Anti-static equipment for production and processing

An anti-static and equipment technology, applied in the direction of static electricity, electrical components, etc., can solve the problem of poor static elimination effect, and achieve the effect of convenient disassembly and moving position, good static elimination effect, and reasonable equipment design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

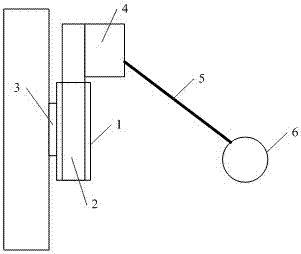

[0022] In Embodiment 1, anti-static equipment for production and processing is provided, please refer to Figure 1-Figure 2 , the equipment includes:

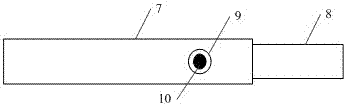

[0023] Cylinder 1, the upper end of the cylinder is provided with a rotating hole, the lower end of the rotating shaft 2 extends into the cylinder through the rotating hole, the rotating shaft is slidingly connected with the cylinder; the side of the cylinder is connected There is a magnet block 3; the upper end of the rotating shaft is connected to the back of the ion blower 4, the front of the ion blower is provided with N screw holes, the N is a positive integer greater than or equal to 10, and one end of the connecting rod 5 is threaded. The threaded end of the connecting rod is inserted into the screw hole to be connected with the ion blower, and the other end of the connecting rod is connected with the antistatic bracelet 6; wherein, the connecting rod includes: a first cylindrical rod 7 and a second round Cylinder rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com