Fingerprint sensor

A fingerprint sensor and fingerprint signal technology, applied in the field of sensors, can solve the problems such as the inability to improve the length of the amorphous silicon glass panel and the flexible circuit board 24, and increase the area of the substrate product, so as to save the glue bonding area and save the The effect of reducing the area and reducing the cost of device manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It can be seen from the background technology that how to effectively connect the readout circuit chip and the amorphous silicon TFT photosensitive panel, improve the signal-to-noise ratio, simplify the system complexity, and reduce the system size is a key issue.

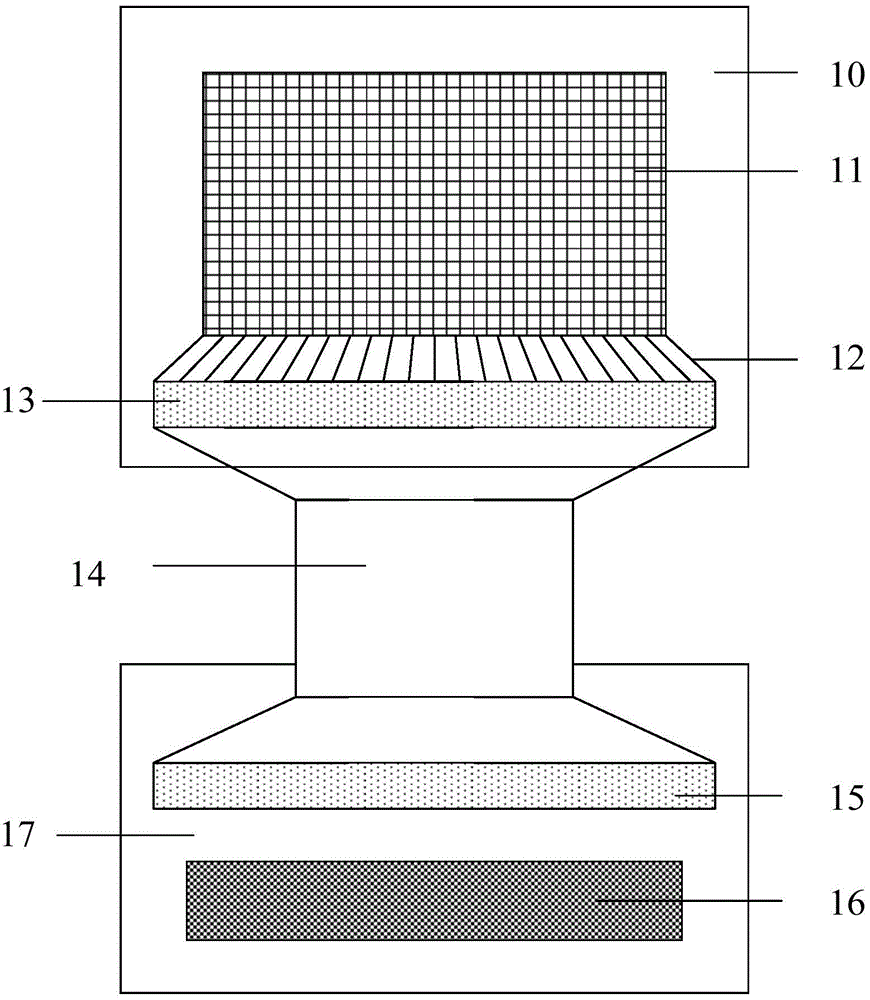

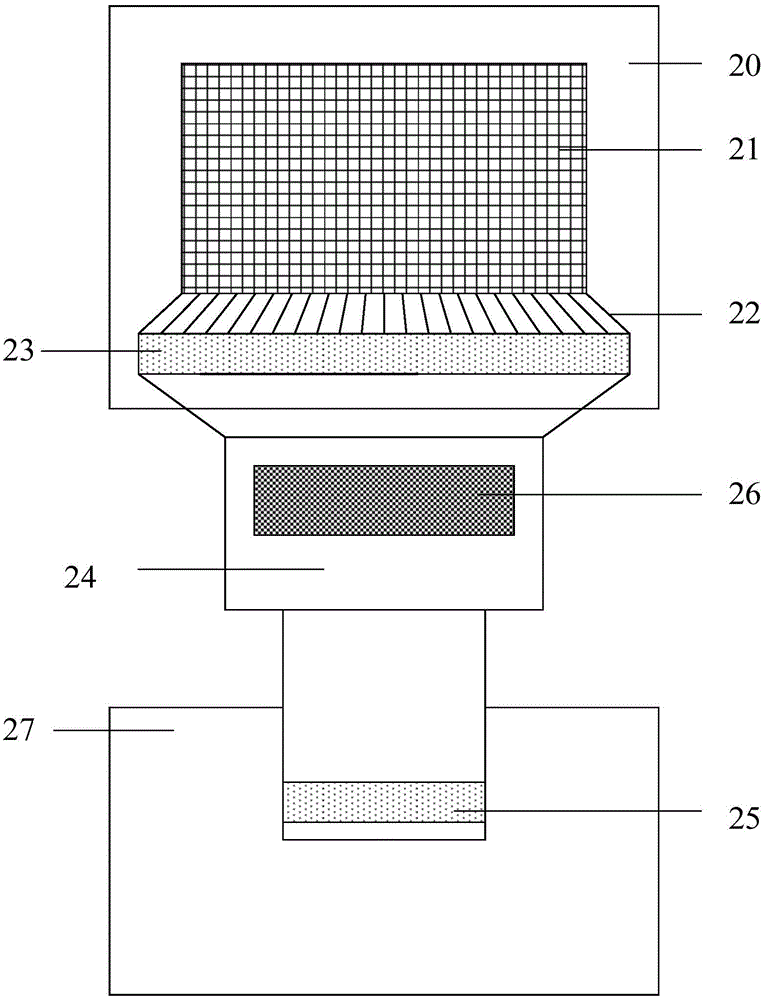

