Same-floor rotational flow tee joint

A technology of three-way and three-way pipes, which is applied in the field of three-way pipes, can solve the problems of small bathroom headroom, heavy backfilling workload, and increased building load, etc., and achieve the effects of good ventilation capacity, improved drainage capacity, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The same-level combiner in this embodiment is connected to the standpipe.

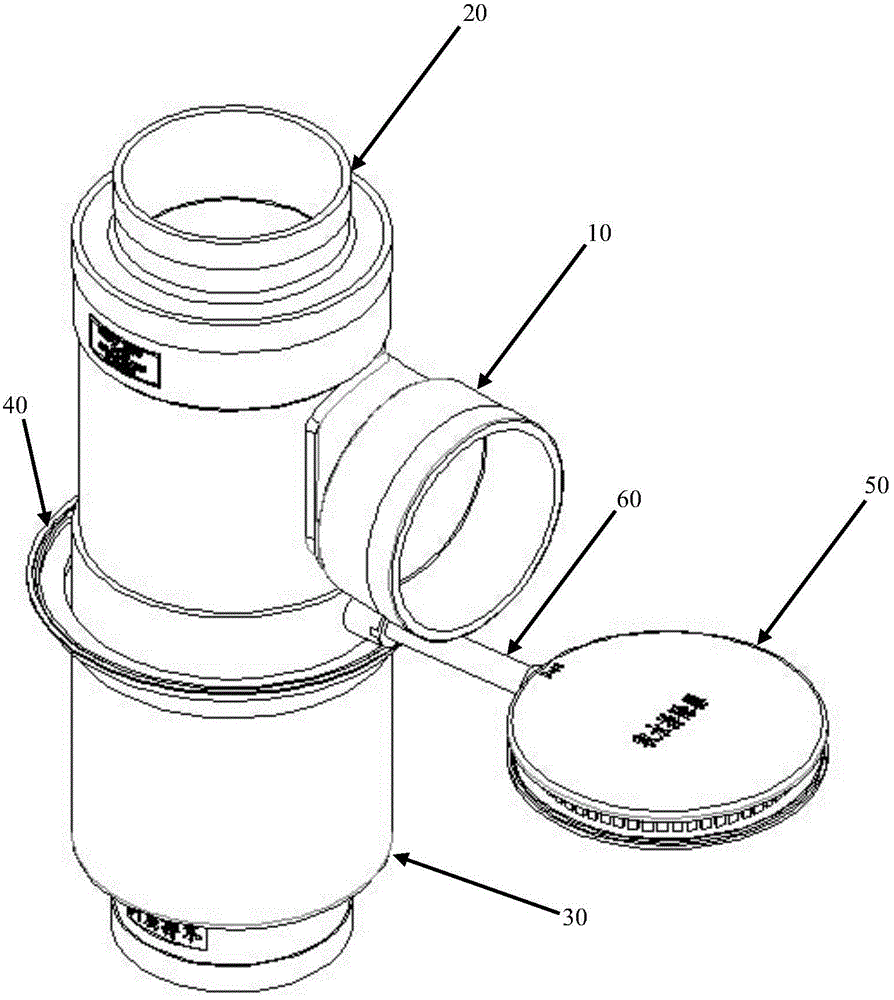

[0029] figure 1 It is a structural schematic diagram of the same-layer swirl tee in the embodiment of the present invention.

