Small three-axis cradle head

A kind of PTZ, small technology, applied in machine/stand, optics, instrument, etc , Guaranteed operation and use performance, adjustable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

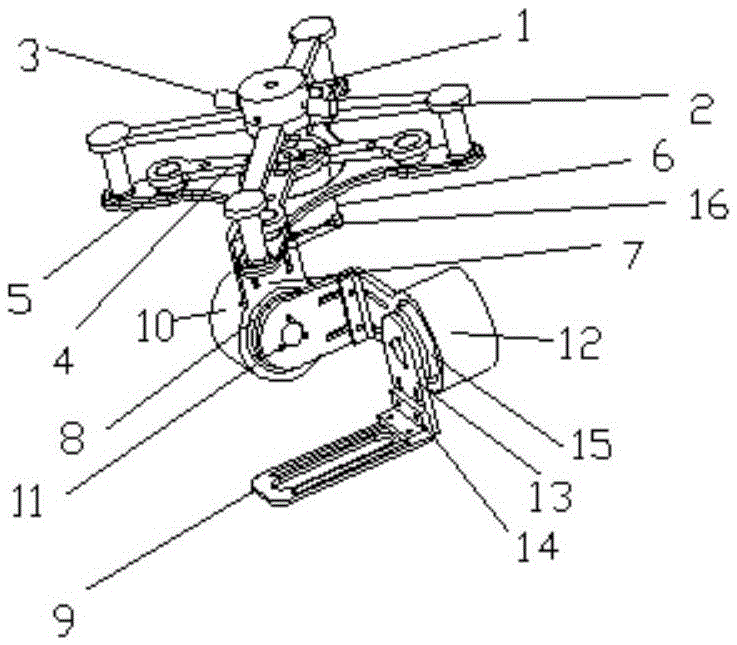

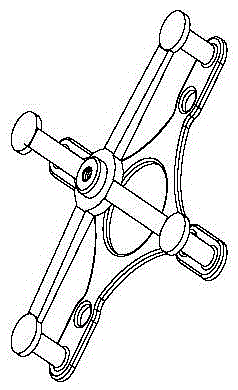

[0013] Such as figure 1 As shown, a small three-axis gimbal includes a first quick-release connector 1, a second quick-release connector 2, a fixing screw 3, a shock absorber 4, a shock absorber 5, a Z-axis motor seat 6, and a Z-axis Connecting plate 7, Y-axis motor 8, camera base 9, Y-axis motor base 10, Y-axis connecting plate 11, X-axis motor base 12, X-axis connecting plate 13, fixing frame 14, X-axis motor 15, Z-axis motor 16 , wherein, the first quick release connector 1 is installed on the second quick release connector 2, fixed by the fixing screw 3, the shock absorber 4 is installed inside the second quick release connector 2, and Four damping balls 5 are installed under the shock absorber 4, the Z-axis motor seat 6 is installed under the second quick release connector 2, and the Z-axis motor 16 is installed in the Z-axis motor seat 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com