Novel throttle valve

A throttle body, a new type of technology, applied in the field of auto parts, can solve problems such as adverse effects on the engine, reduce air intake efficiency, adverse airflow stability, etc., to improve output power and fuel utilization, increase intake pressure, and layout requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

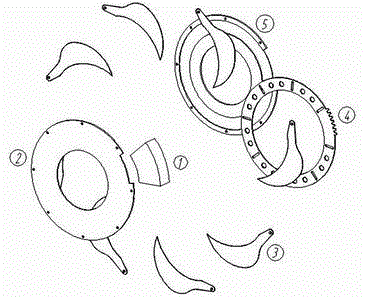

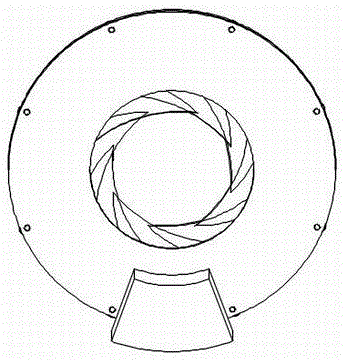

[0012] Such as figure 1 and 2 As shown, a new type of throttle body includes a motor 1, an upper base plate 2, a blade 3, a driving ring 4, and a lower base plate 5; the motor 1 is fixed on the upper base plate 2, and the driving ring 4 is placed in the ring groove of the lower base plate 5 , blade 3 is installed in the elongated groove of drive ring 4 and the round hole of upper base plate 2, lower base plate 5 by the concave platform on it, upper base plate 2 and lower base plate 5 are installed by bolts, and whole device is packed as a whole.

[0013] There are teeth on the drive ring 4, and the motor 1 drives the teeth on the drive ring 4 to rotate the drive ring 4, thereby achieving the purpose of opening and closing the lugs.

[0014] The throttle body of the present invention has a multi-blade rotary opening and closing structure, the configured blades are driven by a motor, and the blades rotate directly to produce an opening and closing effect, directly controlling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com