Weeding machine

A technology of working machine and working head, which is applied in the direction of agricultural machinery and implements, agriculture, harvesters, etc., and can solve the problems of the ground being planed, detached, and grassland meticulously treated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

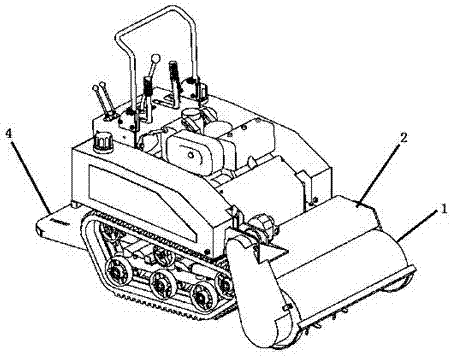

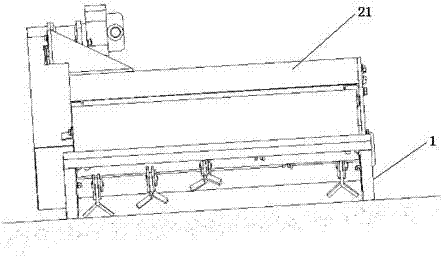

[0032] Combine below Figure 1 to Figure 15 Embodiments of the present invention are described in detail.

[0033] As shown in the figure, the weeding machine includes a chassis frame, a power control system installed above the chassis frame to provide power for the weeding machine and control the operating state of the weeding machine, a crawler-type traveling mechanism and a device installed below the chassis frame. The weeding operation head 1 at the front end of the chassis frame is characterized in that the weeding operation head 1 is connected to the chassis frame through a connection assembly 2;

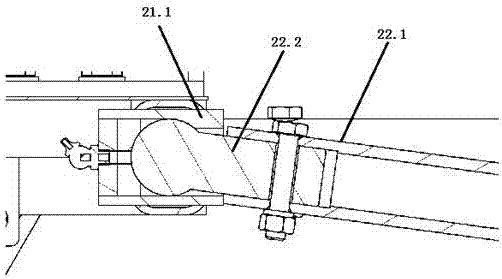

[0034] Described connection assembly 2 comprises the welding frame 21 that is arranged on the chassis frame front end, is used to connect the lifting bar 22 of welding frame 21 and chassis frame, is used to install the working head mounting plate 23 of weeding operation head 1 and is used for The hydraulic motor 24 that the weeding operation head 1 provides power, two lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com