An indoor test device and method for simulating car driving on road noise at micro-surface

A testing device and micro-surfacing technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problem of consuming a lot of manpower and material resources, and achieve the effect of saving resources and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

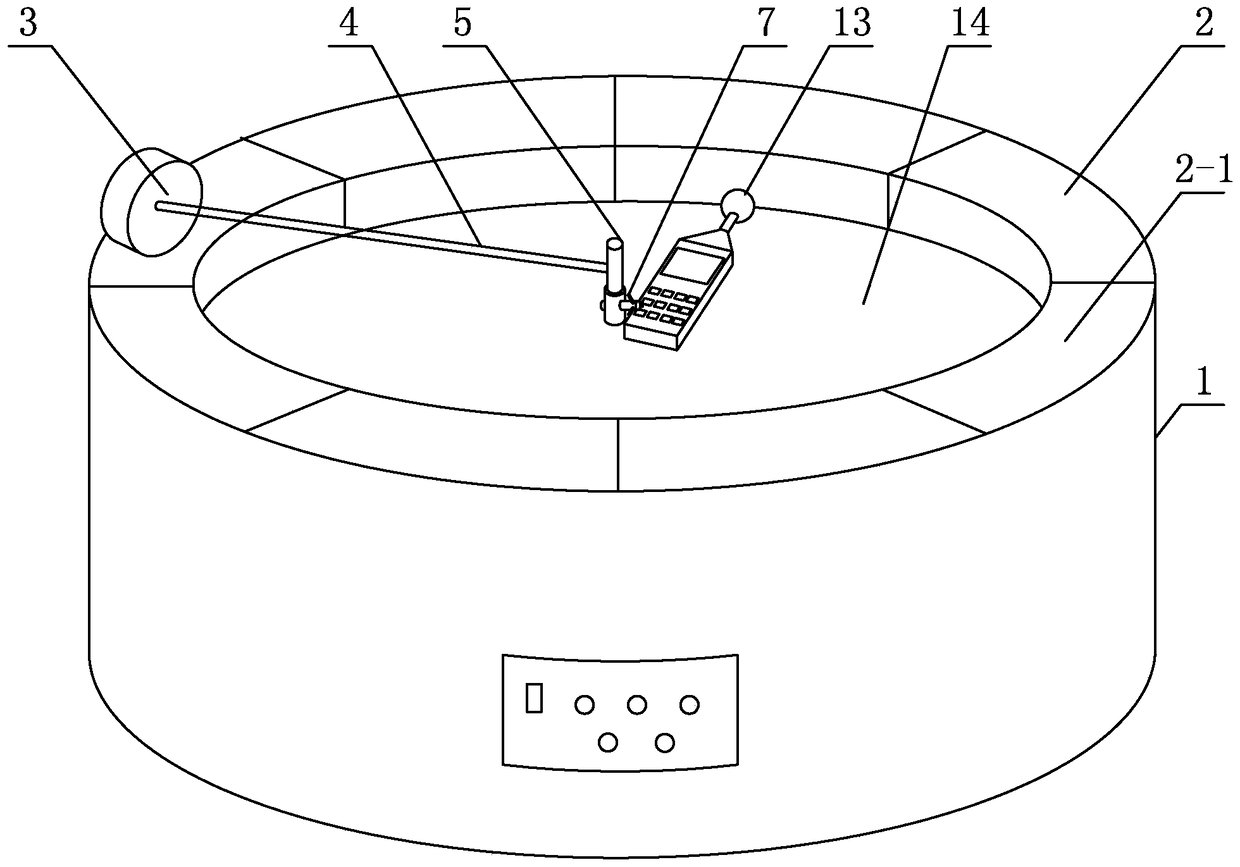

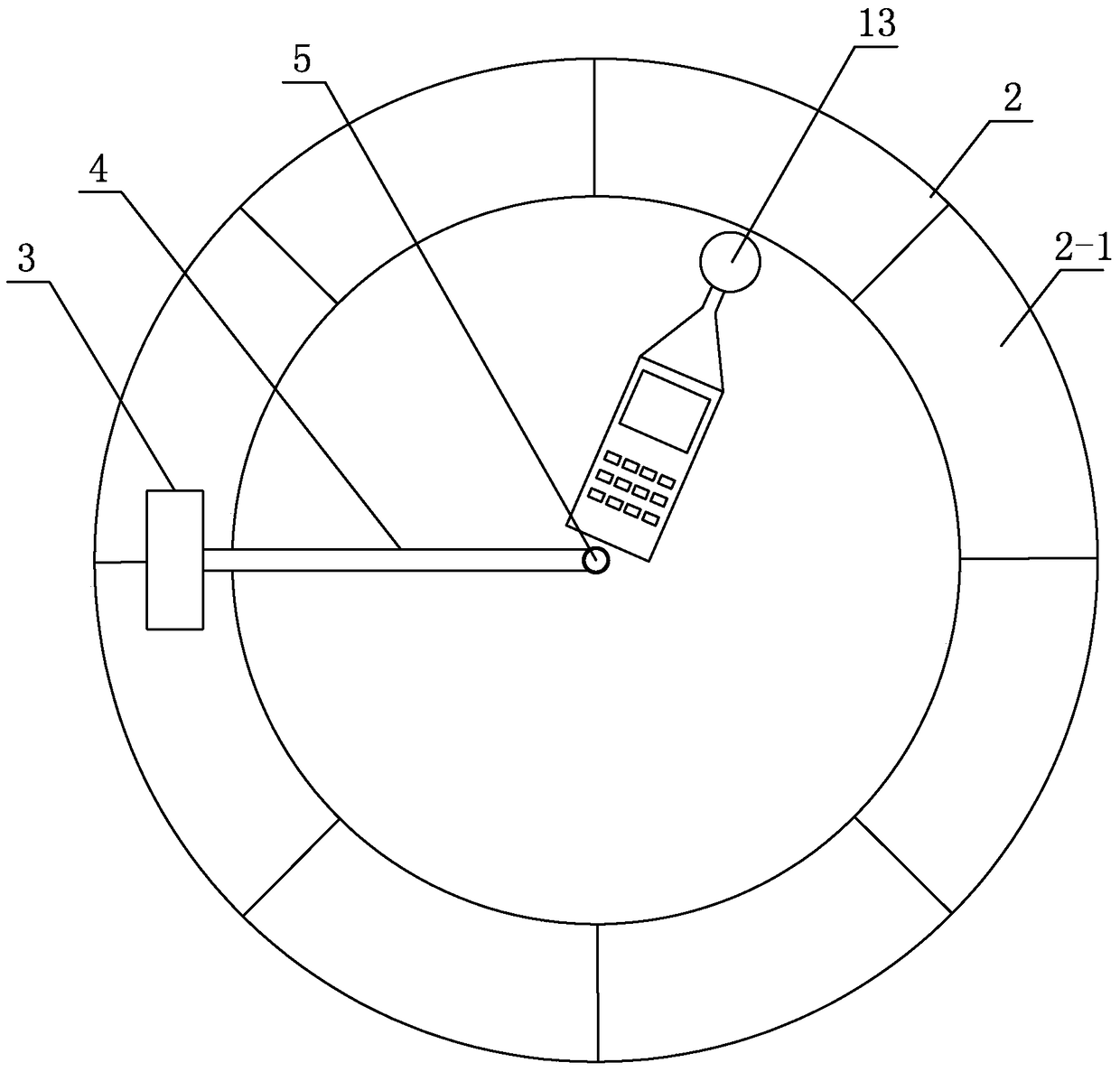

[0017] Specific implementation mode one: combine Figure 1 to Figure 4 Describe the present embodiment, the indoor test device for simulating the road noise of a car running on the micro-surface described in the present embodiment includes a base 1, a circular track 2, a test wheel 3, a horizontal shaft 4, a vertical shaft 5, a drive shaft 6, and a lifting vertical shaft. Shaft knob 7, driven gear 8, driving gear 9, hinged column foot 10 and motor 11, circular runway 2 are installed on the upper surface of base 1, engine 11 is installed in the base 1, and the lower end of drive shaft 6 passes through hinged column foot 10 is installed in the middle of the inner bottom surface of the base 1, the driven gear 8 is set on the drive shaft 6, the driving gear 9 is set on the rotating shaft of the engine 11, the driving gear 9 meshes with the driven gear 8, and the lower end of the vertical shaft 5 is lifted The vertical axis knob 7 is connected with the upper end of the drive shaft ...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 1 to Figure 4 Illustrate this embodiment, a kind of simulated automobile driving described in this embodiment is in the circular runway 2 of indoor test device of road surface noise at the micro-surface place is the circular runway 2 that is made up of eight test molds 2-1, and the upper surface of base 1 is provided with An annular groove composed of eight grooves 1-1, each groove 1-1 is respectively embedded with a test mold 2-1. With such a setting, on the one hand, it is convenient to disassemble and install the micro-surface, and on the other hand, it can carry out noise tests on various micro-surfaces or other mixtures at the same time. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

