Special machine for white celery

A special-purpose machine and soil-retaining technology, applied in the field of agricultural machinery and equipment, can solve the problems of difficult working environment, high labor intensity, low efficiency, etc., and achieve the effects of good overall machine stability, reduced labor intensity, and convenient soil extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

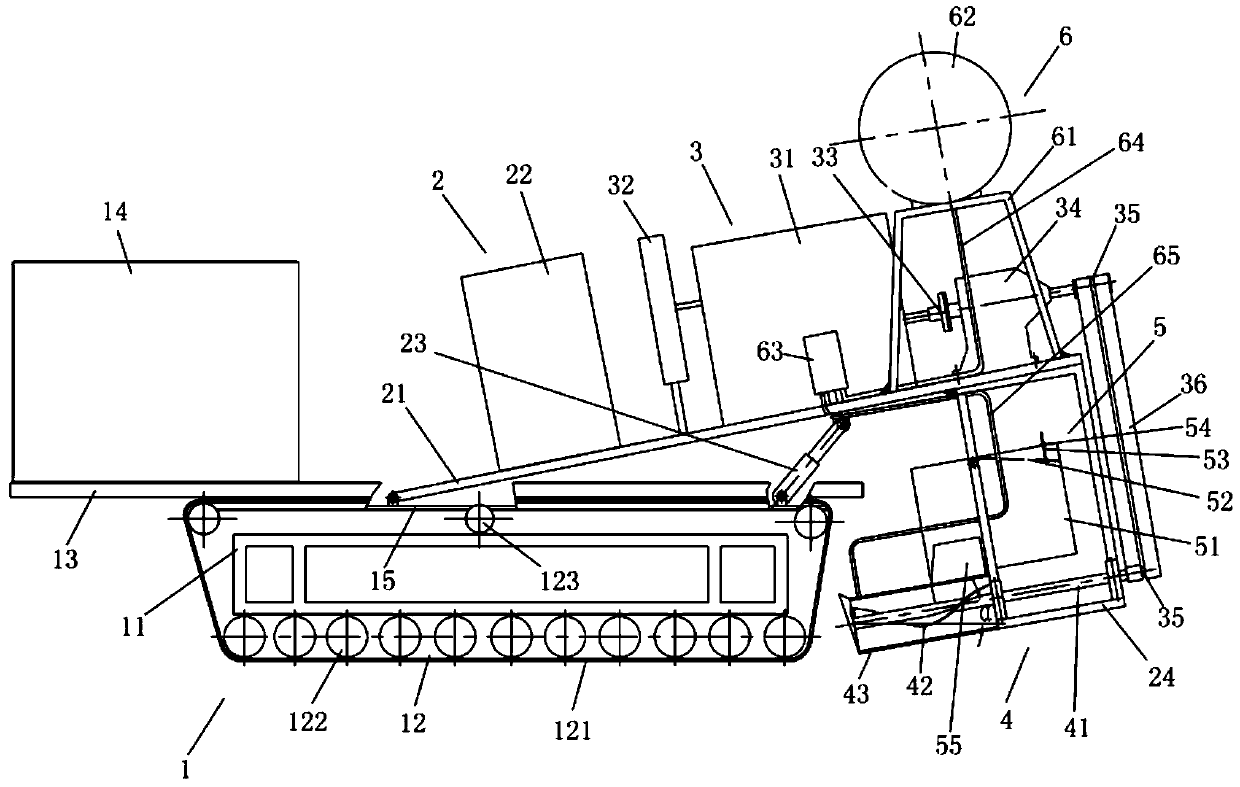

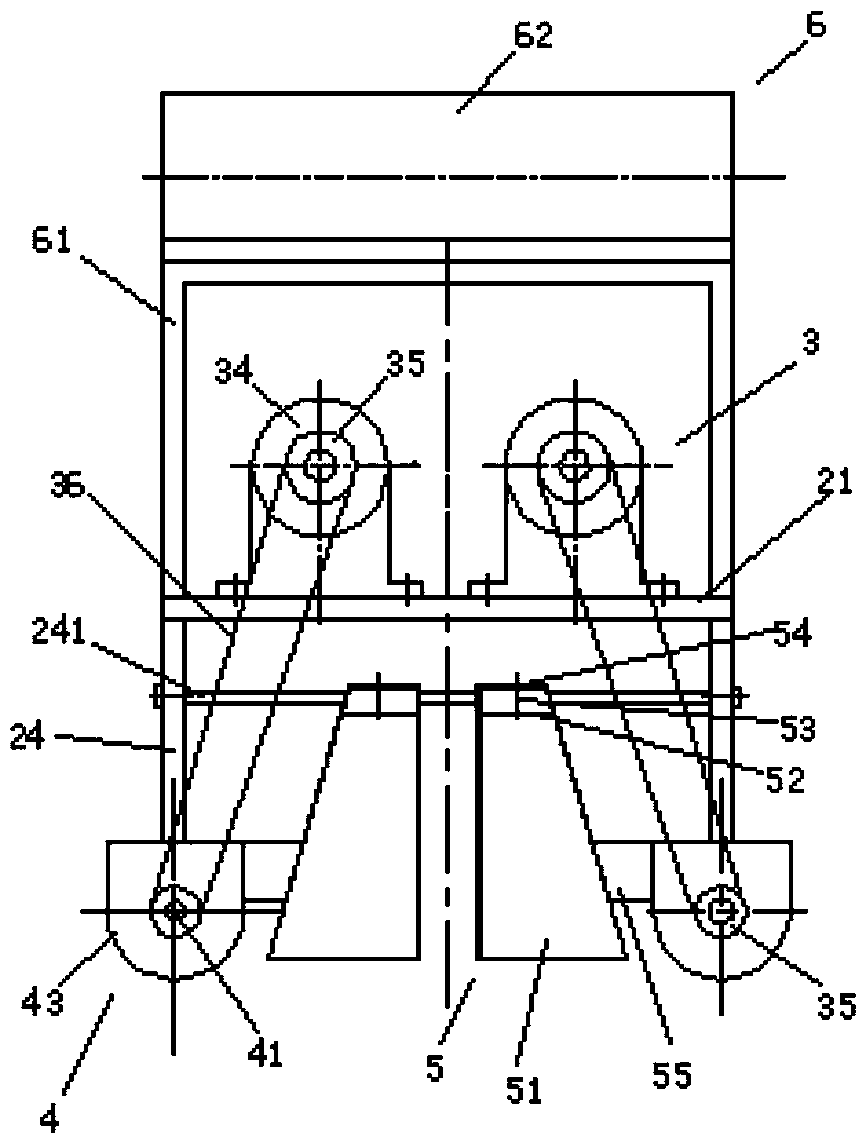

[0016] like figure 1 and figure 2 As shown, the present invention includes a machine body 1, a hydraulic control mechanism 2, a screw soil-taking driving mechanism 3, two screw soil-taking feeding mechanisms 4, and two back-up soil forming mechanisms 5. The body 1 comprises a frame 11, a crawler belt traveling mechanism 12 positioned at both sides of the frame 11, a mounting frame 13 and a first diesel engine 14, the mounting frame 13 is fixed on the upper side of the frame 11, and the first diesel engine 14 is fixed on the mounting frame by fasteners. On the frame 13 left ends. The crawler traveling mechanism 12 comprises an annular crawler belt 121, 11 traveling wheels 122 and a driving wheel 123, and the eleven traveling wheels 122 are hinged side by side on the lower side of the frame 11, the driving wheel 123 is hinged on the upper side of the frame 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com