A Top Entry Axial Flow Check Valve

A technology for check valves and valve seats, which is applied in the direction of control valves, valve devices, and functional valve types. flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

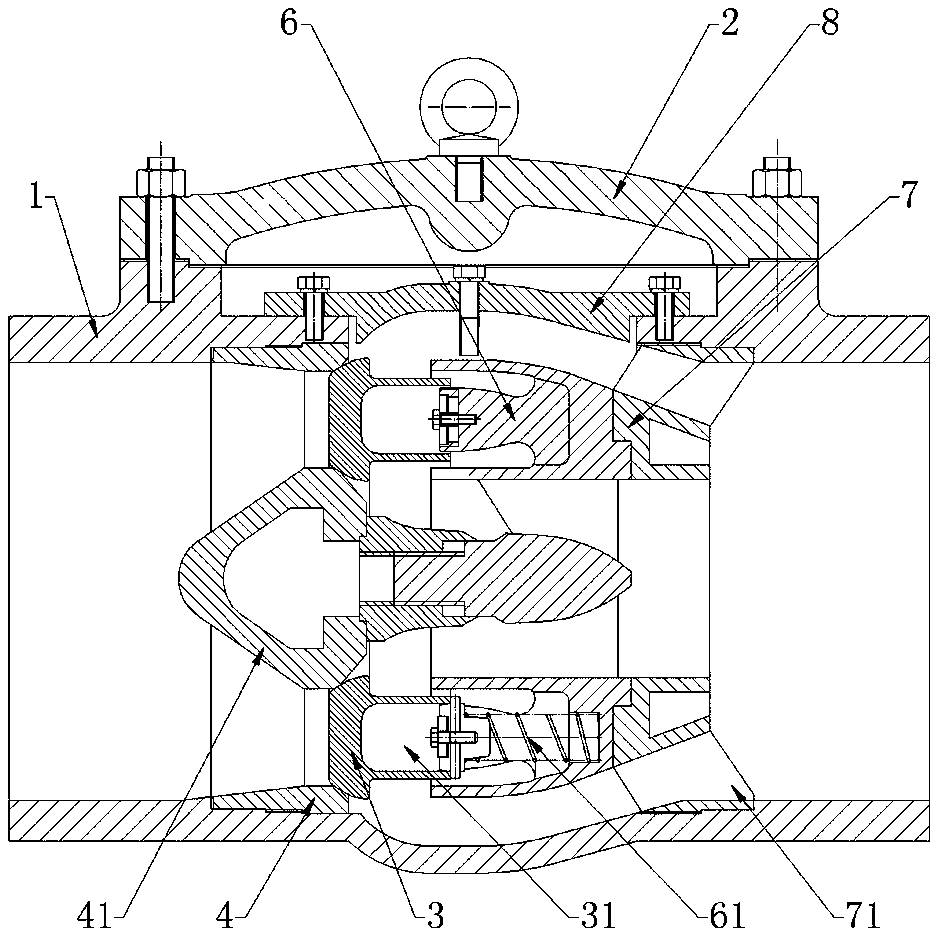

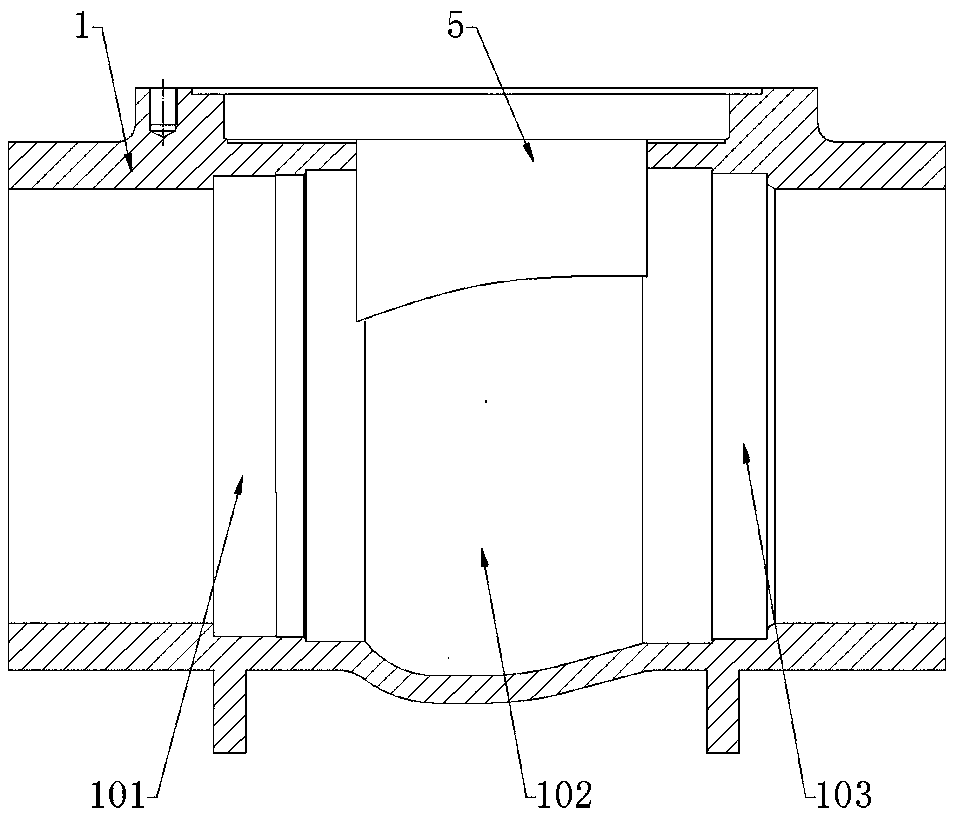

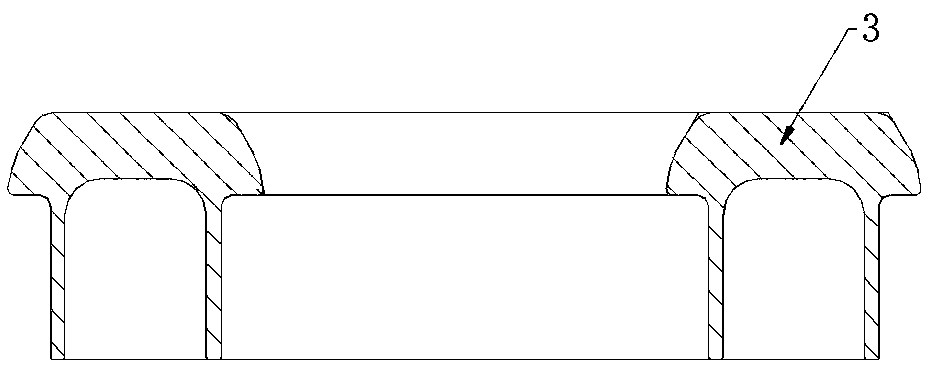

[0021] See figure 1 with figure 2 , Top-mounted axial flow check valve, including valve body 1, valve disc 3, valve seat 4 and valve cover 2. The valve body 1 is opened with a maintenance hole 5, and the maintenance hole 5 is covered with a valve cover 2; The internal distribution is a medium inlet 101, a valve cavity 102 and a medium outlet 103; a valve seat 4 is fixed at the medium inlet 101, and the valve seat 4 is a ring structure. The center of the valve seat 4 is provided with a valve seat guide 41, the valve seat The guide head 41 has a tapered structure; the valve seat 4 is softly connected to the valve disc 3 at the back of the medium inlet 101, that is, the valve disc 3 and the valve seat 4 are not in a fixed connection relationship. When the check valve is closed, the valve disc 3 and The valve seat 4 is connected in a sealed manner by the sealing surface between each other, and when the check valve is open, the valve disc 3 and the valve seat 4 are in a separated st...

Embodiment 2

[0024] See figure 1 This embodiment is an improvement of the first embodiment, that is, under the valve cover 2 and at the maintenance hole 5, a fairing 8 with a streamlined structure is provided, and the inner surface of the corresponding valve body 1 has a streamlined structure.

[0025] See Figure 4 , Due to the increase of the fairing, the flow of the medium is changed from turbulent flow to orderly flow, which can effectively reduce the generation of noise.

Embodiment approach 3

[0027] This embodiment is another improvement of the first embodiment. The fixed connection between the valve seat and the valve body is sealed by a two-way spring energy storage sealing ring.

[0028] The two-way spring energy storage sealing ring provides longitudinal sealing in the medium conveying direction (horizontal), and when the medium returns, it provides transverse sealing; thereby providing lasting elasticity, and at the same time, it can make up for the gap generated during low-temperature cold shrinkage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com