Shockproof capacitor

A technology of capacitors and capacitor cores, applied in capacitors, electrical components, etc., can solve problems such as reducing the service life of capacitors, increasing production costs, and expansion of metal shells, and achieves good overall insulation performance, high temperature resistance, and sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

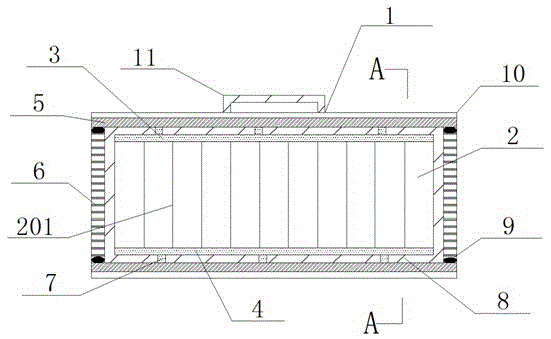

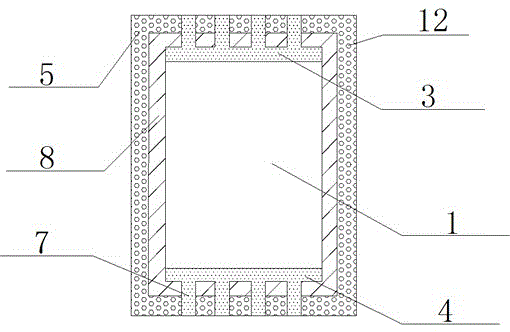

[0016] Such as figure 1 and figure 2 The shockproof capacitor shown includes a capacitor body 14, a capacitor core module 2, an upper plate 3 and a lower plate 4. The capacitor body 1 is a hollow structure, and a capacitor core composed of a capacitor core unit 201 is installed in the hollow part. Sub-module 2, the upper part of the capacitor core module 2 is connected to the upper plate 3, the lower part of the capacitor core module 2 is connected to the lower plate 4, and the upper and lower plates 3 and 4 are respectively provided with at least one heat exhaust groove 7 connected to the frame body 5, Both ends of the frame body 5 are provided with sealing covers 6 .

[0017] Among them, the capacitor core module 2 and the frame body 5 are arranged at intervals, and the space between them is filled with an insulating layer a8. An insulating layer b10 is also provided on the outer layer of the frame body 5, and an insulating carrying part 11 is installed on the insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com