Automobile plate spring guide arm

A technology of automobile plate and guide arm, which is applied in the field of automobile parts, can solve problems such as unsatisfactory stress conditions, enlarged brackets, and increased manufacturing costs, so as to solve the problems of design height and horizontal layout space, optimize the structure, reduce Effect of Part Quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

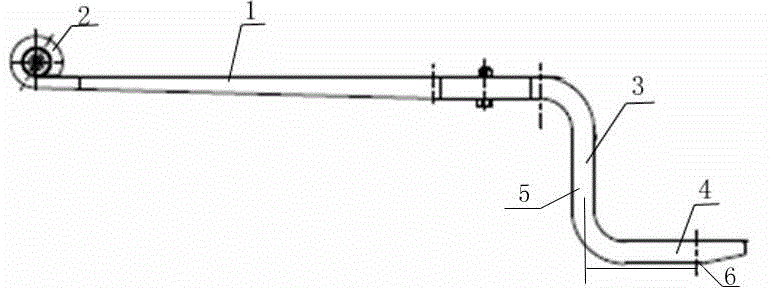

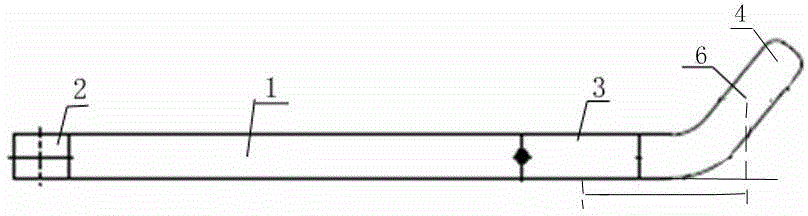

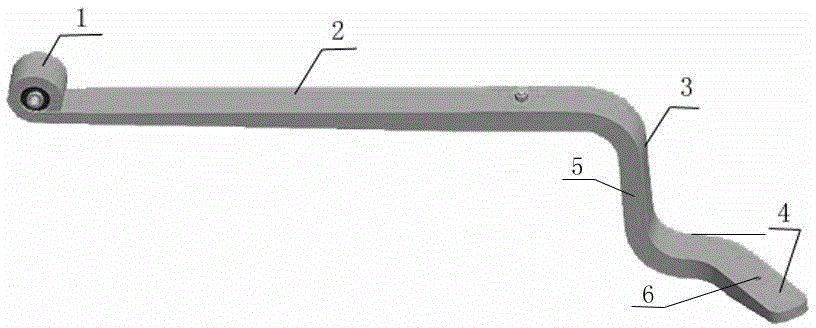

[0023] The invention is like figure 1 , 2 , 3 and 4.

[0024] The automobile leaf spring guide arm includes a straight leaf spring 1. A curling lug 2 is provided on one end of the straight leaf spring 1, and a "Z" leaf spring 3 is provided on the other end of the straight leaf spring 1. , A side edge 4 is bent to the side at the bottom edge of the "Z"-shaped leaf spring 3.

[0025] The side edges 4 are respectively arranged on both sides of the bottom edge of the "Z"-shaped leaf spring, which is suitable for the symmetrical arrangement of automobile plate yellows, and ensures the symmetry of the two sides of the automobile.

[0026] The support arm 5 and the flat plate spring 1 form a vertical angle with the bottom edge of the "Z"-shaped plate spring.

[0027] The side 4 and the bottom side of the "Z" leaf spring respectively form an included angle of 30-50°, and the distance between the airbag installation center position 6 on the side 4 and the center of the support arm 5 is not mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com