A Remote Reduction Furnace Flow Monitoring System

A flow monitoring and reduction furnace technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve problems such as difficulty in re-acquisition, unspecified correction coefficients, etc., to reduce pipeline laying costs, flow Effect of improved monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Such as figure 1 As shown, the remote reduction furnace flow monitoring system of the present invention is used to monitor the flow of a certain gas supplied to the reduction furnace, including a pipeline subsystem, an ultrasonic detection subsystem, and a processing subsystem, wherein the ultrasonic detection subsystem is set Inside the pipeline subsystem ( figure 1 It is schematically shown as being coupled with the pipeline subsystem), and the processing subsystem is used to obtain the flow monitoring information of the gas supply to the reduction furnace from the ultrasonic detection subsystem.

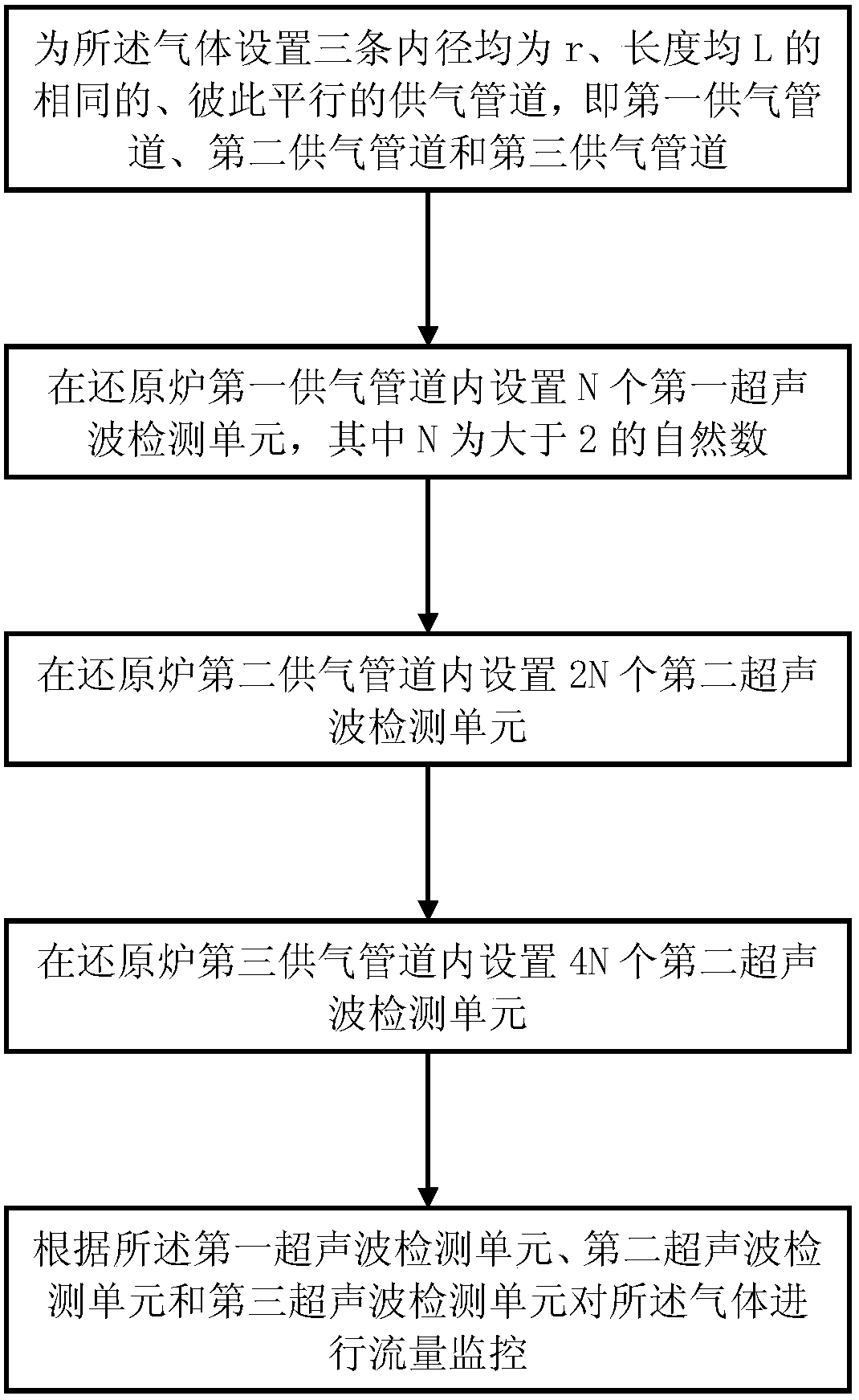

[0029] Wherein, the pipeline subsystem includes a first gas supply pipeline, a second gas supply pipeline and a third gas supply pipeline, and the first gas supply pipeline, the second gas supply pipeline and the third gas supply pipeline are used to supply the reduction furnace with Gases are provided, the inner diameters of which are r, the lengths are L, the material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com