A battery pressing fixture

A technology for pressing jigs and batteries, used in manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as operator injury, no protection measures, pressure explosion of batteries, etc., to achieve protection safety, high degree of automation, The effect of high pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

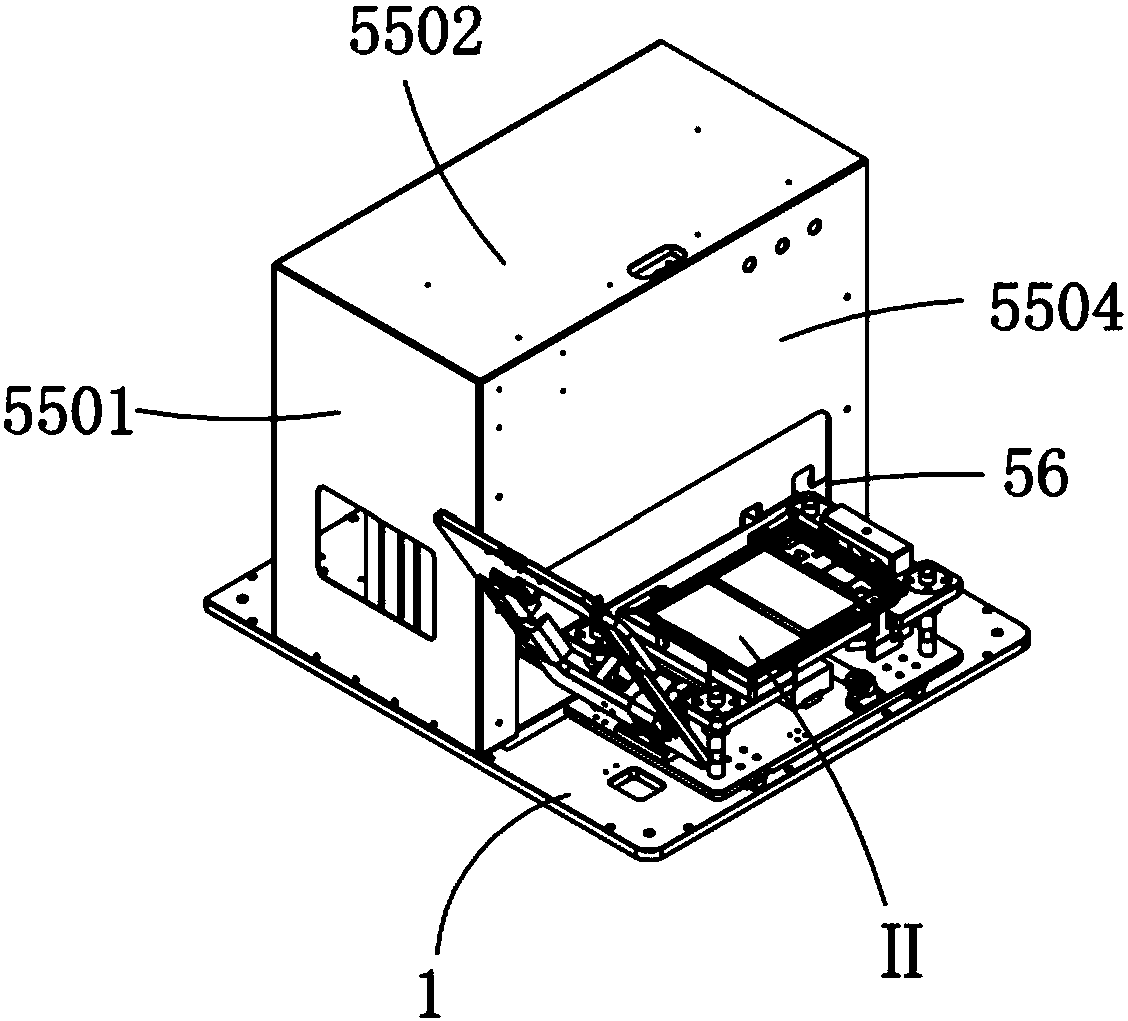

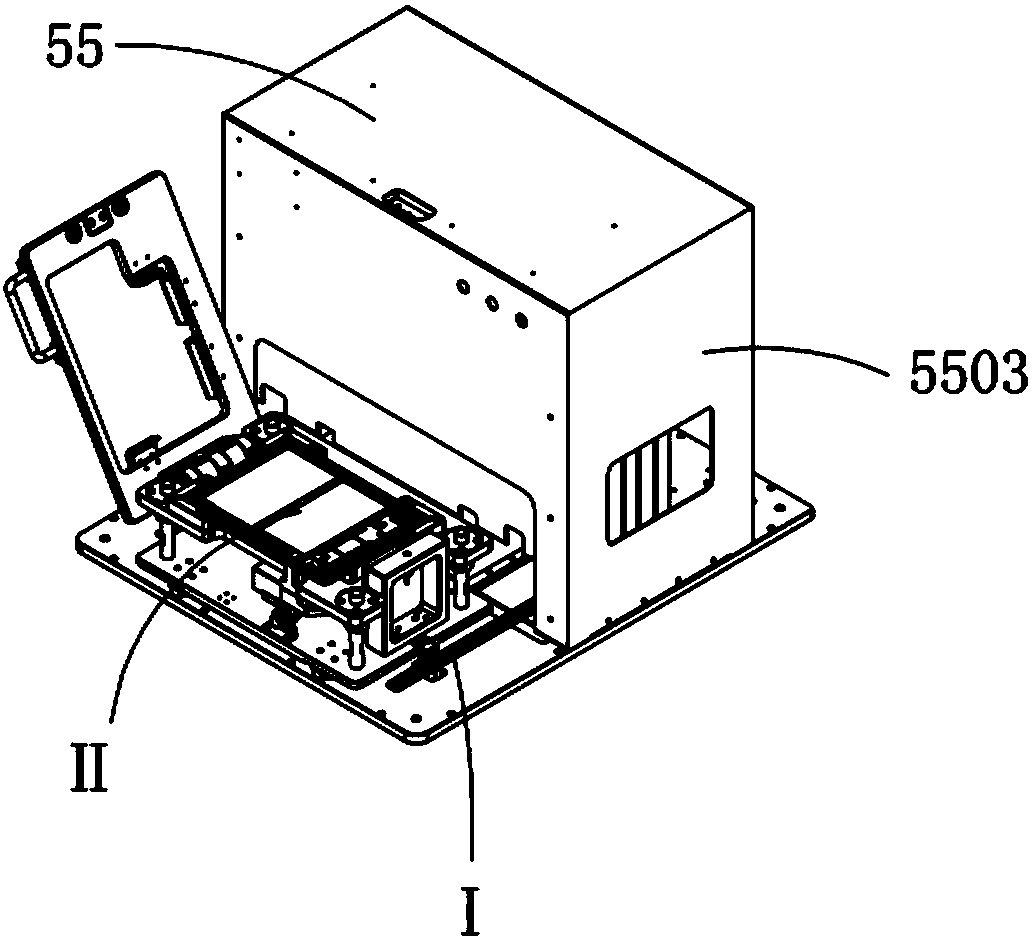

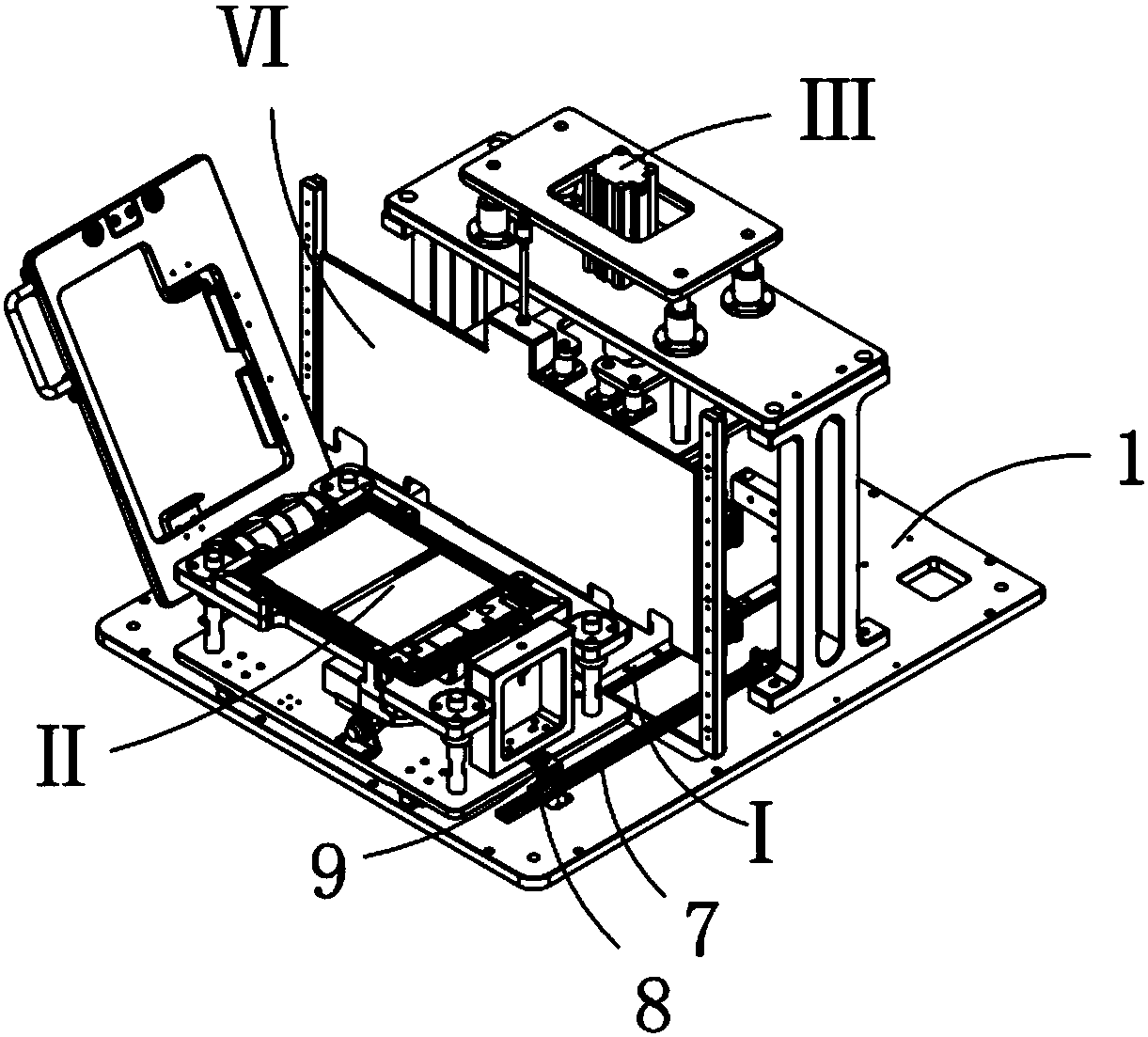

[0041] Examples, see attached Figure 1-17, a battery pressing fixture, including a base plate 1, a transfer mechanism I is installed on the base plate, and a lifting carrier II for positioning the bottom case of an electronic product and the position of the battery is installed on the transfer mechanism; the base plate A battery pressing mechanism III for pressing the battery onto the bottom case of the electronic product and maintaining the pressure for a period of time is installed on the top; the transfer mechanism can drive the lifting carrier to move directly under the battery pressing mechanism.

[0042] The transfer mechanism includes a rodless cylinder 2, a cylinder bracket 3, a transfer connection block 4, a transfer slider 5, a transfer slide rail 6, a transfer installation bar 7, a transfer photoelectric sensor 8, and a transfer induction sheet 9 , limit block a10 and limit block b11, the rodless cylinder is installed on the lower part of the base plate through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com