Printed circuit board smoothness detection apparatus with adjustable height

A technology for a printed circuit board and a detection device, applied in the field of auxiliary appliances, can solve the problems of template wear, lack of template, inconvenience in production, etc., and achieve the effects of accurate results, simple structure and simple detection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

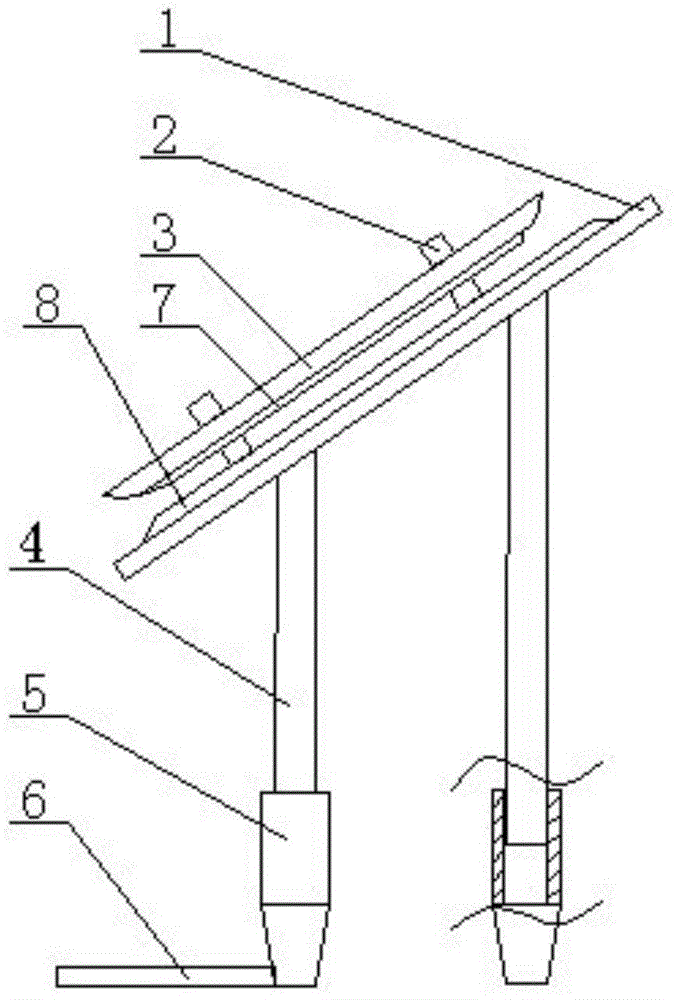

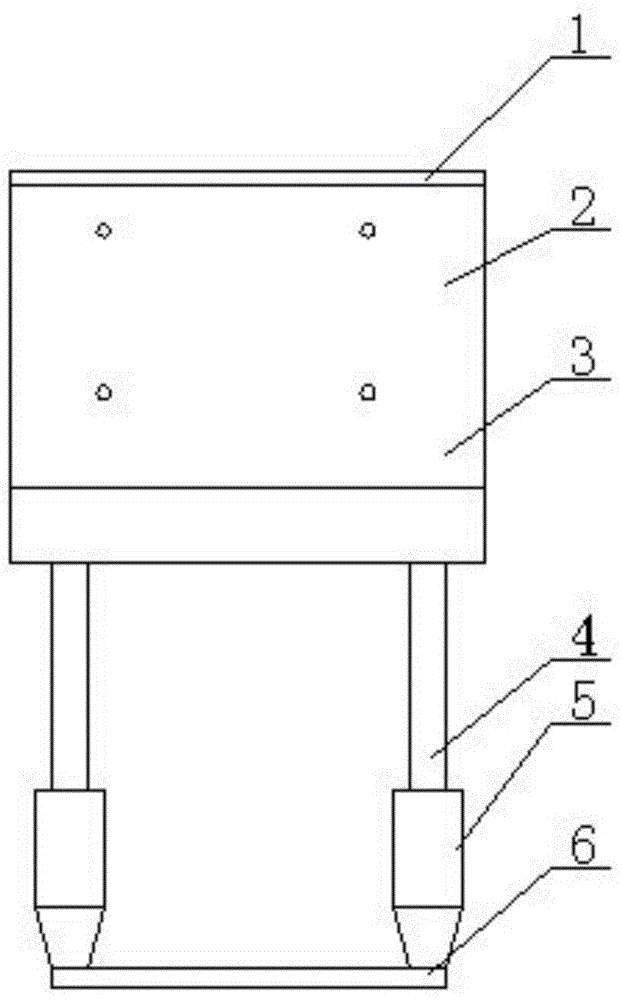

[0014] A height-adjustable printed circuit board smoothness detection device, including a square detection support plate 1, a square detection upper cover plate 3, a support rod 4 and a base 6, and the middle part of the upper surface of the detection support plate is fixed in parallel with bolts 2 at intervals. The four corners of the upper cover, the lower surface of the detection support plate are fixed symmetrically on the upper ends of four parallel struts, and the bottom ends of the two struts at the front end are fixed on the horizontal base, and the detection support plate is parallel to the detection upper cover And vertically inclined at a certain angle, the distance between the detection su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com