Crane device with three-degree-of-freedom active heave compensation function and compensation method

A technology of wave compensation and degree of freedom, applied in the field of ships, can solve the problems of long servo cylinder, poor heave compensation effect, and reduced stability, and achieve the effects of wide compensation range, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

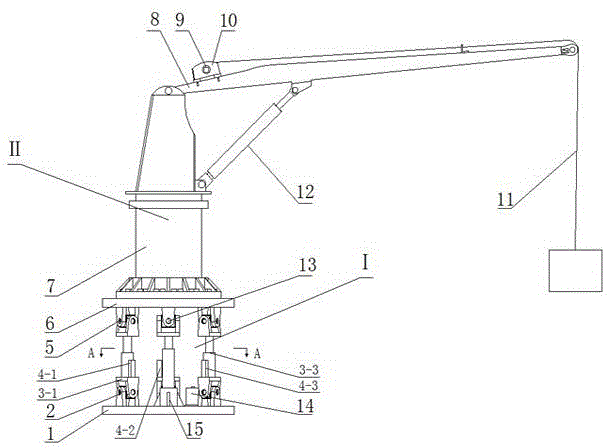

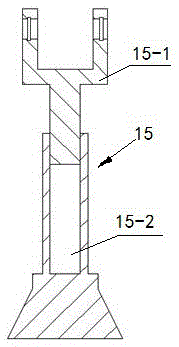

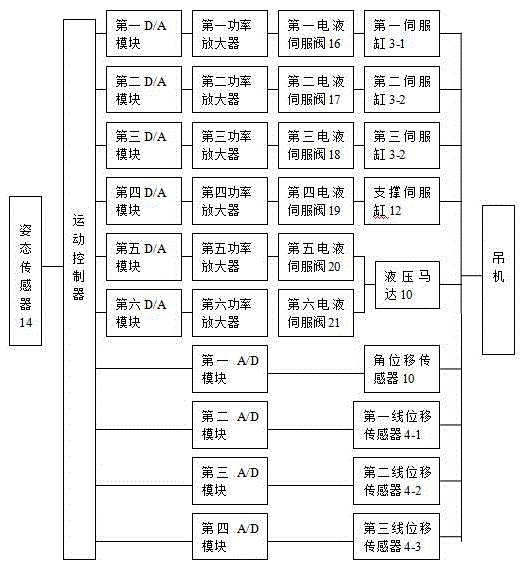

[0016] see figure 1 and figure 2 , the present invention comprises two parts, the stable platform I below and the crane II above. Among them, the bottom of the stable platform I is a circular static platform 1, the top is a circular dynamic platform 6, the circular dynamic platform 6 is directly above the circular static platform 1, and the circular static platform 1 and the circular dynamic platform 6 parallel to each other, and their central axes are collinear. The circular static platform 1 is fixed on the deck of the ship by bolts, and the circular dynamic platform 6 is connected with the crane II by bolts. The bottom of the crane II is a column 7, and the circular moving platform 6 and the column 7 are fixedly connected by bolts, and the central axes of the circular moving platform 6 and the column 7 must be kept in line during installation. The upper end of the column 7 is connected with the rotating end of the boom 8 through a pin shaft, and the support servo cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com