Filling pumps for food filling

A technology for filling pumps and food, which is applied to the components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc. It can solve the problems of short life, poor high temperature resistance, etc., and achieve long service life, Avoid collision damage, high temperature resistance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

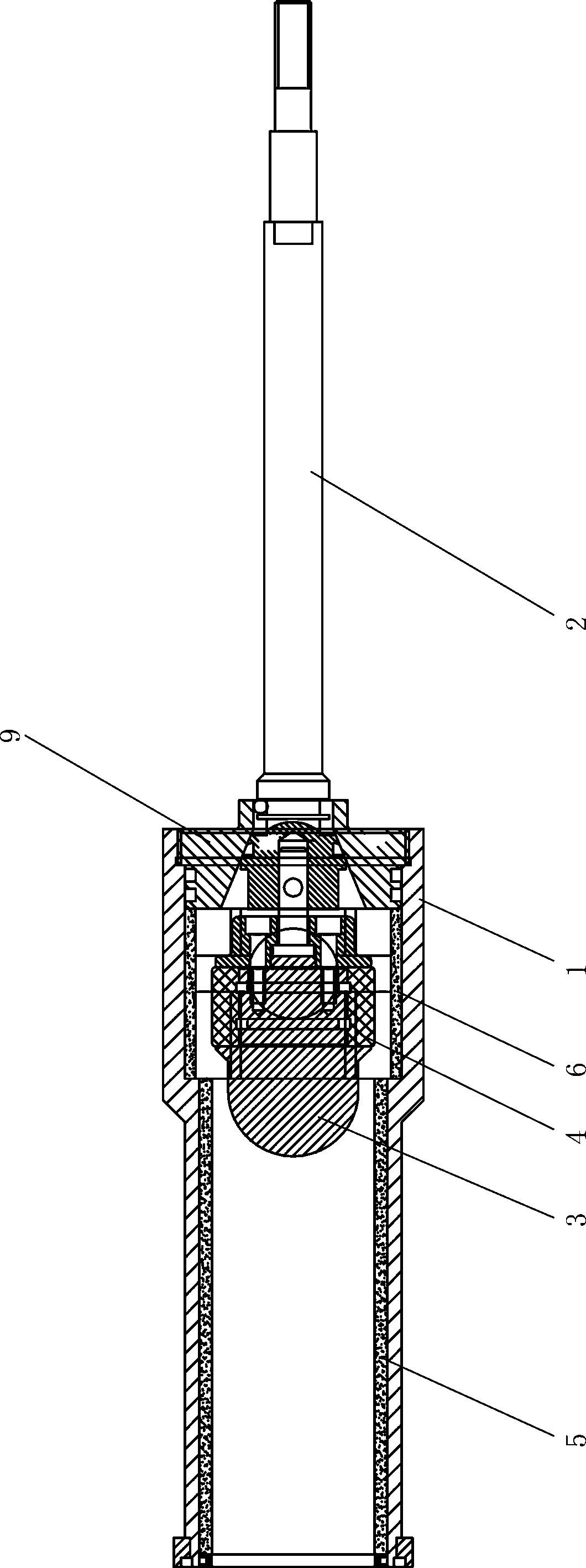

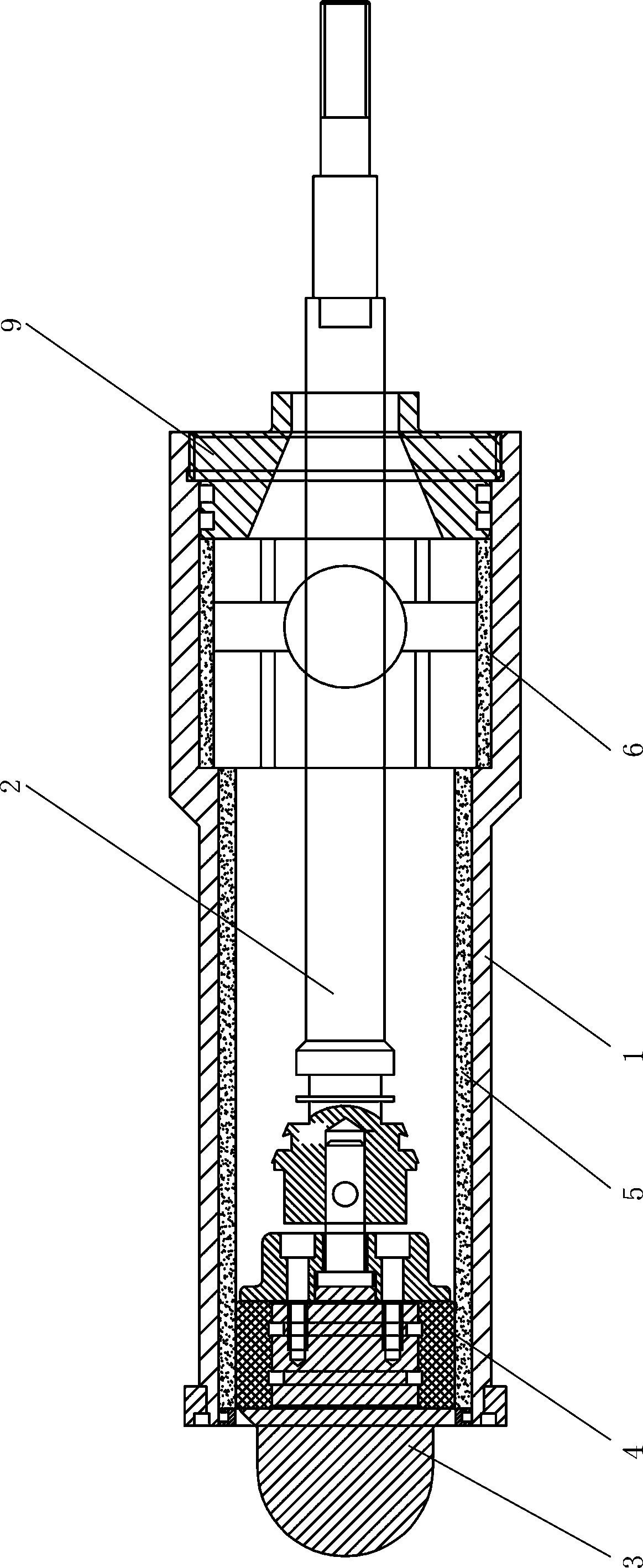

[0015] Such as Figure 1-3 As shown, the filling pump for food filling in this embodiment includes a pump body, a filling rod 2, and a filling head 3. The filling head 3 is installed at the bottom of the filling rod 2, and the inner cavity of the pump body is from top to bottom. The bottom is the cleaning cavity and the filling cavity in sequence, and the filling head 3 at the bottom of the filling rod 2 passes through the cleaning cavity and the filling cavity sequentially from top to bottom.

