Manufacturing method for high precision pentagonal prism

A manufacturing method, pentaprism technology, applied in prisms and other directions, can solve the problems of time-consuming, glue dispensing, walking around, and low work efficiency, and achieve the effect of novel methods and high rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe the present invention below in conjunction with specific embodiment:

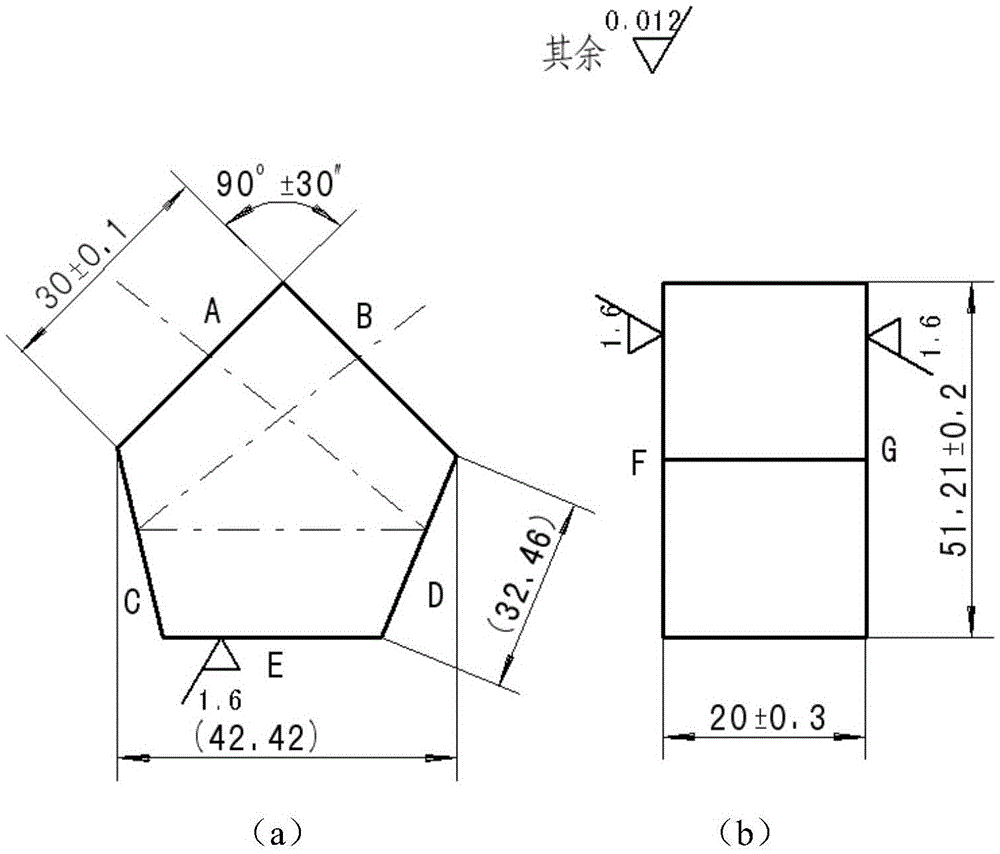

[0034] Step 1: Roughly grind and shape 2×4 pentaprism blanks by optical parts processing technology. Such as figure 1 As shown, the pentaprism blank size: 30±0.1mm, angle: 90°±30", first and second parallel difference ≤30". The two pentagonal end faces of the pentaprism blank are the F face and the G face, and the two sides perpendicular to each other are required to be the A face and the B face after the manufacture is completed, and the other side adjacent to the A face is the C face , the other side adjacent to the B surface is the D surface, and the side adjacent to the C surface and the D surface is the E surface, and the E surface can be roughly ground and formed. For fine grinding and polishing of the F surface, it is required that the number of apertures (number of interference fringes) N of the F surface satisfy -1≤N≤0, (+, - represent the high and low apertures respectively), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com