Touch screen, manufacturing method thereof, and display device

A manufacturing method and a display device technology, which are applied in the fields of instruments, computing, and electrical digital data processing, etc., can solve the problems of metal bridge wiring resistance reducing visibility, etc., and achieve the effects of solving visibility problems, reducing resistance, and increasing width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

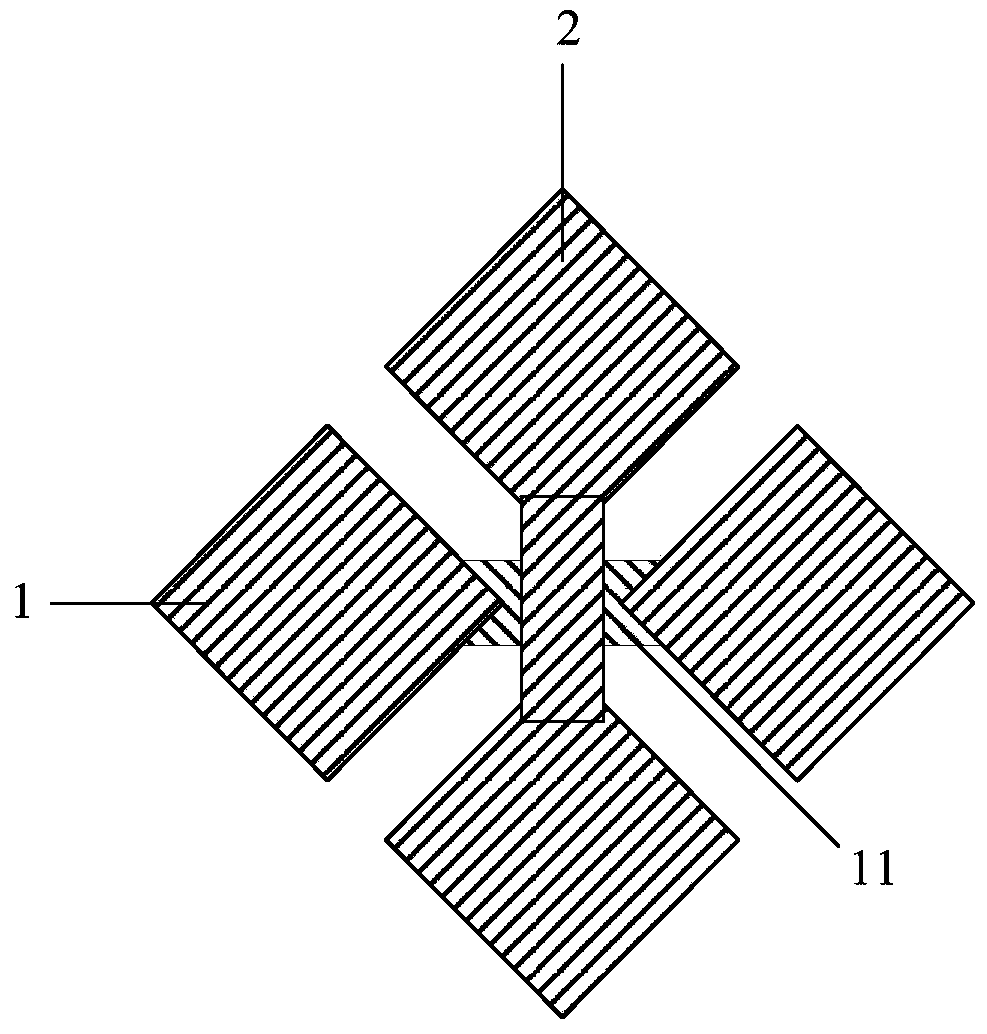

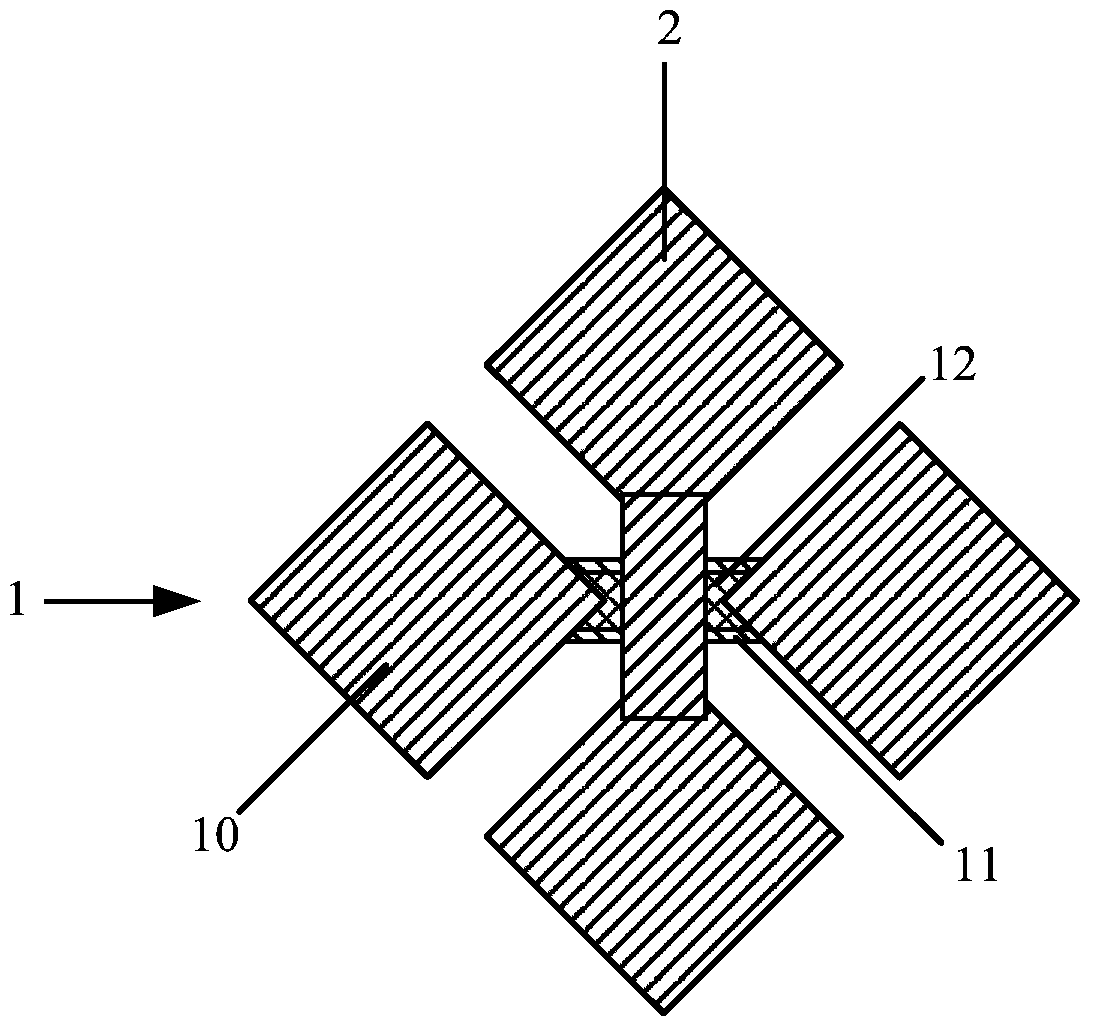

[0023] For a mutual capacitive touch screen, it includes driving electrodes and sensing electrodes for generating mutual capacitance, and the driving electrodes and sensing electrodes are intersected, and a detection capacitance matrix is formed at the intersections. The