Hydraulic shock absorber for automobile

A hydraulic shock absorber and shock absorber technology, applied in shock absorbers, liquid shock absorbers, springs/shock absorbers, etc., can solve the hidden dangers of car body safety, only focus on buffering effect, and car body damage, etc. Personal safety, avoid body damage, and increase the effect of circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

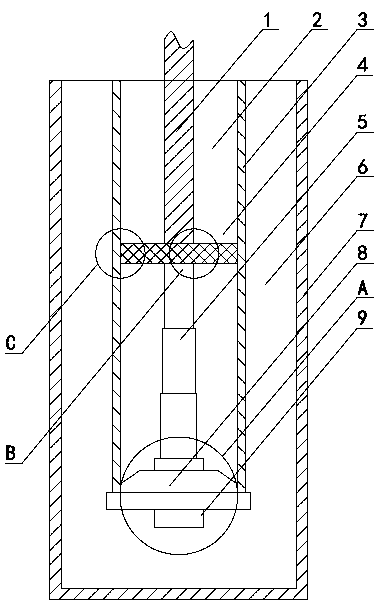

[0038] Such as figure 1 Shown, a kind of automobile hydraulic shock absorber, comprises shock absorber shell 7, is provided with piston barrel 3 inside shock absorber shell 7, and the inside of piston barrel 3 forms the first oil chamber 2 of this automobile hydraulic shock absorber , The second oil chamber 6 of the automobile hydraulic shock absorber is formed at intervals between the piston cylinder 3 and the shock absorber housing 7 .

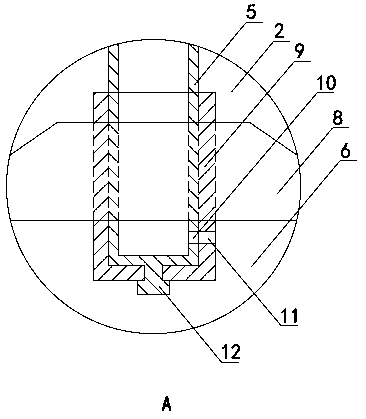

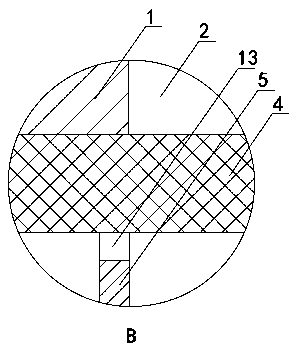

[0039] A piston body 4 is arranged in the piston barrel 3, and one end of the piston rod 1 is fixed at the center of the piston body 4, and the other end is output upward from the upper port of the piston barrel 3, and the piston rod 1 drives the piston body 4 to reciprocate in the piston barrel 3 . A base 8 is also installed at the bottom of the piston cylinder 3, the base 8 communicates with the first oil chamber 2 and the second oil chamber 6, when the piston body 4 moves upward or downward, the oil will pass through the base 8 at the sa...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is: as Figure 9 As shown, in this embodiment, the throttling tube 9 is transparent up and down, and a connecting frame 25 is provided at the same time. . After the rotating shaft at the bottom of the telescopic rod 5 passes through the upper end surface of the connecting frame 25, the block 12 is set.

Embodiment 3

[0061] The difference between this embodiment and embodiment 1 is: as Figure 10 As shown, in this embodiment, the telescopic rod 5 is upside down and has a polygonal overall cross-section. . A lower turntable 26 is arranged at its lower end, the cross section of the lower turntable 26 is circular and is provided with an upward opening, and the blocking platform 12 is arranged on the bottom of the lower turntable 26 . The outer ring of the lower turntable 26 is attached to the inner ring of the throttle tube 9 . The lower opening 10 of the telescopic rod is provided on the side wall of the lower brick platform 26 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com