Thirteen-freedom spraying robot for outer surface of large ship body

A spraying robot and degree-of-freedom technology, which is used in manipulators, spraying devices, program-controlled manipulators, etc., can solve the problems of high requirements on the surface smoothness of the hull, low spraying quality, and high reverse spray rate, and achieves improved spraying range, light weight, The effect of a large working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

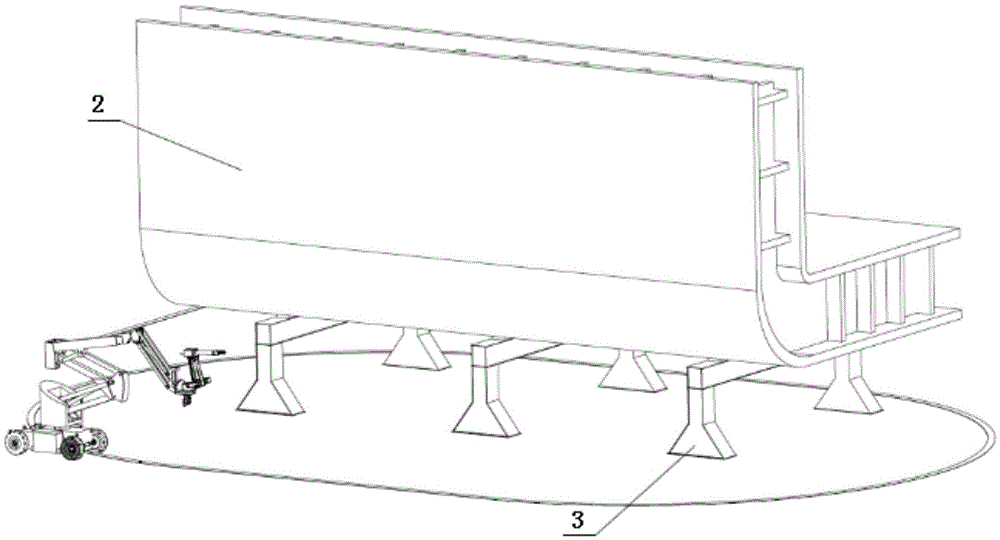

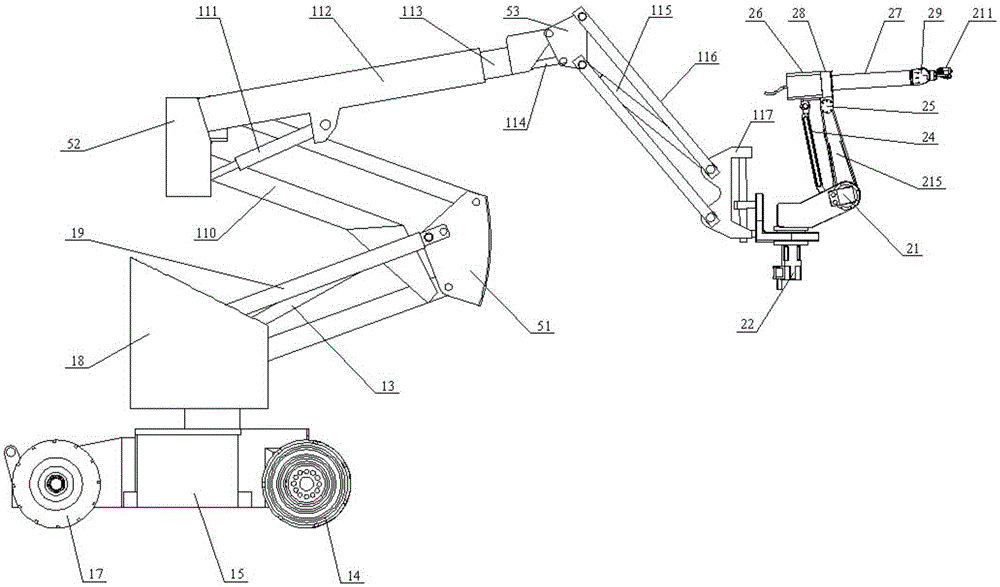

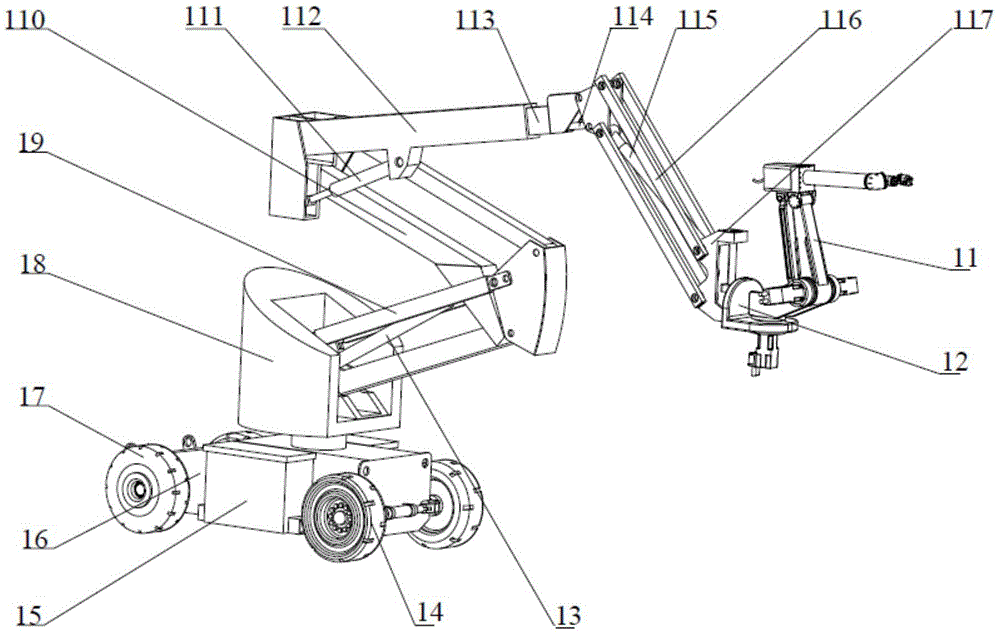

[0029] Specific implementation mode one: combine figure 1 , figure 2 and image 3Describe this embodiment. This embodiment includes a mobile vehicle body, a seven-degree-of-freedom hydraulic extension arm and a six-degree-of-freedom lightweight manipulator. On the car body, the six-degree-of-freedom lightweight manipulator is set on a seven-degree-of-freedom hydraulic arm;

[0030] The seven-degree-of-freedom hydraulic boom includes a counterweight turntable 18, a first boom 19, an auxiliary boom 110, a main boom 112, a telescopic boom 113, a short boom 116, a rotating support connector 117, a first hydraulic cylinder, and a second hydraulic cylinder. Cylinder 13, third hydraulic cylinder 111, fourth hydraulic cylinder, fifth hydraulic cylinder 114, sixth hydraulic cylinder 115, first connecting member 51, second connecting member 52 and third connecting member 53, the counterweight turntable 18 It is arranged on the mobile car body and rotates with the mobile car body. Th...