Dip machine

A technology of dipping and slurrying, which is applied in the field of slurrying machines, can solve the problems of high production cost and low utilization rate of slurry, and achieve the effect of increasing utilization rate, reducing usage, and increasing slurry utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

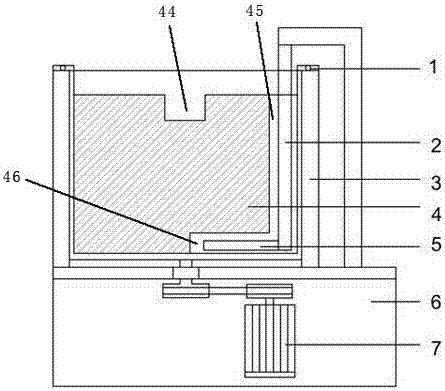

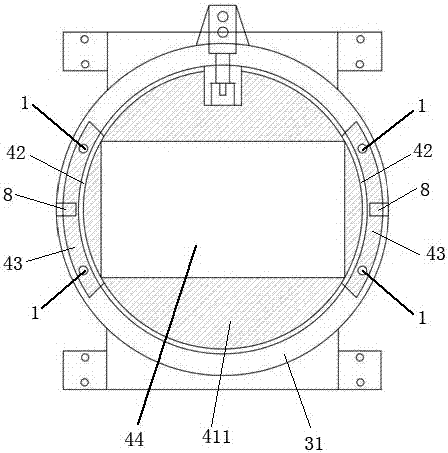

[0021] See figure 1 , the slurry dipping machine of the present invention, which includes a slurry tank 3, a rotary drive device 7, a scraper 5 and an insert 4, the slurry tank 3 is rotatably mounted on a base 6, and a rotary drive device is installed in the base 6 7. The power output end of the rotary drive device 7 is connected to the bottom of the slurry tank 3, the scraper 5 is installed in the slurry tank 2 through the pillar 2, and the insert 4 is detachably filled and installed in the slurry tank 3; the insert 4 It includes a main body 41, a top fastening part 43 and a side connecting part 42. The main body 41 is provided with a cavity 44 for accommodating the mold shell to be dipped. The top fastening part 43 is integrally connected with the main body 41 through the side connecting part 42. The top fastening part 43 is pressed on the barrel wall top surface 31 of the slurry barrel 3 by the positioning pin 1; The fastening part 43 is further pressed against the top sur...

Embodiment 2

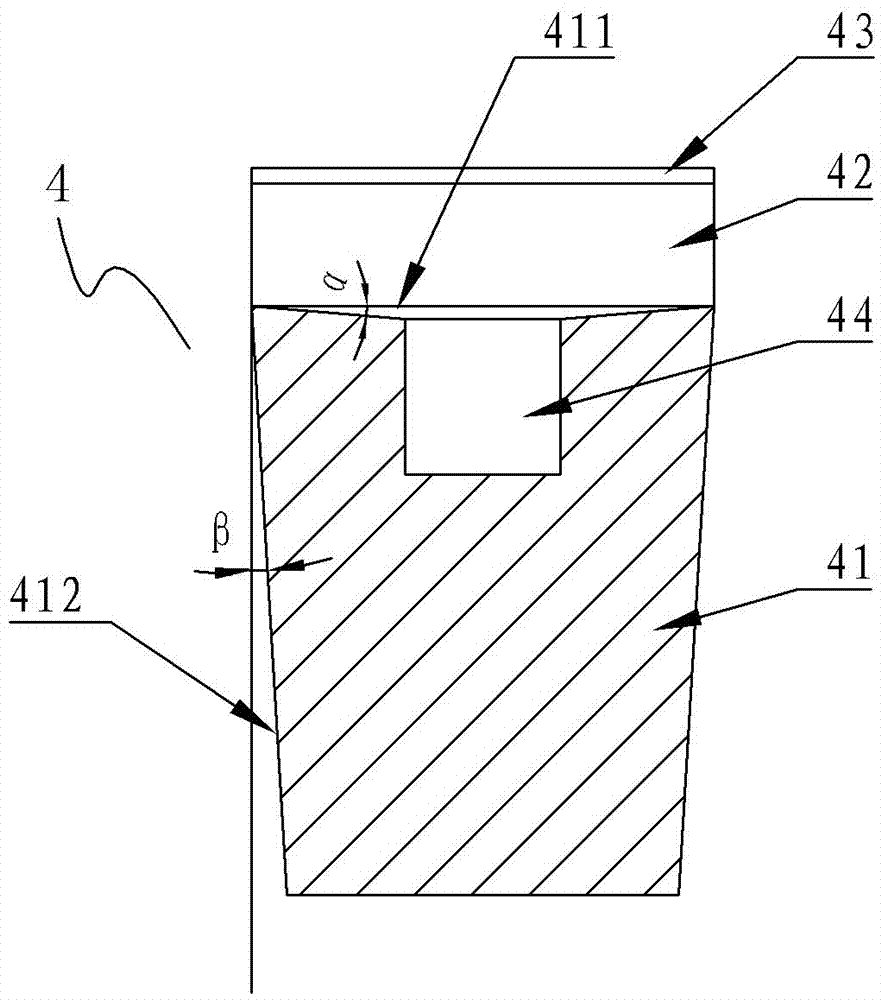

[0026] The difference between the second embodiment and the first embodiment is that the cavity 44 provided on the insert body 41 is formed by connecting multiple parting cavities, see image 3 , which includes a cross-shaped cavity 44a arranged on the top plane of the insert body 41, four vertical cavities 44b arranged in parallel on the insert body 41, and the cross-shaped cavity 44a communicates with the four vertical cavities 44b .

[0027] When the profile structure of the formwork to be stained with slurry is complex and the cavity structure of the corresponding structure on the insert body 41 is also complicated, the cavity 44 is configured into multiple sub-cavities, and the multiple The parting cavities are configured to communicate with each other to ensure that the entire cavity 44 can reliably accommodate the formwork to be dipped in slurry and the slurry can fully flow into the entire cavity 44, thereby ensuring sufficient and even slurrying of the formwork.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com