Graphene 3D printing material and preparation method thereof

A 3D printing and graphene technology, applied in the field of 3D printing materials, can solve the problems of inconsistent phases of 3D printing products, affecting product uniformity and stability, and products are prone to cracks, etc., achieving excellent performance stability, easy control, and improved molding The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

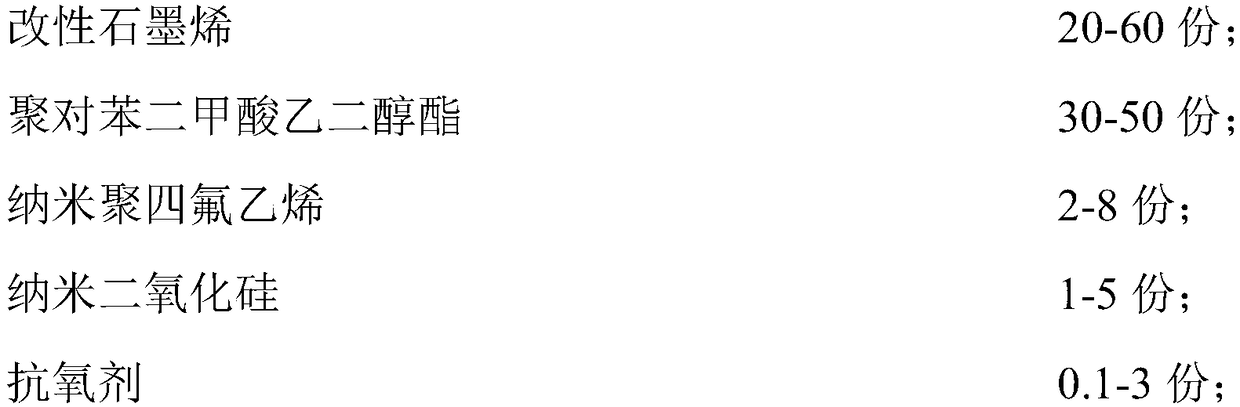

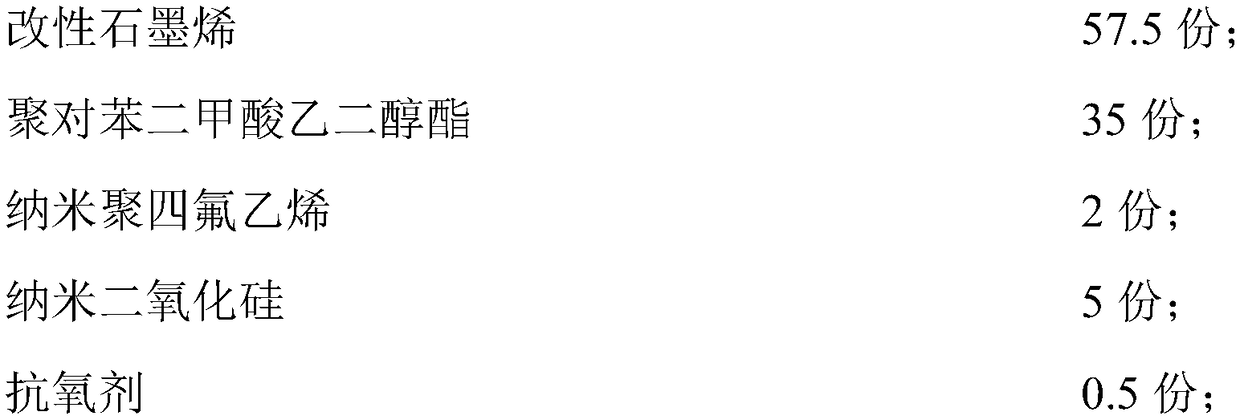

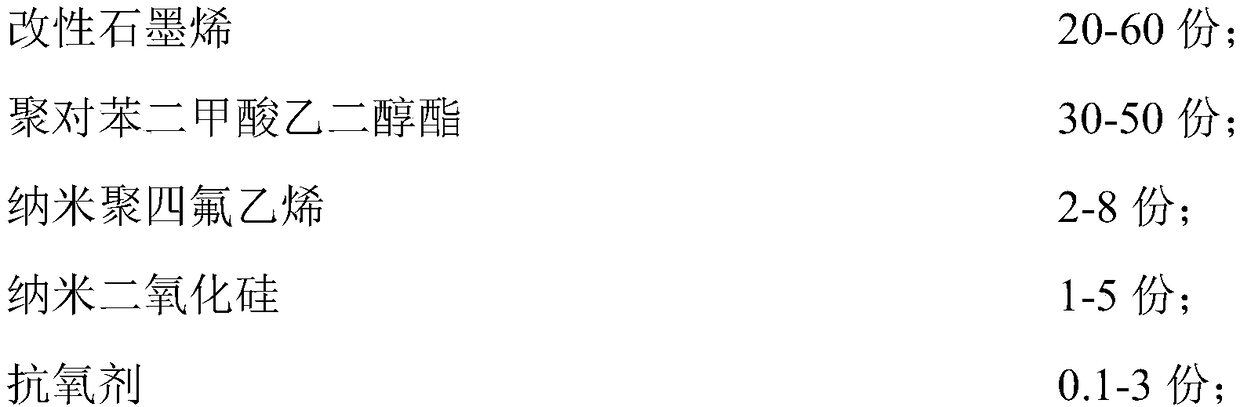

[0027] An embodiment of the present invention provides a graphene 3D printing material, comprising the following components in the following parts by weight:

[0028]

[0029] Described modified graphene is made of graphene oxide, ammoniacal liquor, polyethylene glycol diglycidyl ether, wherein, the mass ratio of described graphene oxide and described polyethylene glycol diglycidyl ether is 100:1- 5.

[0030] Specifically, in the embodiment of the present invention, the modified graphene, as the matrix material of the graphene 3D printing material, has excellent mechanical propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com