Grain leftover inactivation and sterilization equipment

A technology for sterilization equipment and scraps, which is applied in the field of grain scraps inactivation and sterilization equipment, can solve the problems of difficulty in automation, incomplete processing, uneven heating, etc., and achieves improved processing effect, thorough processing, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

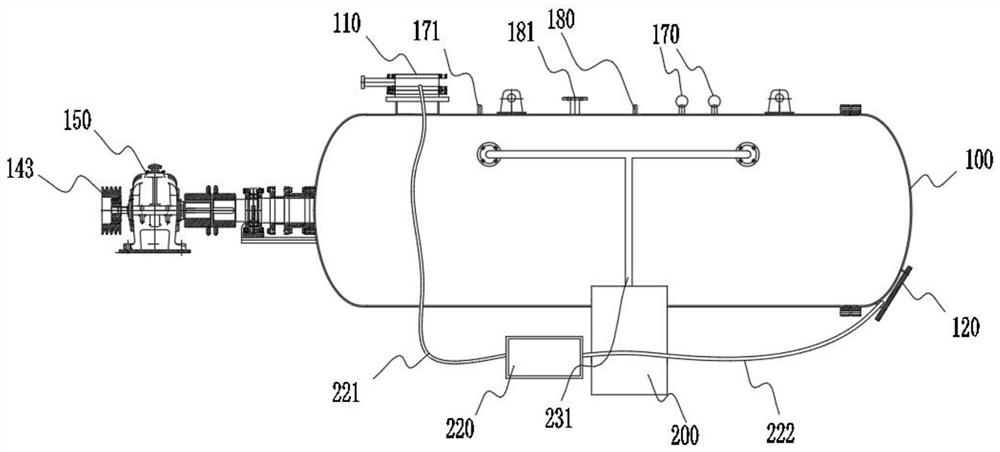

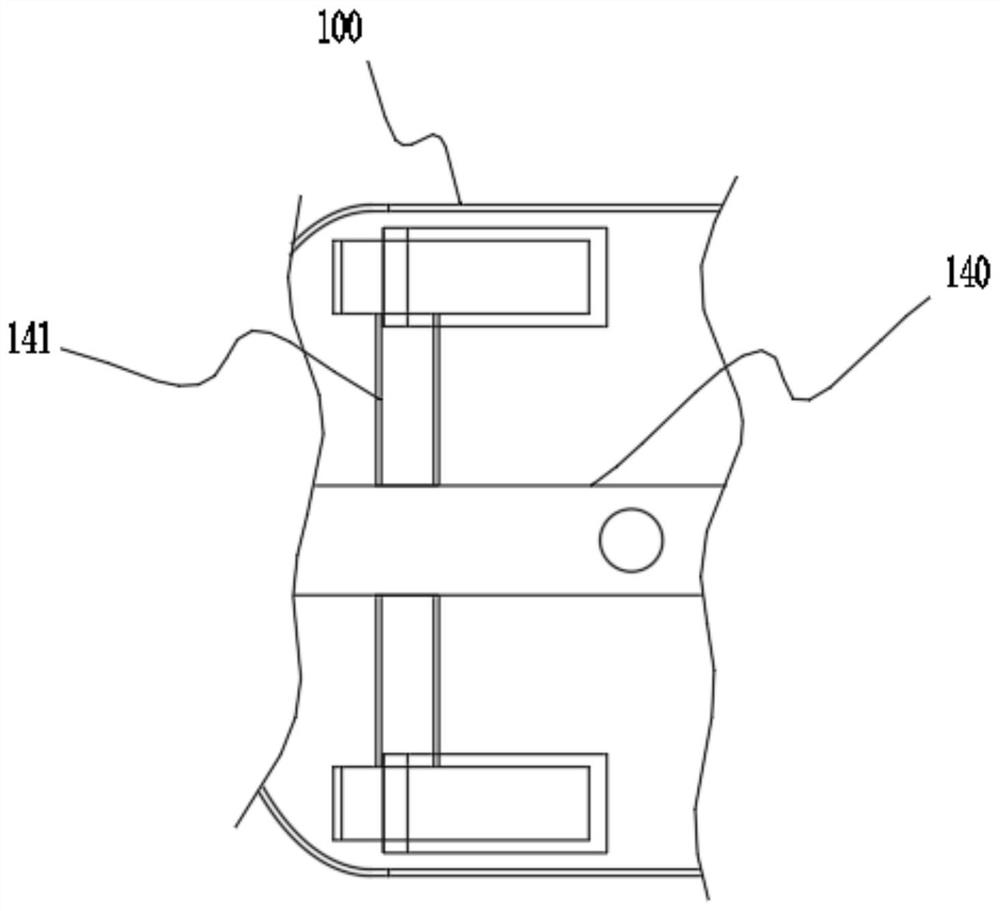

[0038] see Figure 1-Figure 8 As shown, the purpose of this embodiment is to provide grain waste inactivation and sterilization equipment, including a tank body 100 and a feed gate valve 110 arranged at the top of the tank body 100 for feeding, and arranged at the bottom of the tank body 100 for discharging. In addition, there is an air compressor 220 between the feed gate valve 110 and the discharge gate valve 120, and the air compressor 220 is connected with the feed gate valve 110 and the discharge gate valve 120 through an air line to close the feed gate valve 120. The gate valve 110 and the discharge gate valve 120 form a closed space. The inside of the tank body 100 is rotatably connected with a stirring shaft 140, and the outside of the stirring shaft 140 is fixedly connected with a stirring tooth 141, so as to stir the grain scraps with the pushing force generated by the rotation. The end of shaft 140 is provided with motor 150 and speed reducer 143, and the output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com