extending direction of the driving electrodes is set as the first direction, and the extending direction of the sensing electrodes is set as the second direction. For a single-layer mutual capacitive touch screen, the driving electrodes and sensing electrodes are formed by the same transparent conductive layer.

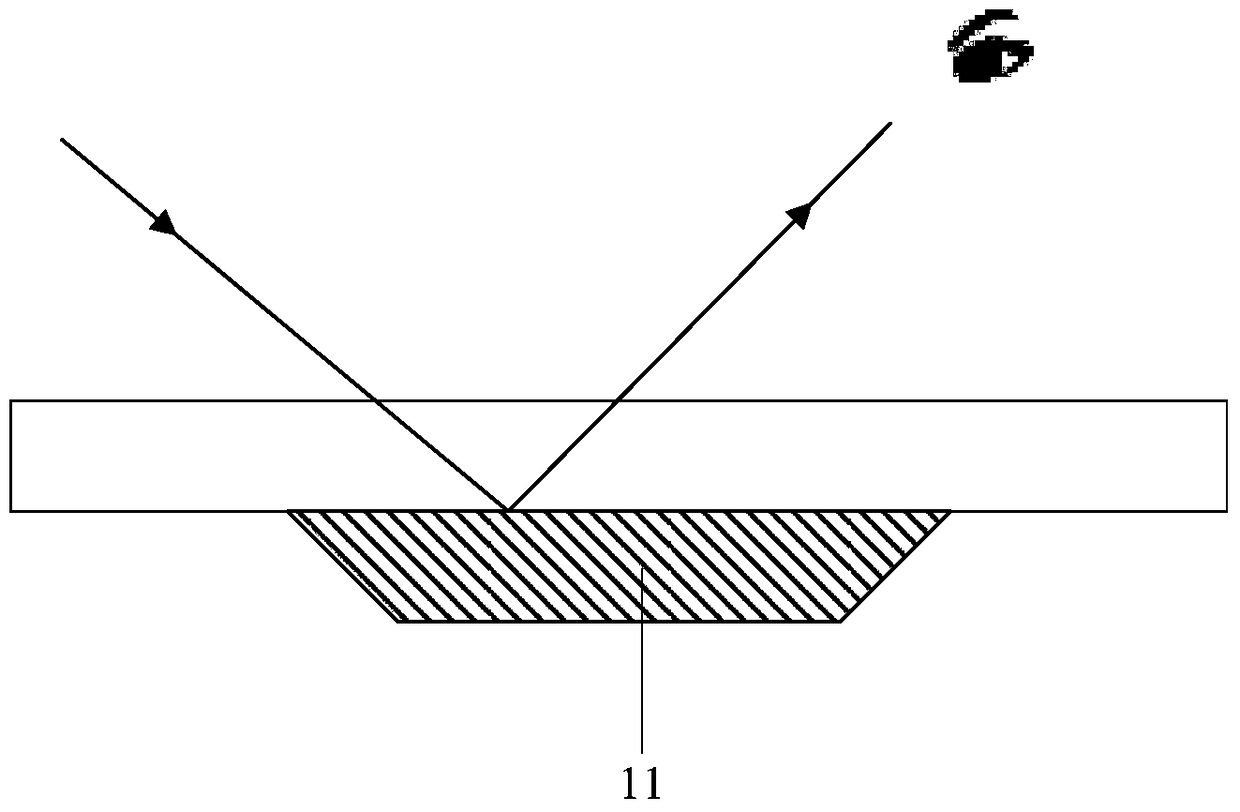

[0024] The touch screen provided by the present invention is a single-layer mutual-capacitance touch screen, and the touch screen includes first touch electrodes and second touch electrodes distributed along different directions, and the first touch electrodes and the second touch electrodes The electrodes are insulated at the intersecting position, the first touch electrode or the second touch elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com