A dust collector filter element cleaning measurement and control device

A technology of measurement and control devices and dust collectors, which is applied in the direction of instruments, simulators, program control, etc., can solve problems such as energy waste, equipment wear, and failure to achieve dust cleaning effect, so as to reduce wear, improve service life, and run cycle long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

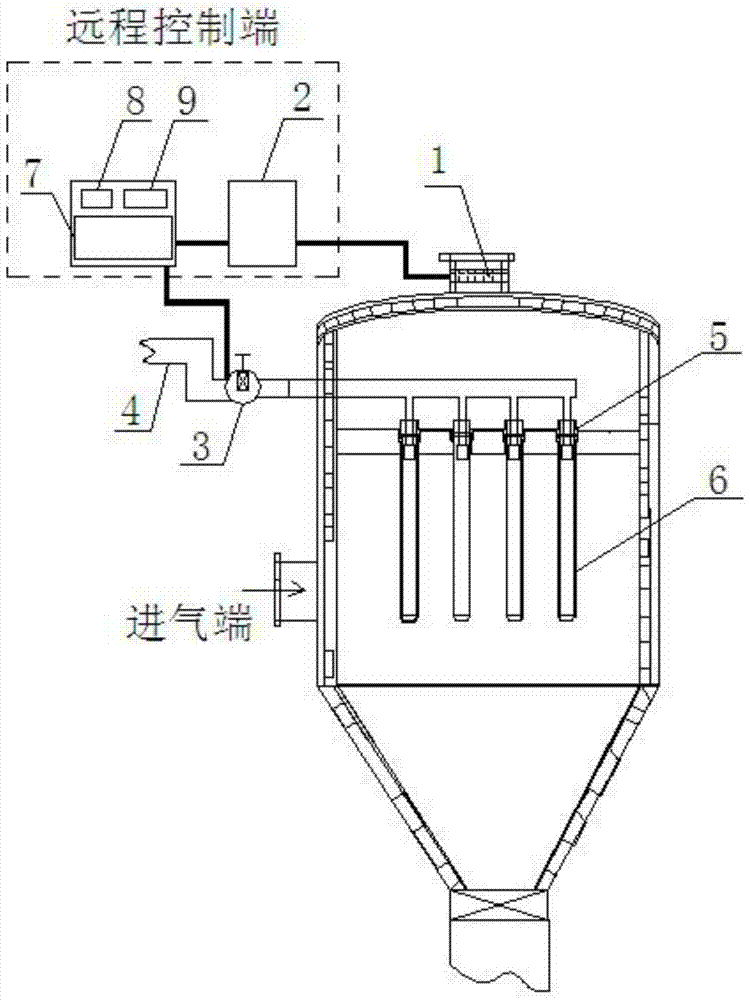

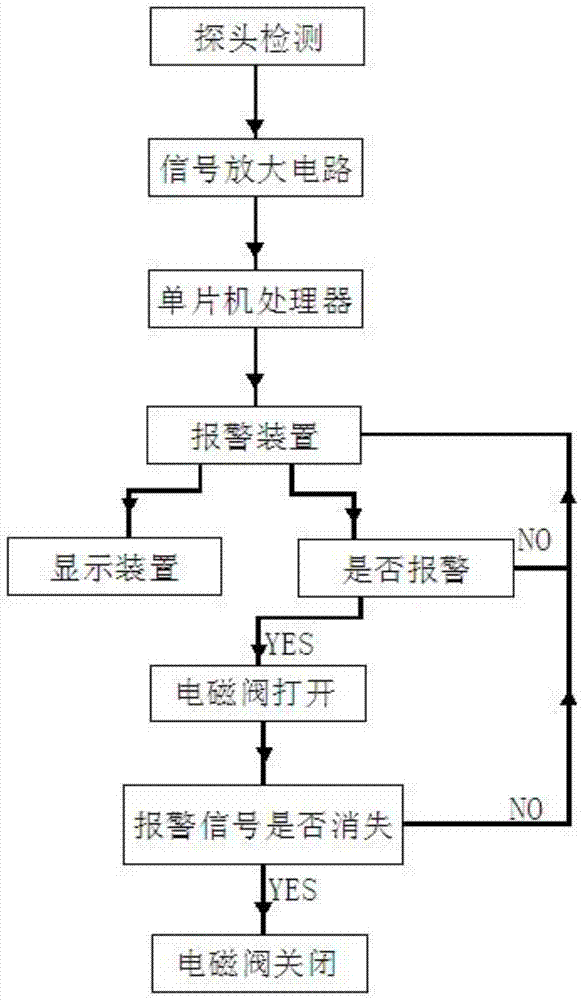

[0027] Such as figure 1 , figure 2 , image 3 As shown, a dust removal measurement and control device for a filter element of a dust collector includes a detection sensor, an alarm device and a control device. The detection sensor includes a probe 1 and a signal processor 2 connected to the probe, and the probe is located at the air outlet of the output end of the filter element. The input end of the alarm device is connected to the output end of the signal processor, and the output end of the alarm device is connected to the input end of the control device.

[0028] The signal processor includes a signal amplifying circuit and a single-chip processor connected in sequence.