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 and Figure 9 Describe this embodiment, in this embodiment, the manipulator body includes a first explosion-proof servo motor 22, a second explosion-proof servo motor 21, a third explosion-proof servo motor 213, a rotating base 23, an external connecting rod 24, an elbow support 25, and an explosion-proof casing 26. Forearm connector 28, forearm 27, wrist middle section 29, wrist end 210, spray gun connector 212, spray gun 211 and second big arm 215, the first explosion-proof servo motor 22 is connected to the motor flange 46 The lower end surface of the loading platform 12, the rotating base 23 is arranged on the upper end surface of the loading platform 12 and its bottom is connected with the output shaft of the first explosion-proof servo motor 22, and the bottom of the second big arm 215 is hinged on the rotating base 23 Above, the second explosion-proof servo...

specific Embodiment approach 3

[0039] Specific implementation mode three: combination Figure 8 , Figure 9 and Figure 10 Describe this embodiment. In this embodiment, the manipulator body further includes a first RV reducer 47 , and the first RV reducer 47 is arranged between the second explosion-proof servo motor 22 and the rotating base 23 .

[0040] In this embodiment, the manipulator body also includes a second RV reducer 45 and a third RV reducer 42, the second RV reducer 45 is arranged between the second explosion-proof servo motor 22 and the rotating base 23; the third RV The speed reducer 42 is arranged between the third explosion-proof servo motor 213 and the rotating base 23 .

[0041] In this embodiment, the third explosion-proof servo motor 213 is installed on the motor base 214, and through the deceleration of the third RV reducer 42, it drives the second big arm 215 to rotate, and the reduction ratio is 110:1; the installation method of the first explosion-proof servo motor 21 Same as abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com