Sucker rod centralizer having better universality

A technology of sucker rods and centralizers, which is applied in the direction of drill pipes, drilling equipment, earthwork drilling and production, etc., which can solve the problems of poor versatility and achieve better versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

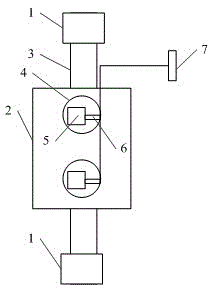

[0023] In Embodiment 1, a sucker rod centralizer with better versatility is provided, please refer to figure 1 , the sucker rod centralizer includes:

[0024] Coupling 1, centralizing sleeve 2, pup joint 3, the coupling is set at both ends of the pup joint, the coupling is used to connect and fix the sucker rod, and the centralizing sleeve is set on the outer surface of the pup joint , wherein, said righting cover is provided with N air bag assemblies, said air bag assembly is made up of air bag 4, gas generator 5, igniter 6, and said igniter is connected with said gas generator, and said gas generator Located in the airbag, the igniter is connected to a power source through a control switch 7 .

[0025] Wherein, in the embodiment of the present application, the N airbag assemblies are evenly distributed in the righting sleeve.

[0026] Wherein, in the embodiment of the present application, the centralizing sleeve is cylindrical, and the centralizing sleeve is made of rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com