Aqueous flame-retardant rubber asphalt coating film waterproof material and preparation and construction method thereof

A technology of rubber asphalt and waterproof materials, applied in the field of materials, can solve the problems of physical strength and thermal properties that need to be improved, and achieve the effect of weak durability, high physical strength and poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

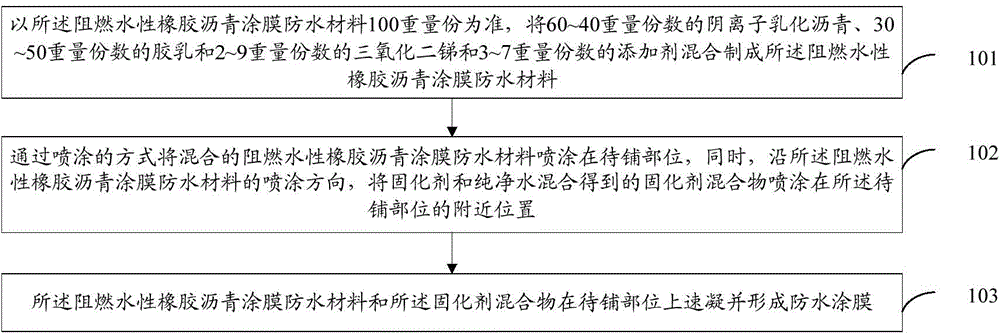

Method used

Image

Examples

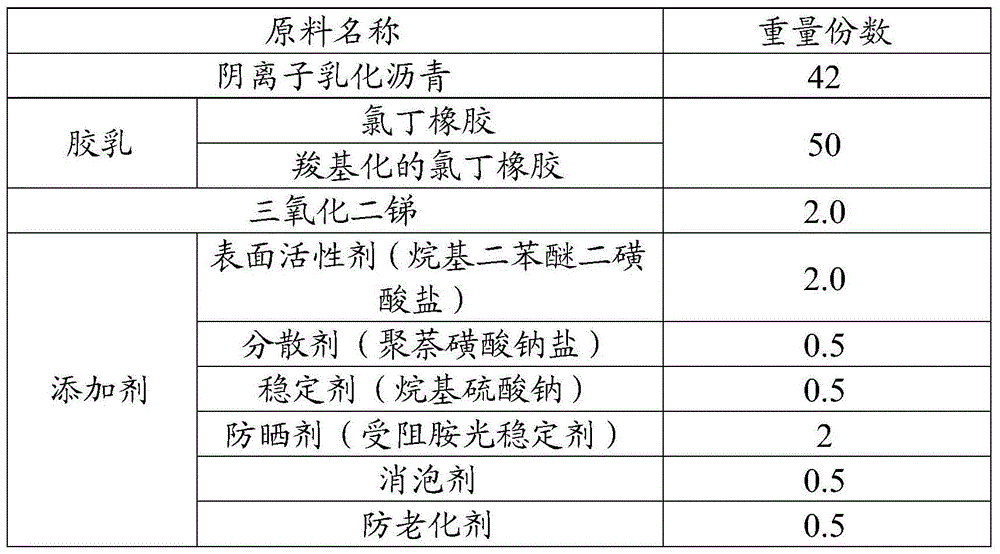

Embodiment 1

[0066] Prepare 100 parts by weight of the electrically insulating water-based rubber asphalt coating film waterproof material, and the proportion of each component is as follows:

[0067]

[0068] Table 1

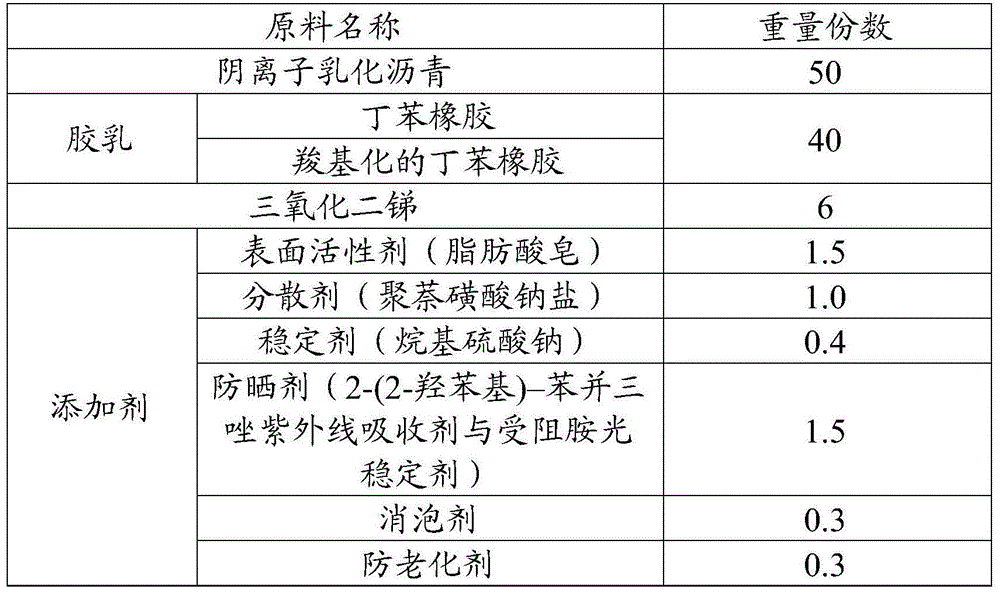

Embodiment 2

[0070] Prepare 100 parts by weight of the electrically insulating water-based rubber asphalt coating film waterproof material, and the proportion of each component is as follows:

[0071]

[0072] Table 2

Embodiment 3

[0074] Prepare 100 parts by weight of the electrically insulating water-based rubber asphalt coating film waterproof material, and the proportion of each component is as follows:

[0075]

[0076] table 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com