[0043] In order to solve the above technical problems, the present invention provides a fingerprint sensor, comprising:

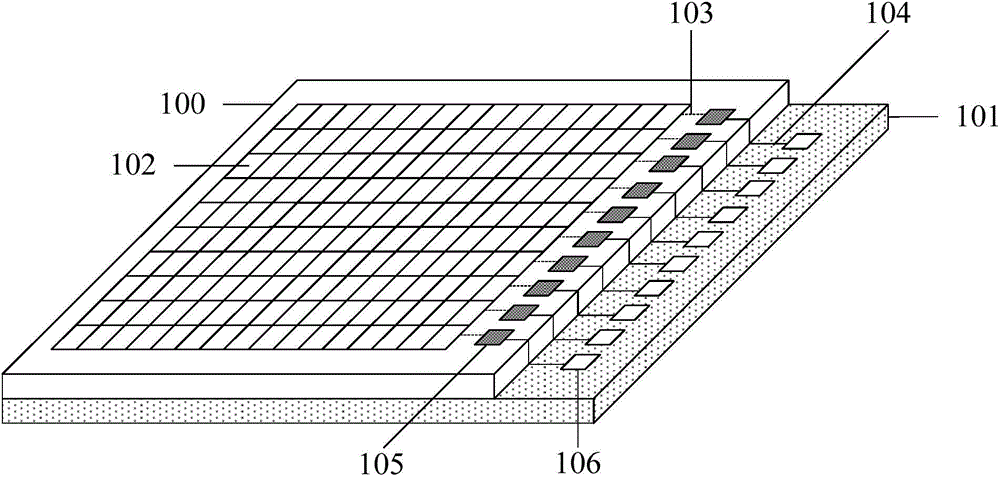

[0044] Substrate;

[0045] Pixel units arranged in an array on the substrate are used to collect fingerprint signals;

[0046] The signal line on the substrate is used to transmit the fingerprint signal collected by the pixel unit;

[0047] A plurality of exposed substrate binding pads on the substrate are correspondingly connected to the signal lines;

[0048] A printed circuit board located under the substrate for connection to other systems;

[0049] Multiple exposed circuit board bond pads located on the printed circuit board;

[0050] The binding wires connecting the substrate bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com