[0029] Described control device is electromagnetic control valve 3, and described electromagnetic control valve is connected blowing gas conveying pipe 4, and is provided with nozzle 5, and described nozzle contacts with filter core 6 of dust remover and corresponds one by one, and described blowing ga...

Embodiment 2

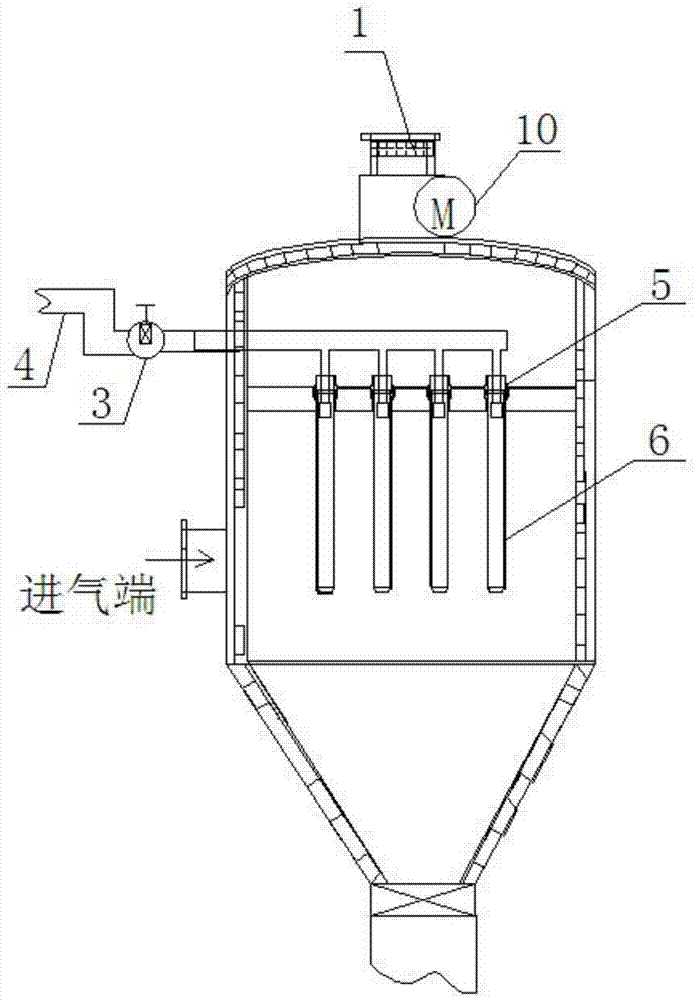

[0045] A dust removal measurement and control device and measurement and control method for a filter element of a dust collector. The difference from Embodiment 1 is that in the equipment involved, a centrifugal fan 10 is installed at the air outlet of the dust collector, and the detection sensor probe 1 is installed at the air outlet of the centrifugal fan. .

Embodiment 3

[0047] A dust removal measurement and control device and a measurement and control method for a filter element of a dust collector, the difference from Embodiment 1 is that the measured gas of the detection sensor is hydrogen sulfide H in dusty gas 2 S, the difference in principle is that the redox reaction of the measured gas on the sensitive electrode is different, and the equation is:

[0048] Hydrogen sulfide (H 2 S): H 2 S+4H 2 O→H 2 SO 4 +8H + +8e - .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com