Flexible package battery module

A soft-pack battery and module technology, applied in battery pack components, circuits, electrical components, etc., can solve the problem of reducing the energy density of soft-pack power battery packs, prone to scratches, pits, creases, and inability to reflect Advantages and other issues, to achieve the effects of high integration accuracy and efficiency, light weight, guaranteed reliability and vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

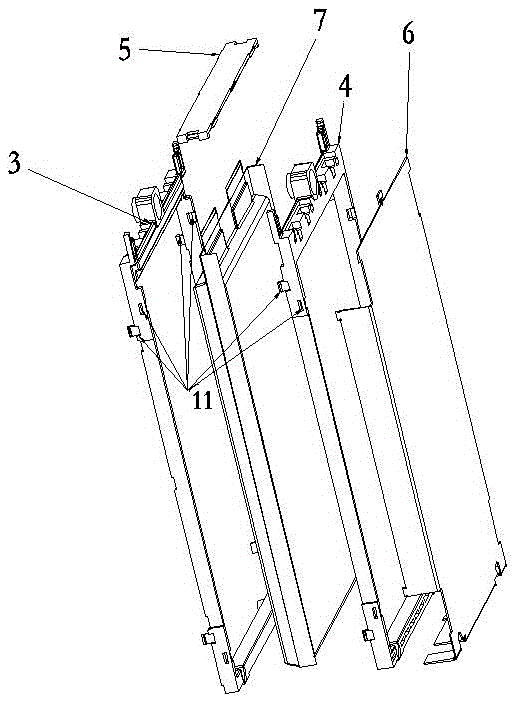

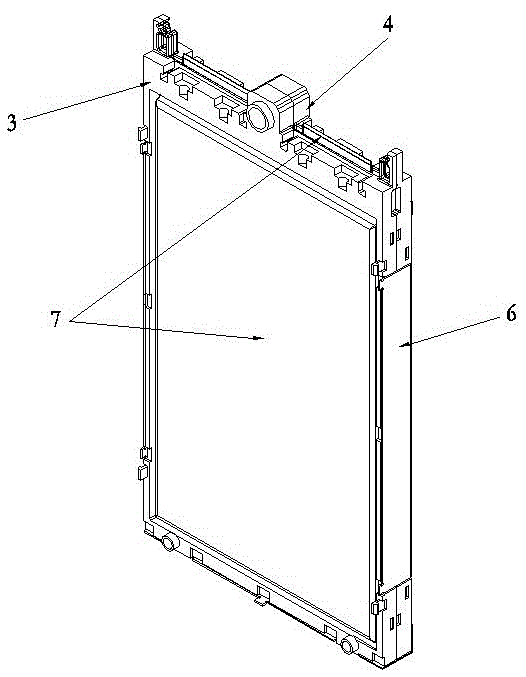

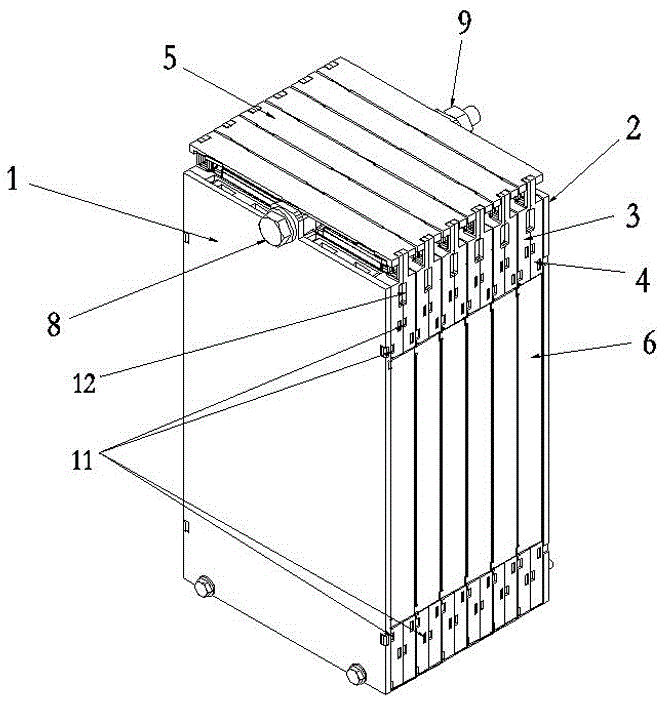

[0018] Such as Figure 1 to Figure 9 shown. The present invention comprises plastic side plate one 1, plastic side plate two 2, plastic left fixing frame 3, plastic right fixing frame 4, top cover 5, aluminum sheet 6, soft package electric core 7, screw rod 8, nut 9 and metal clamp 10.

[0019] Among them, the soft-packed battery cell 7 has positive and negative pole tabs, and the two sides of the soft-packed battery cell 7 are respectively provided with a plastic left fixing frame 3 and a plastic right fixing frame 4. Aluminum sheet 6, the two sides and the bottom of aluminum sheet 6 are provided with the flanging that can contact with plastic left holder 3 and plastic right holder 4. There are bolt holes and hole seats in the middle of the upper part of the plastic left fixing frame 3 and the plastic right fixing frame 4, and two bolt holes are symmetrically arranged in the lower part, the upper and lower sides of the two sides are provided with buckles that are interlocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com