Hydraulic pipe-jacking grouting machine

A grouting machine and hydraulic technology, applied in roads, constructions, road repairs, etc., can solve the problems of destructive road conditions, high operating costs, and affecting normal traffic, etc., and achieve simple and convenient operation, low manufacturing cost, length and The effect of size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

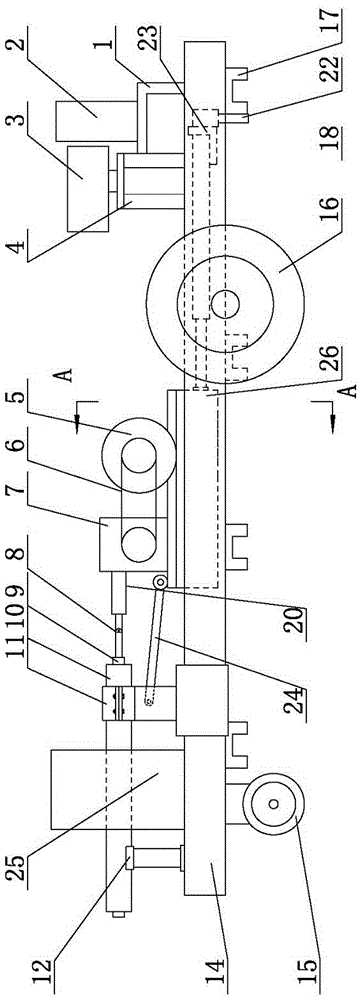

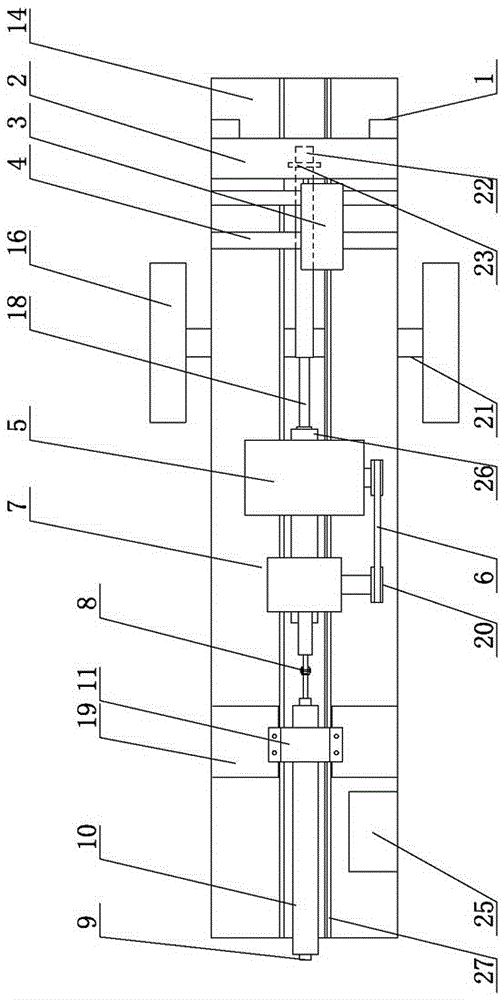

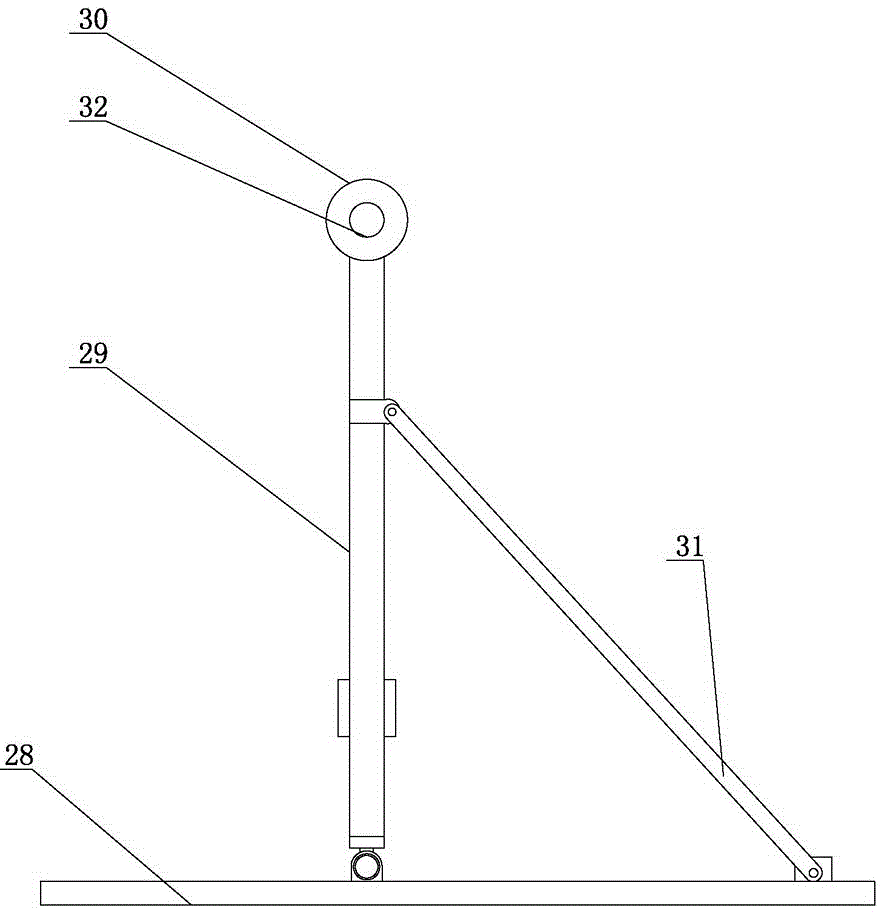

[0009] Stress testing platform of the present invention, such as figure 1 with figure 2 As shown, the frame 14 is included, and a guide rail 27 is respectively provided on both sides of the frame 14 along its length direction, and the guide rail 27 and the frame 14 can be made into one body. The hydraulic station 2 is installed at the rear of the frame 14, and the pipe card sliding seat 19, the motor sliding seat 26 and the hydraulic cylinder sliding seat 23 are installed successively on the frame 14 from front to back. Pipe card sliding seat 19, motor sliding seat 26 and hydraulic cylinder sliding seat 23 can slide along guide rail 27 respectively. To reduce sliding friction, such as Figure 7 As shown, the parts on both sides of the frame 14 can be made of channel steel, the channel steel is the guide rail 27, and the opening of the channel steel forms a guide groove inwardly, and the pipe clamp slide seat 19, the motor slide seat 26 and the hydraulic cylinder slide seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com