Anti-displacement cold stamping drawing mold

A drawing die and cold stamping technology, which is applied in the field of anti-tampering cold stamping drawing dies, can solve the problems of limited anti-tampering ability, no convenient positioning structure, insufficient stability of the working process, etc., and achieve the effect of maintaining smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

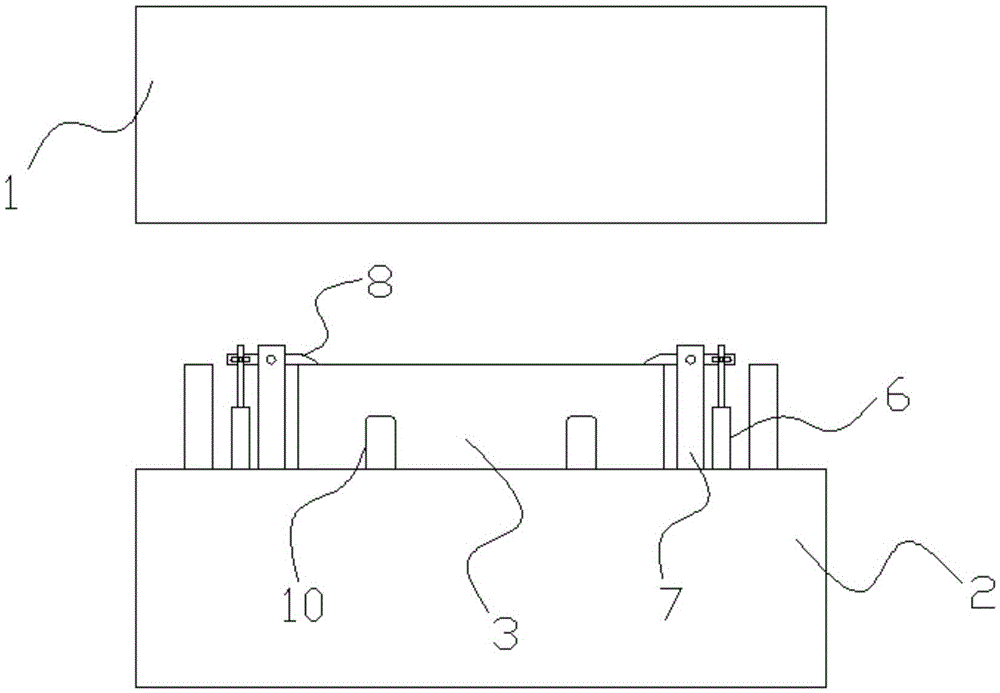

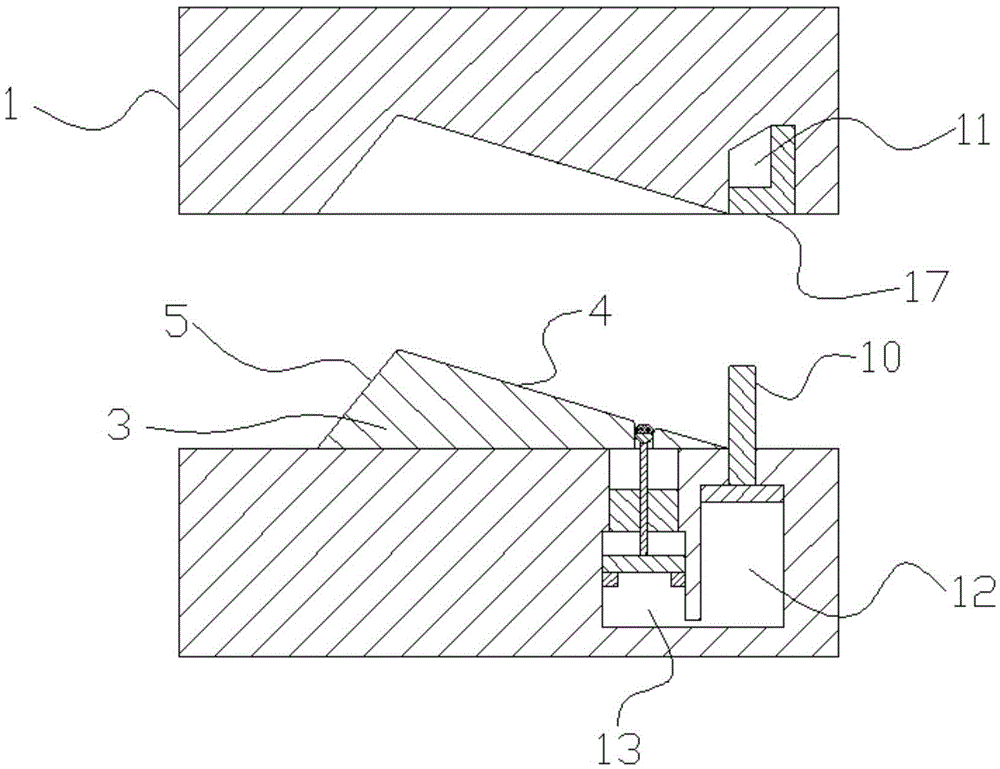

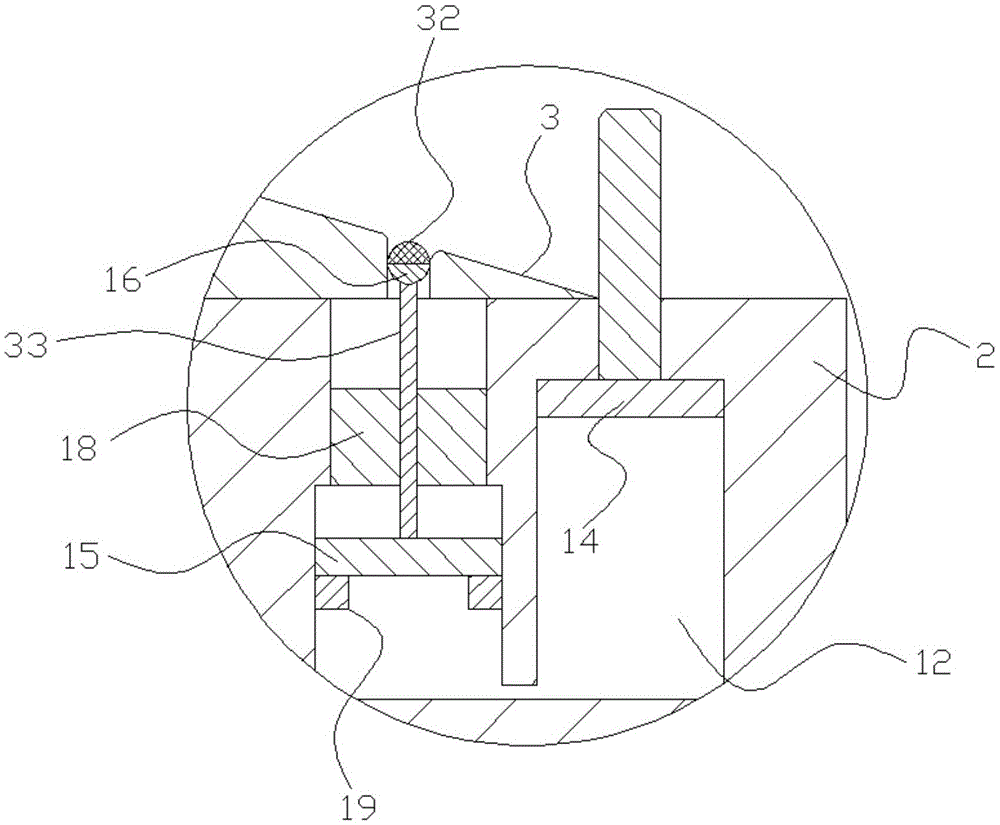

[0022] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 In the illustrated embodiment, a tamper-proof cold stamping drawing die includes a die 1 above and a punch 2 below, and the die includes a table 3, and the table has Long inclined profile 4, short inclined profile 5, the junction of the long inclined profile and the short inclined profile is the top section, the punch is provided with a plate cavity, the punch, the die After closing the mold, the remaining space left in the concave cavity of the plate is the mold cavity. The concave mold is provided with several pre-limiting parts, and the pre-limiting parts include a pre-limiting cylinder 6 and a positioning frame 7. , the piston rod of the pre-limiting cylinder faces upwards, and the positioning frame is provided with a bezel 8 whose middle part is rotatably connected with the locating frame. A horizontal sliding hole is provided, and the horizontal sliding hole 31 is provided with a rotating shaft 9. Th...

Embodiment 2

[0025] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 5 As shown in , the plate retaining column is provided with a plate hole 20, a plate 21 passes through the plate hole, one end of the plate is provided with a plate pressure head 22 for pressing the plate, and the other end is connected to One end of a high-elastic extension spring 23, the lower surface of the described pressing plate is provided with an anti-pullback protrusion 24, and the described punch is provided with a limit slide block 25 and a slide block groove 26. The slider can slide up and down in the slider groove, and the slider groove is provided with some top block springs 27 for resisting the limit slider, and the limit slider is provided with a through hole 28, and The anti-pullback limiting groove corresponding to the anti-pullback protrusion, the anti-pullback limiting groove is located below the passing hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com