Closestool with efficient flushing waterway

A toilet and waterway technology, applied in flushing toilets, water supply devices, buildings, etc., can solve problems such as not easy to outline a smooth waterway, affect flushing function, short steering stroke, etc., achieve good dredging effect and improve water flow energy , Increase the effect of steering stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

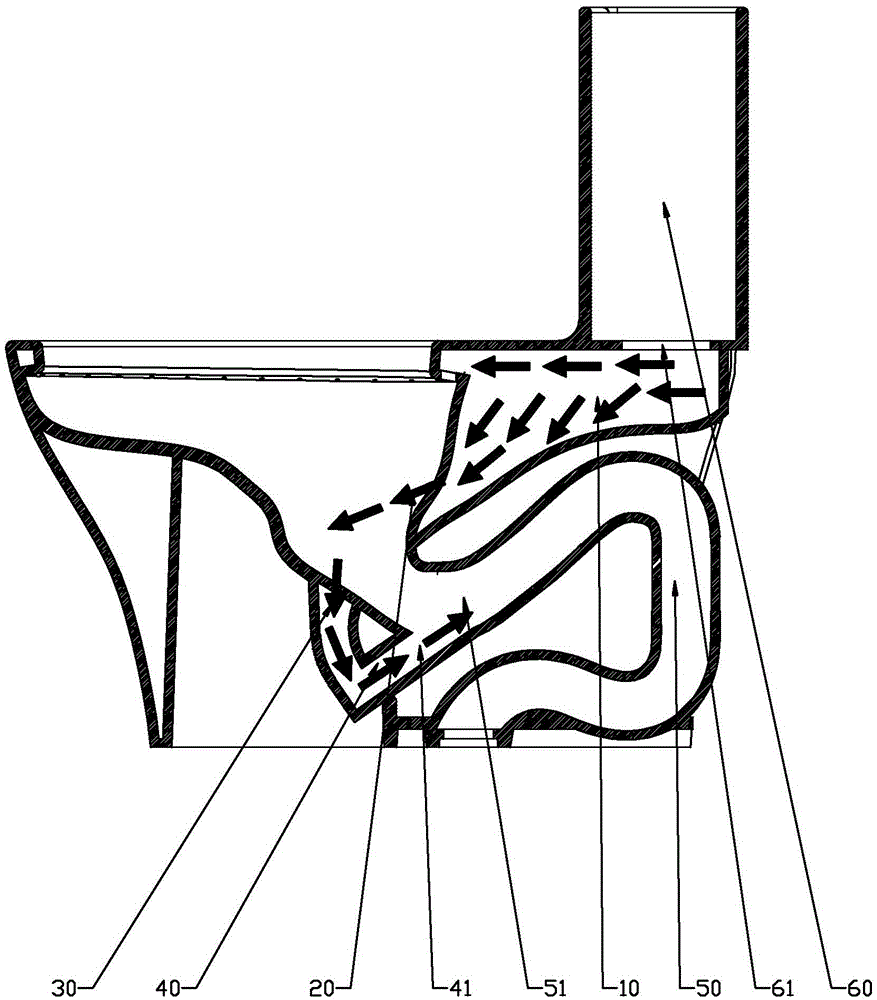

[0029] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

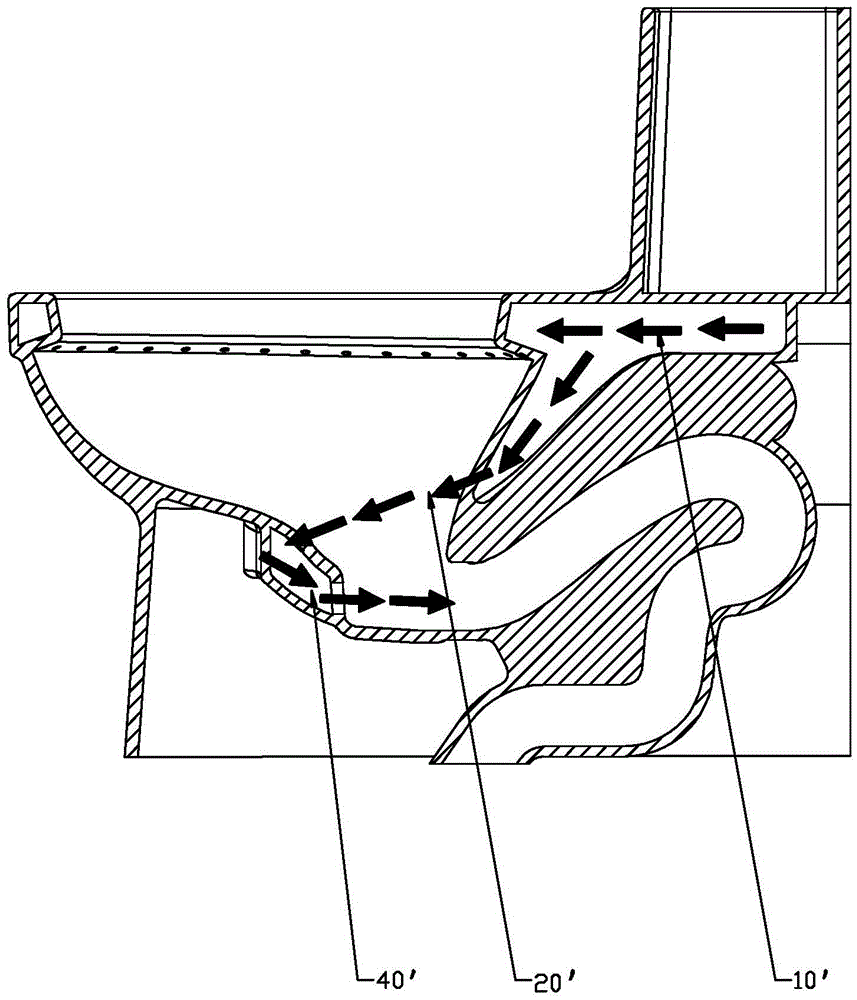

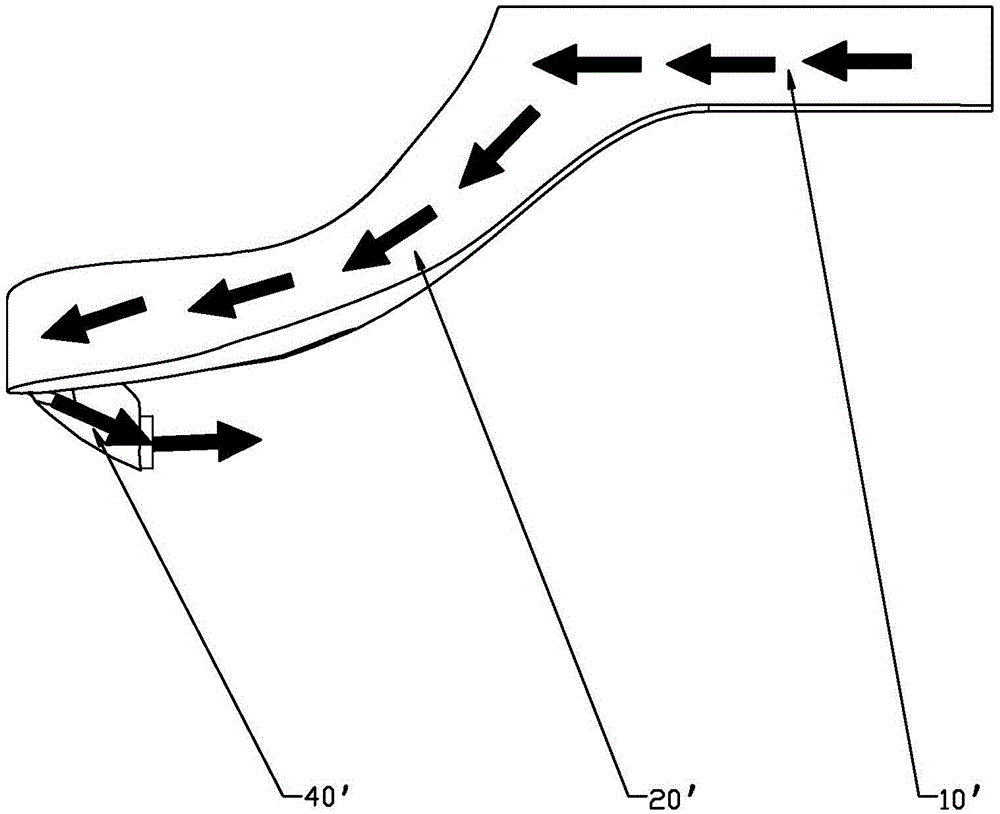

[0030] Such as image 3 with Figure 4 As shown, a toilet with a high-efficiency flushing waterway of the present invention includes a jetting waterway supplying water to the jetting port 41 of the toilet and a sewage drainage way 50 connected to the sewage outlet 51 of the toilet. In this embodiment, the drainage channel 50 adopts a siphon channel with double traps. The spraying water path includes a horizontal diversion section 10 , an inclined diversion section 20 , a discharge section 30 and a jet section 40 which are sequentially connected.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com