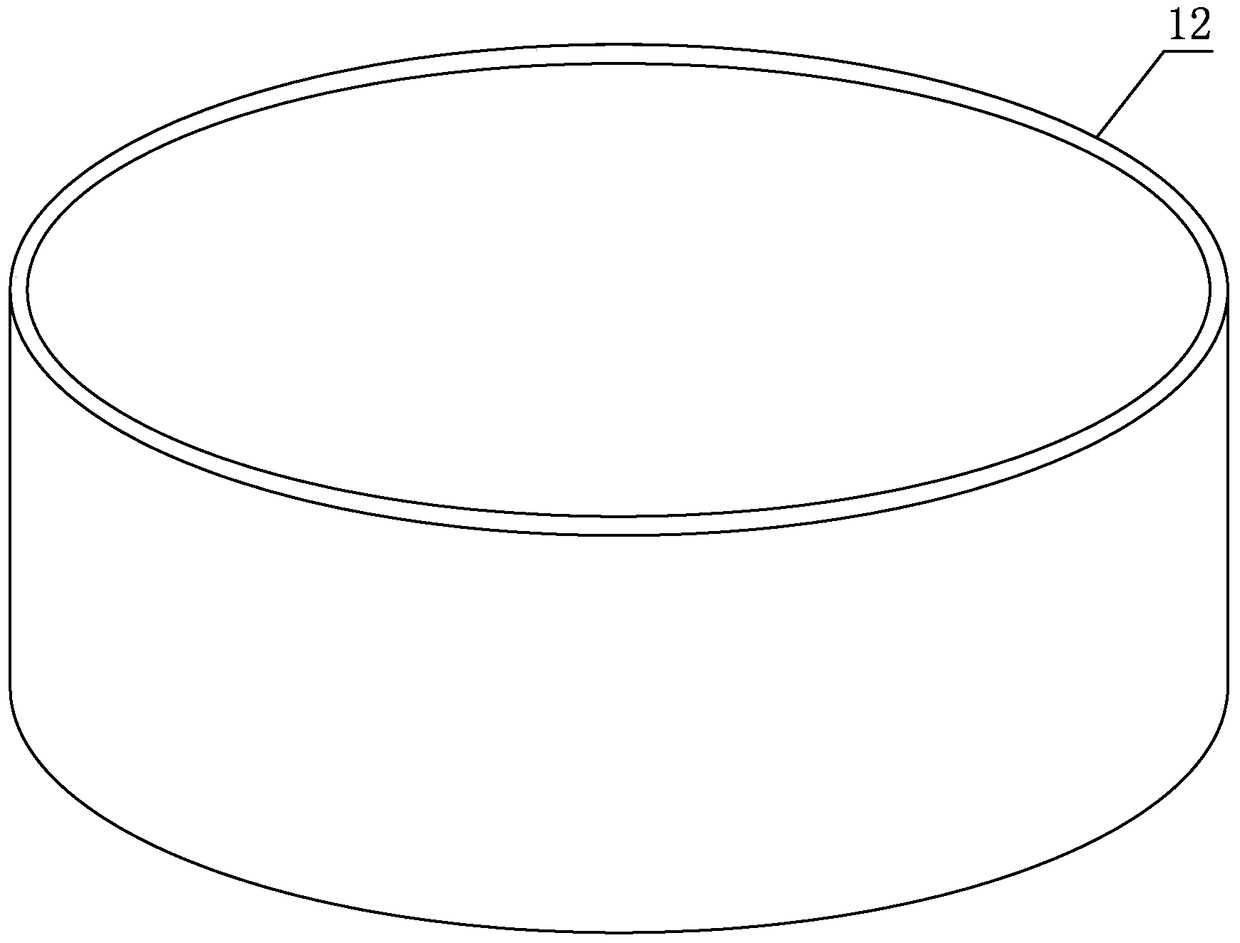

[0031] Specific implementation mode three: combination Figure 1 to Figure 4 Describe this embodiment, a kind of simulated automobile running in this embodiment described in micro surface place road surface noise indoor testing device also comprises sound insulation cover 12, and sound insulation cover 12 is fastened on the circular runway 2, and the inner sidewall of sound insulation cover 12 bottoms and The outer wall of the top of the base 1 is screwed. The height of the soundproof cover 12 is 40cm. Before the test starts, the soundproof cover 12 is buckled on the circular runway 2, and the soundproof cover 12 is tightened, and the soundproof cover is located on the control knob. Do it down, also keep the control knob from being blocked. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com