A kind of preparation method of y3al5o12 coating applied to aluminum-based substrate

A y3al5o12 coating technology, which is applied in metal material coating process, coating, fusion spraying, etc., can solve problems such as cracks between coating and substrate, large difference in thermal expansion coefficient, and coating peeling, so as to relieve interface stress , Good transition effect, increase the effect of interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

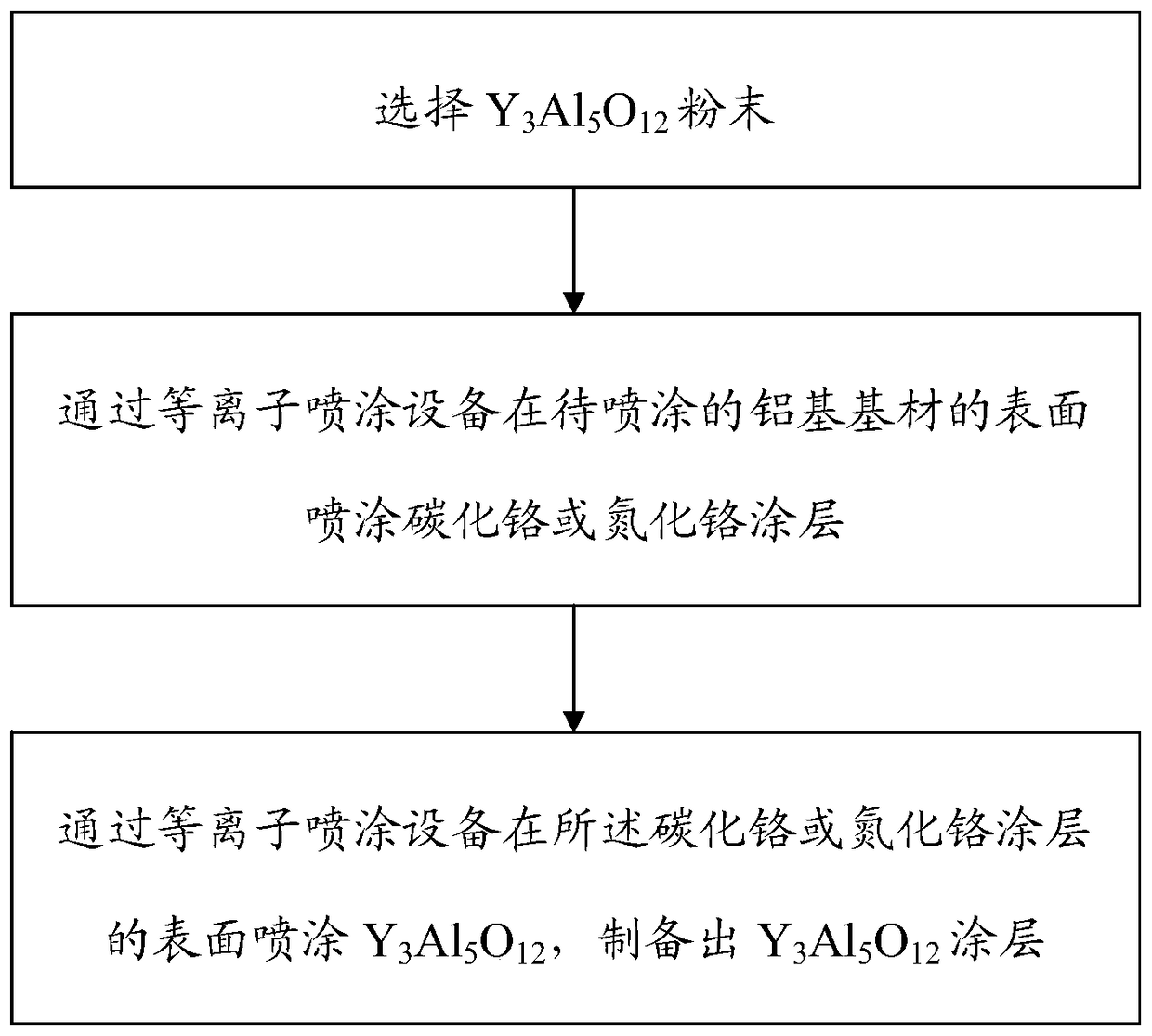

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a Y 3 Al 5 o 12 The preparation method of coating, comprises the steps:

[0028] Step 110: Choose Y 3 Al 5 o 12 powder;

[0029] Specifically, choose Y 3 Al 5 o 12 The particle size of the powder ranges from 10 to 80 μm, and it has a spherical porous structure. It is a hollow micron ball composed of small nano-sized particles and has excellent fluidity.

[0030] Step 120: spraying a chromium carbide or chromium nitride coating on the surface of the aluminum-based substrate to be sprayed by plasma spraying equipment;

[0031] Specifically, the ion gases used by the plasma spraying equipment are Ar and H 2 , the flow rate of Ar gas is 40~100L / min, H 2 The gas flow rate is 5-20L / min; the arc voltage of the plasma spraying equipment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com