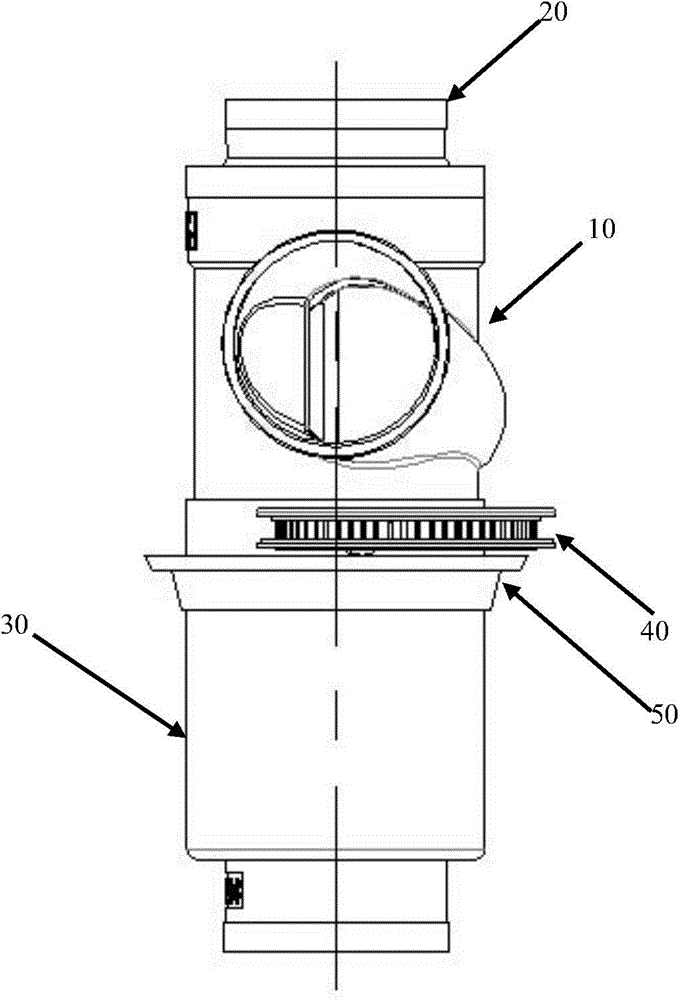

[0030] figure 2 It is the front view of the same-level swirl tee in the embodiment of the present invention.

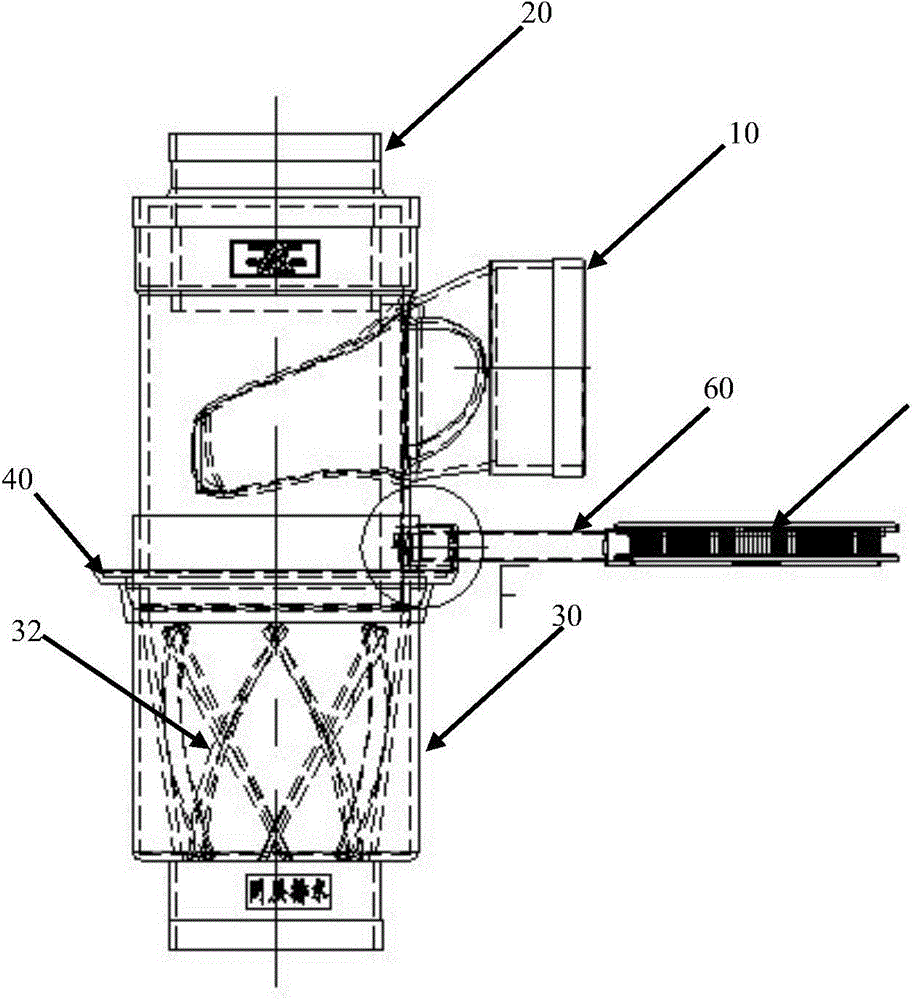

[0031] image 3 It is a full-section left view of the same-layer swirl tee in the embodiment of the present invention.

[0032] Figure 4 It is the top view of the same-layer swirl tee in the embodiment of the present invention.

[0033] Figure 5 It is an exploded schematic view of the same-layer swirl tee in the embodiment of the present invention.

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the swirl tee on the same floor includes: a tee main body 10 , a connecting cover 20 , a connecting pipe 30 , a round sleeve 40 , a drainer 50 and a connecting pipe 60 .

[0035] The three ends of the three-way pipe main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com