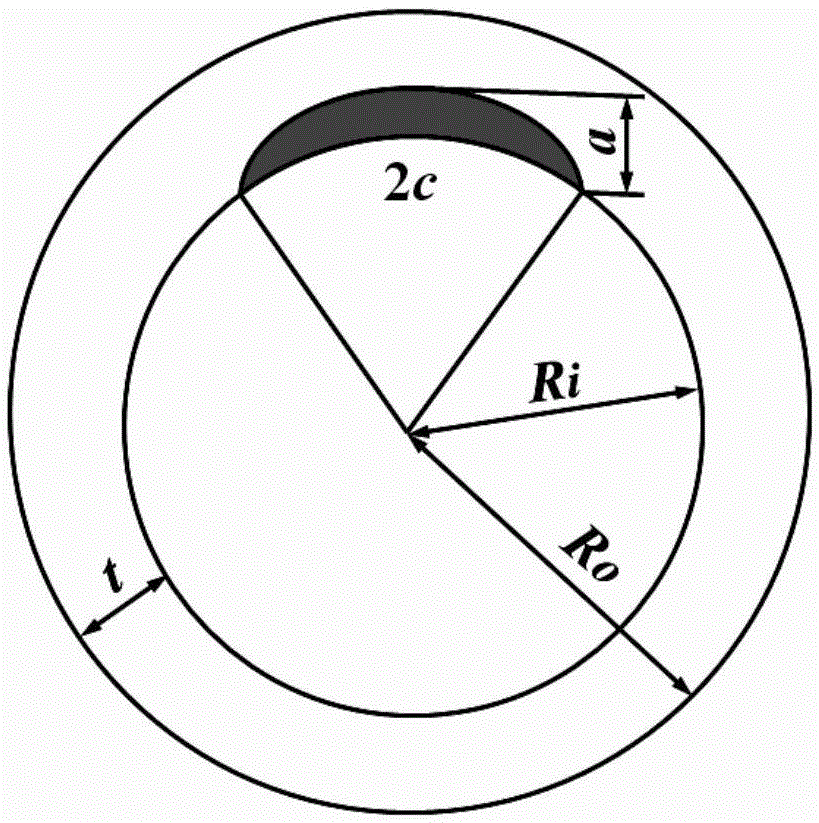

[0020] The specific steps of the method for determining the fracture toughness of the actual crack-containing structure include:

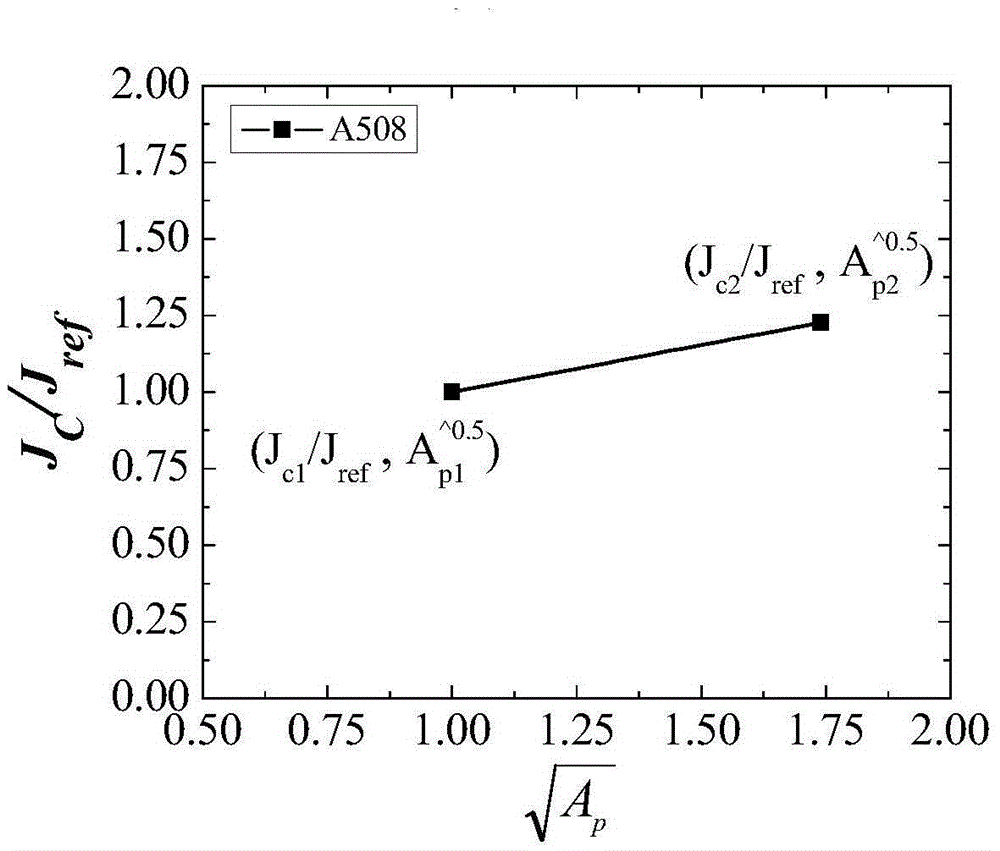

[0021] 1. The fracture toughness J of the materials used in the structure C with uniform constraint parameter A p Determination of associated lines:

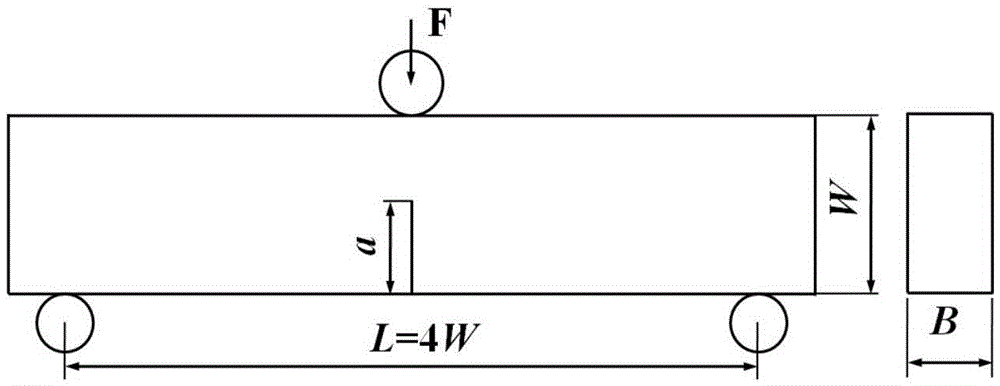

[0022] (1) According to the ASTME1820 standard, select a sample of a certain size as the standard sample, and then select at least one group of non-standard size samples (more accurate results can be obtained with more samples), and perform fracture mechanics on the selected samples. Experiment to measure the fracture toughness of the specimen J C .

[0023] (2) Establish a finite element model for the selected sample, and calculate the area A enclosed by the contour line of the crack tip PEEQ=0.2 (or 0.3) corresponding to the fracture toughness of different samples PEEQ .

[0024] (3) Choose the fracture toughness J measured by the above-mentioned standard sample C And the area enclosed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com