A copper strip slitting device with speed self-adaptive function

A self-adaptive, copper-belt technology, applied in the attachments of shearing machines, shearing devices, manufacturing tools, etc., can solve the problem of copper-belt underpinning, the difficulty for operators to adjust the unit equipment, and affect the efficiency of equipment operation. and other problems, to achieve the effect of easy operation for workers, avoiding copper tape support or stretching and scrapping, and efficient equipment operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

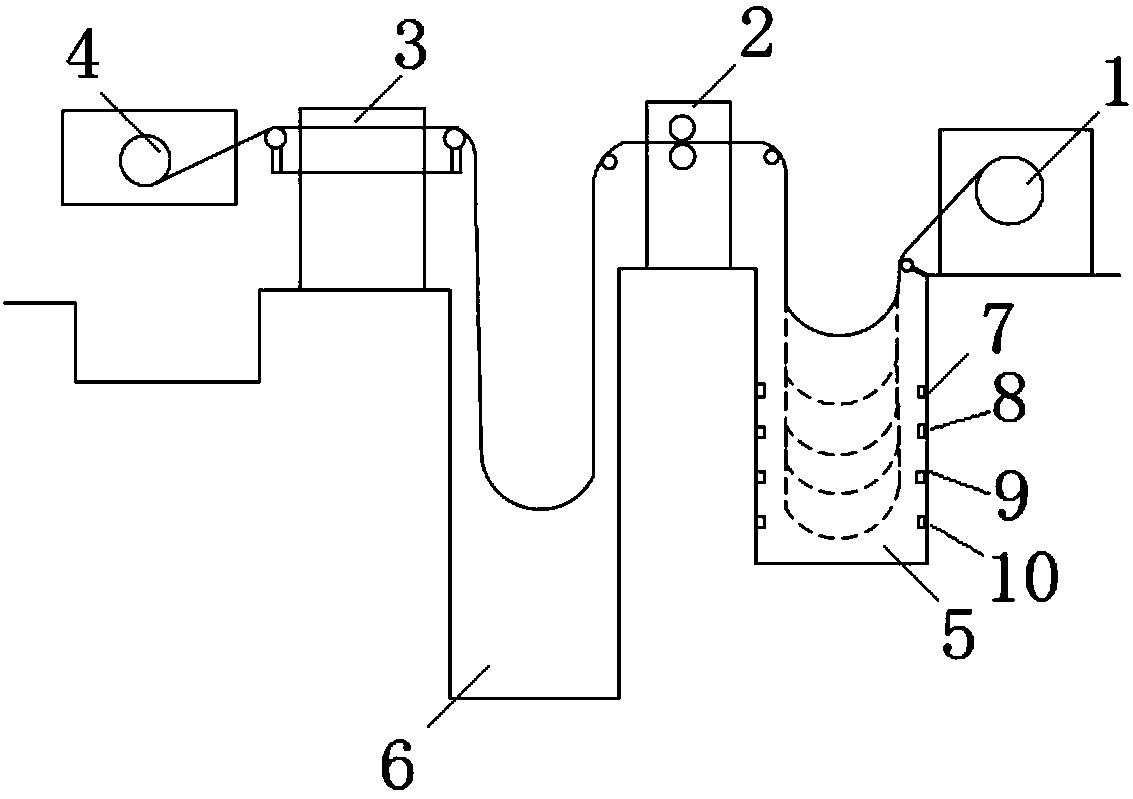

[0018] Such as figure 1 As shown, the copper strip slitting device with speed adaptive function includes an unwinder 1, a slitting mechanism 2, a tension table 3 and a winding machine 4 arranged in sequence, wherein the unwinding machine 1 and the slitting mechanism There is an unwinding pit 5 between the 2, and a winding pit 6 between the slitting mechanism 2 and the tension table 3; the setting of two looper pits can ensure the stable operation of the slitting device.

[0019] The slitting device also includes a governor for adjusting the unwinding speed of the unwinder and a group of photoelectric sensors for detecting the position of the copper strip, and the photoelectric sensors are connected with the governor. The governor is set on the unwinding machine, and there are four photoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com