Automatic tipping and guiding mechanism of ceramic clay storage barrel

A guide mechanism and a technology for placing barrels, which is applied in liquid handling, emptying containers, loading/unloading, etc., can solve problems such as low efficiency and troublesome handling, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

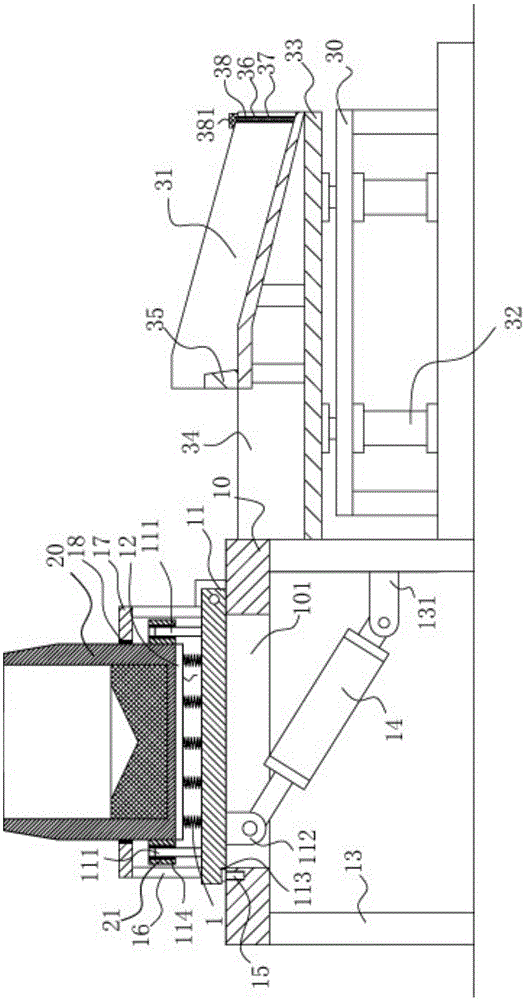

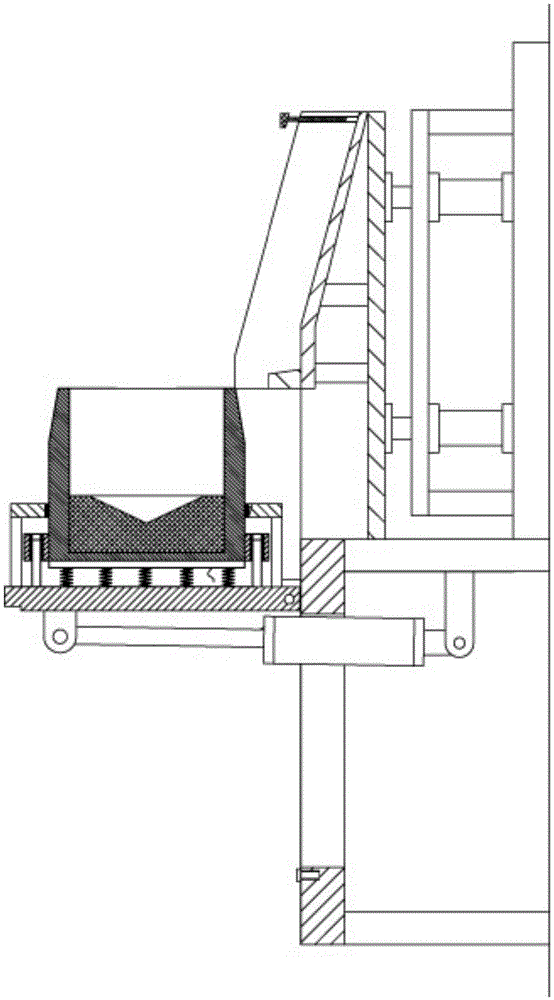

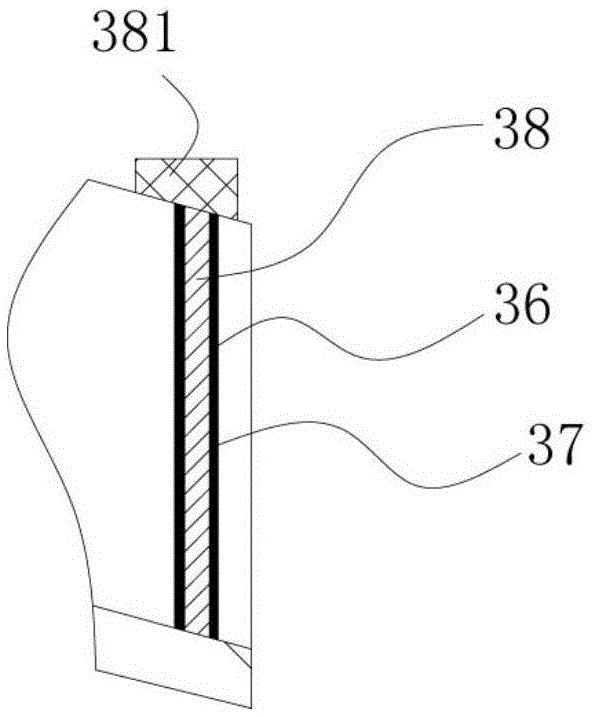

[0018] Example: see Figure 1 to Figure 3 Shown, a kind of automatic dumping guide mechanism for pottery with clay placed bucket body, comprises frame body 10 and guide frame 30, and the top plate of described frame body 10 is placed with turning plate 11, and the right end of turning plate 11 is hinged on the frame body 10 On the top surface of the right end place, the turnover plate 11 is provided with an electromagnet block 12, and the top surface of the electromagnet block 12 is placed with clay to place the staving 20, and the guide frame 30 is at the right side of the frame body 10, and the guide frame 30 is provided with There is an oblique guide chute body 31, the left end of the oblique guide chute body 31 is higher than the right end, and the left end of the oblique guide chute body 31 corresponds to the clay placement barrel 20;

[0019] The top plate of the frame body 10 below the flip plate 11 has a through groove 101, the left end bottom surface of the flip plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com