Manufacturing method for performing type laser weapon and laser sword

A weapon and laser technology, which is applied in the field of performance laser weapons, can solve the problems of single application of laser swords, potential safety hazards, and high power consumption, and achieve the effects of not easily causing safety accidents, low cost, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

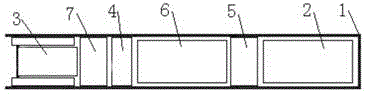

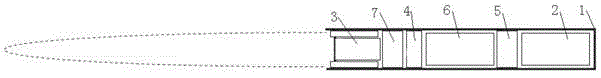

[0034] A method for preparing a show-type laser weapon, based on the holding part 1 of the weapon, making a body extending from the holding part 1, characterized in that it includes:

[0035] Step 1: install a light-emitting device 3 and a liquid atomization device 4 in the holding part 1 of the weapon from near to far from the body; the weapons include knives, swords, guns, etc. The holding part 1 of the weapon can be a hilt, a hilt, a gun body, etc., and the body corresponds to a sword body, a knife body, a gun body, and the like.

[0036] Step 2: The shape of the light beam emitted by the light emitting device 3 or the spray shape of the liquid atomizing device 4 is set as the shape of the weapon body; the light emitting device 3 can be set in the shape of emitting a sword body, a blade body or a gun body Light rays shining on the spray can form eye-catching, realistic and safe laser weapons.

[0037] Step 3: electrify the light-emitting device 3 or the liquid atomizing de...

Embodiment 2

[0039] A method for preparing a show-type laser weapon, based on the holding part 1 of the weapon, making a body extending from the holding part 1, characterized in that it includes:

[0040] Step 1: install a light-emitting device 3 and a liquid atomization device 4 in the holding part 1 of the weapon from near to far from the body; the weapons include knives, swords, guns, etc. The holding part 1 of the weapon can be a hilt, a hilt, a gun body, etc., and the body corresponds to a sword body, a knife body, a gun body, and the like.

[0041] Step 2: The shape of the light beam emitted by the light emitting device 3 or the spray shape of the liquid atomizing device 4 is set as the shape of the weapon body; the light emitting device 3 can be set in the shape of emitting a sword body, a blade body or a gun body Light rays shining on the spray can form eye-catching, realistic and safe laser weapons.

[0042] Step 3: electrify the light-emitting device 3 or the liquid atomizing de...

Embodiment 3

[0046]A laser sword, comprising a holding part 1 and a power supply device 2 arranged in the holding part 1, characterized in that it also includes a light emitting device 3 and a liquid atomizing device 4 electrically connected to the power supply device 2, The light emitting device 3 and the liquid atomizing device 4 are installed from near to far from the port of the grip part 1 . The light emitting device 3 can be arranged to emit light in the shape of the sword body, and irradiate the spray to form an eye-catching, realistic and safe laser sword. Because the sword body is formed by light irradiating on the fog, the sword body is very soft and safe, and can be extended and retracted instantly visually, without using high-power lasers, avoiding the difficulty in the process of use in the prior art Breaking or causing personal safety problems, the requirements for storage are not high, the use is simple and convenient, the cost is low, the production is simple, and it is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com