Full-automatic apple peeling machine

A peeling machine, fully automatic technology, applied in peeling appliances, household appliances, applications, etc., can solve laborious, time-consuming, error-prone and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

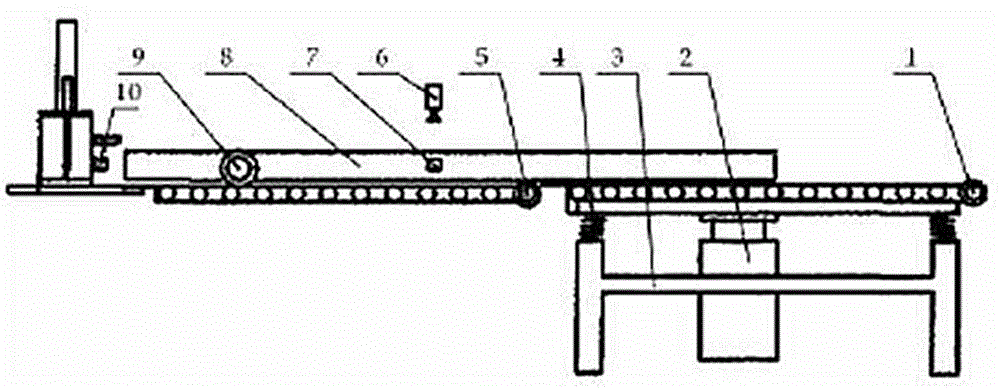

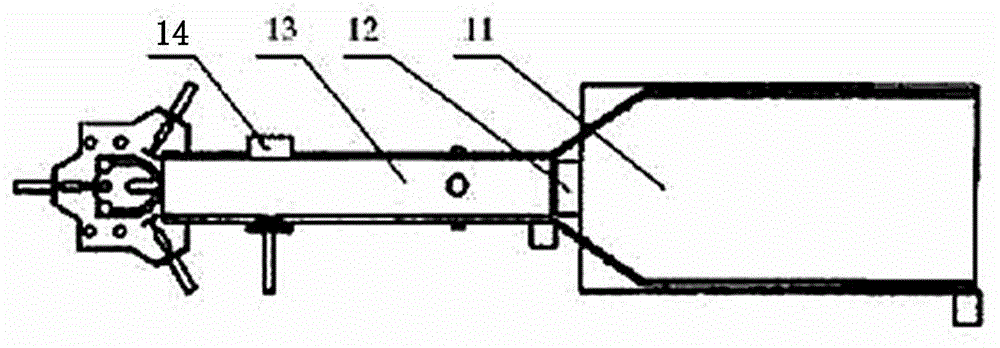

[0017] exist figure 1 Among them, the apple warehouse is connected with the vibrating conveying device 2, and vibrates laterally in the horizontal plane at a certain frequency, so that most of the apples can be adjusted to a state where the axis of the core is perpendicular to the horizontal plane, and the apples are conveyed by the conveyor belt 11 through the connecting plate 12 Arrive at fast conveyer belt 13, when passing through first photoelectric sensor 7, pattern recognizer 6 took the top view of this apple and processed by computer, if the axis of the core is perpendicular to the horizontal plane, then the apple is released from the cylinder 9 and the push rod does not move, and the apple goes smoothly. Pass; otherwise release cylinder 9 push rods to stretch out and apples are released, and the apples return to the feed bin to accept the identification and selection of the next round.

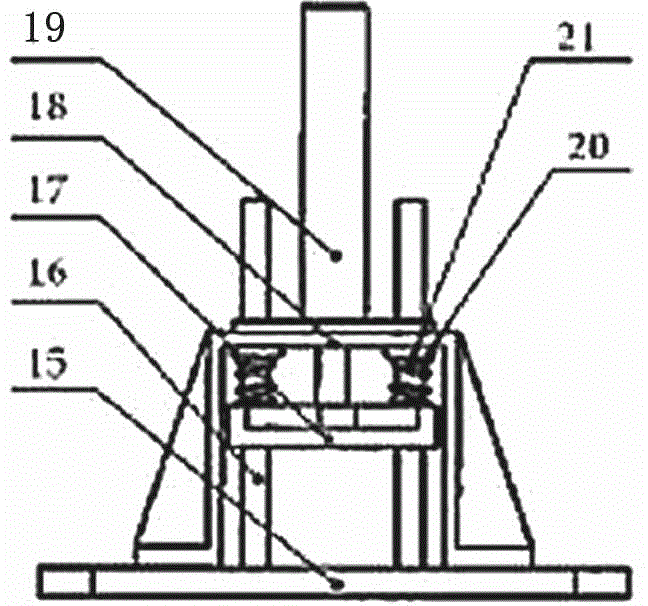

[0018] exist Figure 3a and 3b Among them, the apple pallet 23 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com