Wheel hub washing and paint spraying combined production line

A technology of cleaning line and painting line, which is applied in the direction of spraying device, cleaning method and equipment, pretreatment surface, etc. It can solve the problems of uneven quality of batch products, large production workshop area, and high labor intensity of workers. Achieve the effect of saving procurement costs, reducing labor costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

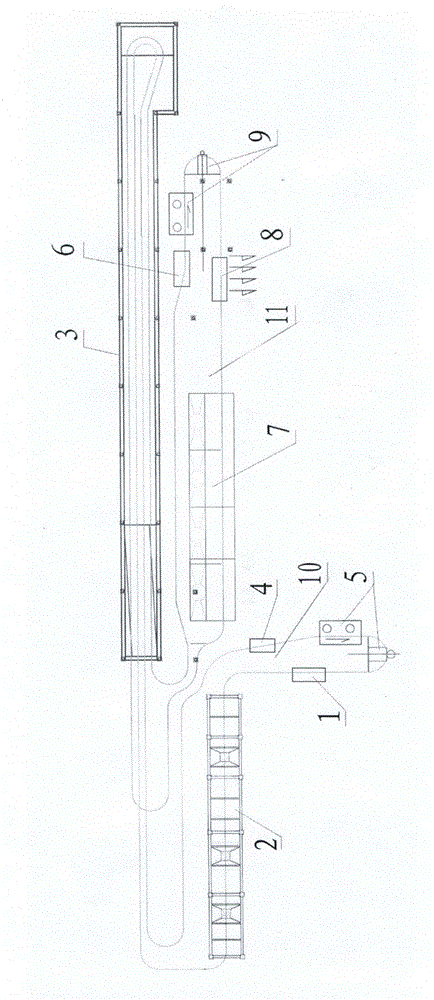

[0016] see figure 1 , among the figure, the combined production line of hub cleaning and painting of the present invention comprises cleaning line 10, painting line 11 and drying furnace, and described cleaning line and painting line are respectively independent annular closed production lines, and have partial overlapping; Cleaning line and painting line The lines are staggered up and down at the overlap, and share a drying oven outside the overlap.

[0017] The cleaning line includes a part 1 on the cleaning line, a cleaning mechanism 2, a common drying oven 3, a part part 4 on the cleaning line, and a conveyor unit 5 on the cleaning line.

[0018] The paint spraying line includes a part 6 on the painting line, a painting mechanism 7, a common drying furnace 3, a part 8 on the painting line and a conveying unit 9 on the painting line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com