Anti-falling glass milk bottle and production method therefor

A glass and baby bottle technology, applied in chemical instruments and methods, glass/slag layered products, feeding bottles, etc., can solve problems such as difficult cleaning, residual harmful substances, and poor heat preservation effect, so as to achieve good heat preservation effect and good anti-corrosion perm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

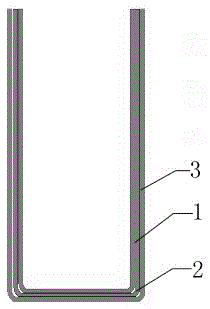

[0037] Example 1, such as figure 1 As shown, a kind of anti-shattering glass feeding bottle includes a plastic shell 3, and the plastic shell 3 is made of transparent plastics such as PP or PPSU or PA. The setting of the plastic shell 3 reduces the deformation of the feeding bottle when the feeding bottle collides, and is smoother and easier to clean than the drop-resistant feeding bottle protected by the silicone sleeve.

[0038] In order to reduce the weight of the whole feeding bottle, the thickness of the plastic shell 3 can be thinner than that of common feeding bottles. The thickness of the plastic shell 3 can be reduced to 0.5mm.

[0039] The glass feeding bottle also includes an inner container 1 made of glass. The inner container 1 has the advantages of safety, easy cleaning, aging resistance and the like.

[0040] In order to reduce the weight of the whole feeding bottle, the thickness of the glass liner 1 can be thinner than that of ordinary glass feeding bottles....

Embodiment 2

[0044] Embodiment 2, a kind of preparation method of shatter-resistant glass feeding bottle, comprises the steps:

[0045] 1. Assembling steps, put the clean glass liner 1 into the clean plastic shell 3;

[0046] 2. Filling step, use the filling equipment tool to pour the silica gel (multi-component silica gel to adjust the proportion of each component and stir evenly) from the gap between the glass liner 1 and the plastic shell 3 until it fills the whole up to the gap;

[0047] Care should be taken throughout the perfusion process to prevent air bubbles from forming in the silicone filling layer 2. Finally, according to the curing conditions of the silica gel, the silica gel filling layer 2 is fully cured by heating or standing at room temperature for a period of time.

[0048] Another preparation method of an anti-break glass feeding bottle comprises the steps of:

[0049] 1. Filling step, first use the filling equipment tool to inject a certain amount of silica gel (mult...

Embodiment 3

[0051] Example 3, such as figure 1 As shown, a kind of anti-shattering glass feeding bottle includes a plastic shell 3, and the plastic shell 3 is made of transparent plastics such as PP or PPSU or PA. The setting of the plastic shell 3 reduces the deformation of the feeding bottle when the feeding bottle collides, and is smoother and easier to clean than the drop-resistant feeding bottle protected by the silicone sleeve.

[0052] In order to reduce the weight of the whole feeding bottle, the thickness of the plastic shell 3 can be thinner than that of common feeding bottles. The thickness of the plastic shell 3 can be reduced to 2mm.

[0053] The glass feeding bottle also includes an inner container 1 made of glass. The inner container 1 has the advantages of safety, easy cleaning, aging resistance and the like.

[0054] In order to reduce the weight of the whole feeding bottle, the thickness of the glass liner 1 can be thinner than that of ordinary glass feeding bottles. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com