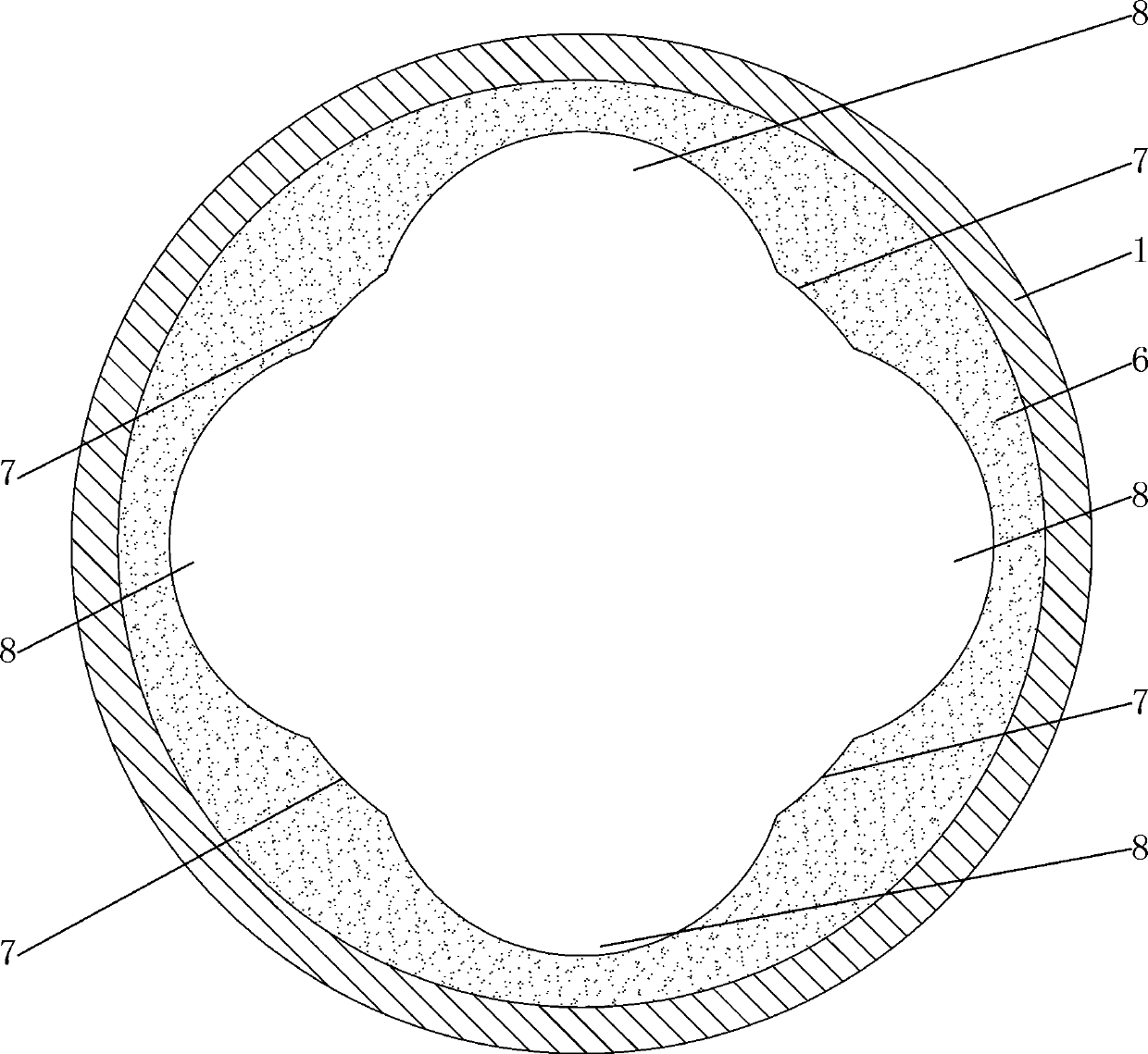

[0016] The pump body includes a stainless steel outer casing 1, and the stainless steel outer casing 1 is provided with a ceramic filling cavity inner sleeve 5, and the filling cavity is an inner cavity of the ceramic filling cavity inner sleeve 5, and the side wall of the filling head 3 is installed with a The ceramic sealing ring 4 matched with the inner wall of the inner sleeve 5 of the ceramic filling cavity.

[0017] The stainless steel jacket 1 is also provided with a ceramic cl...

Embodiment 2

[0022] The difference between the filling pump for food filling in this embodiment and Embodiment 1 is:

[0023] There is no ceramic cleaning chamber inner sleeve in the stainless steel jacket. The disadvantage of this solution is that after each cleaning, the filling head needs to be aligned when it returns to the inner sleeve of the ceramic filling cavity. The alignment step takes a lot of time and the action is slow. The ring and the inner sleeve of the ceramic filling chamber are easily damaged due to collision, and it is difficult to ensure the accuracy of filling, which affects the service life of the filling pump.

Embodiment 3

[0025] The difference between the filling pump for food filling in this embodiment and Embodiment 1 is:

[0026] The inner wall of the inner sleeve of the ceramic cleaning chamber has no positioning curved surface. The disadvantage of this solution is that after each cleaning, the filling head needs to be aligned when it returns to the inner sleeve of the ceramic filling cavity. The alignment step takes a lot of time and the action is slow. The sealing ring and the inner sleeve of the ceramic filling chamber are easily damaged due to collision, and it is difficult to ensure the accuracy of filling, which affects the service life of the filling pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com