Method for measuring and calculating reverberation time in vehicle

A technology of reverberation time and calculation method, which is applied to the measurement of reverberation time, measuring device, and measurement of ultrasonic/sonic/infrasonic waves, etc., which can solve problems such as uneconomical and complicated processes, and achieve the effect of saving manpower, material resources and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below in conjunction with the drawings.

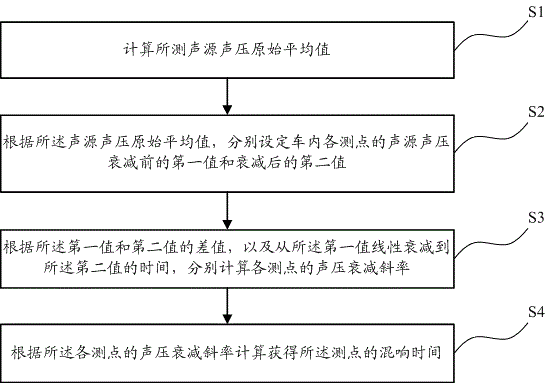

[0029] Please refer to figure 1 As shown, the first embodiment of the present invention provides a method for measuring and calculating reverberation time in a vehicle, including:

[0030] Step S1, calculating the original average sound pressure of the measured sound source;

[0031] Step S2, according to the original average value of the sound source sound pressure, respectively set the first value before the attenuation of the sound source sound pressure and the second value after the attenuation of the sound source at each measurement point in the vehicle;

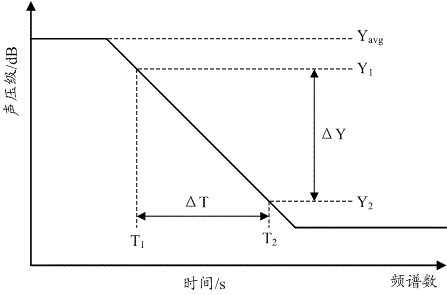

[0032] Step S3: Calculate the sound pressure attenuation slope of each measurement point according to the difference between the first value and the second value, and the time from the first value to linear attenuation to the second value;

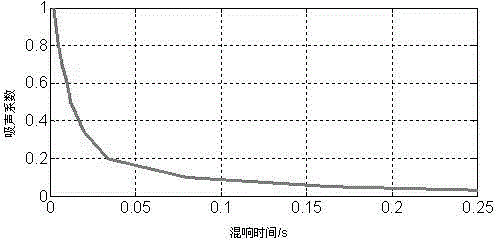

[0033] Step S4, calculating and obtaining the reverberation time of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com