Installation device for long shaft of ventilating nozzle

A technology for installing devices and ventilating nozzles, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of poor product quality, difficult to control the included angle, and high scrap rate, so as to reduce production costs, easy to control the included angle, and reduce the scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

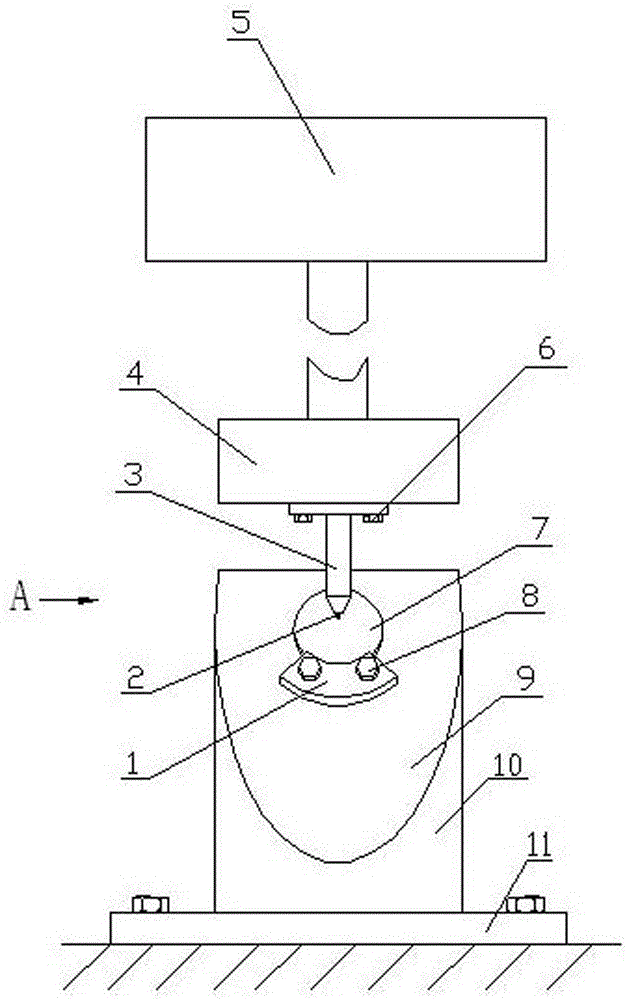

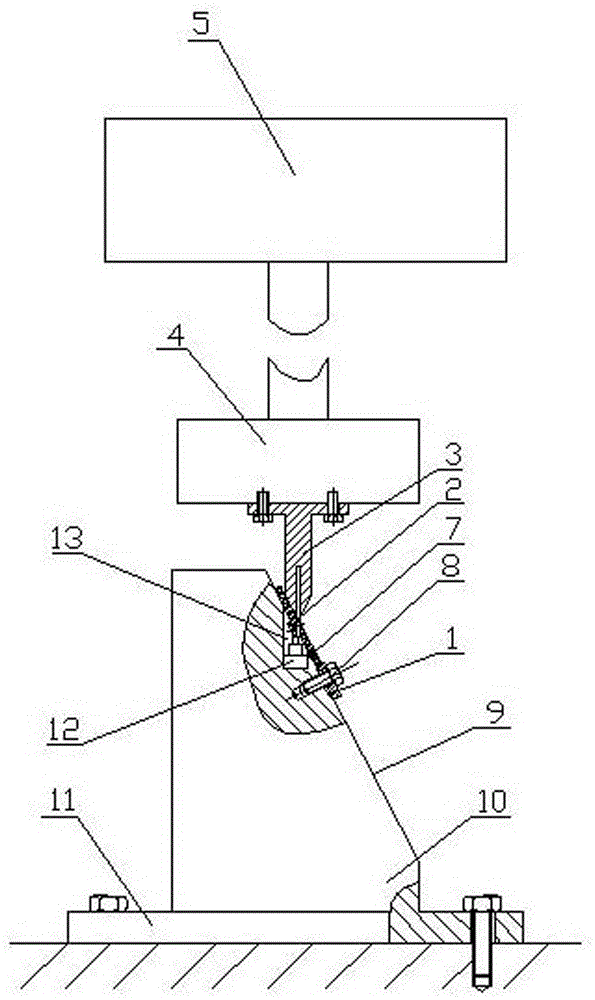

[0013] Such as figure 1 and figure 2 As shown, the installation device for the long axis of the air nozzle of the present invention includes a base 10, the base 10 is cylindrical, and a workbench 11 is fixed at its lower end. The upper side of the base 10 is processed with a beveled surface 9, and the beveled surface 9 is aligned with the vertical The included angle of the line is equal to the included angle between the long axis 2 of the ventilation nozzle and the cover surface of the ventilation cover 7 . An upper vertical blind hole 13 is processed on the beveled surface 9 , and a limit block 12 is fixed on the bottom of the upper vertical blind hole 13 . On the chamfered surface 9 below the opening of the upper vertical blind hole 13, a bracket 1 for supporting the ventilation cover 7 is arranged. An indenter 4 is arranged on the top of the base 10 , and a hydraulic press 5 is arranged above the indenter 4 . A push rod 3 is fixed below the pressure head 4 by means of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com