reverse dust collector

A technology of dust collector and dust removal chamber, which is applied in the direction of chemical instruments and methods, dispersed particle filtration, combined devices, etc. It can solve the problems of affecting normal operation, secondary dust raising, and inconvenient cleaning, so as to achieve obvious dust removal effect and improve purification Effect, the effect of preventing secondary lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

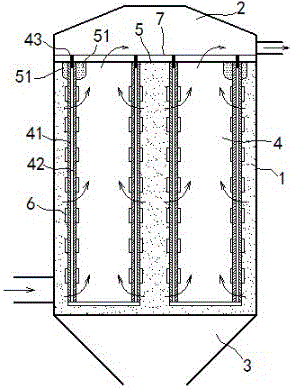

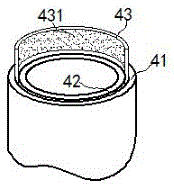

[0014] exist figure 1 , figure 2 In the shown embodiment, the reverse dust collector includes a dust removal chamber 1, a dust removal cylinder 4, a clean chamber 2 and an ash hopper 3; Below; a partition 5 is installed between the purification chamber 2 and the dust removal chamber 1; an air intake pipe is installed on the side wall of the dust removal chamber 1, and an exhaust pipe is installed on the side wall of the purification chamber 2; each of the dust removal chambers The cylinders 4 are vertically installed in the dust removal chamber 1, and the tops of the dust removal cylinders 4 are equidistantly installed on the partition 5; the dust removal cylinders 4 include an outer cylinder 41, an inner cylinder 42 and an isolation ring 43 The outer cylinder 41 and the inner cylinder 42 are coaxially sleeved, and the outer cylinder 41 and the inner cylinder 42 are driven to rotate freely by two drivers 51 fixed on the partition plate 5 respectively; Electromagnetic sheets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com